What is the name of the wooden tool box. It is easy to store tools: we make a wooden box with our own hands. Universal case made of plastic canister

Reading time ≈ 5 minutes

A real owner always takes care of the safety of his tools. Even a small set should be stored in an orderly, neat manner. A skilled craftsman can assemble a container for tools and fixtures on their own. Below we will talk about how to make a tool box with your own hands. The presented photos and videos will help in the work.

Outwardly, the box looks solid and stylish, it immediately declares a serious approach to the life of its owner. Its dimensions (70x40x45 cm), i.e. 70 cm wide, 40 cm deep, 45 cm high. This is quite enough to accommodate a hand tool. The drawer has 3 drawers, as well as a top hinged lid that opens up a spacious compartment. This box allows you to protect tools from dust, organize safe storage.

Required Tools

To make a wooden box, you will need the following tools:

- a circular saw;

- milling machine;

- grinder;

- clamp;

- a hammer;

- wire cutters;

- file;

- wood saw;

- chisel.

Step-by-step instructions for making a tool box

The optimal material for the manufacture of the frame is oak wood. This is an excellent durable material, which is durable and resistant to mechanical stress. It is better to take as a basis - glued boards with a thickness of 19 mm. This material does not have knots and rotten inclusions. With the help of a circular cut a strip 38 mm wide.

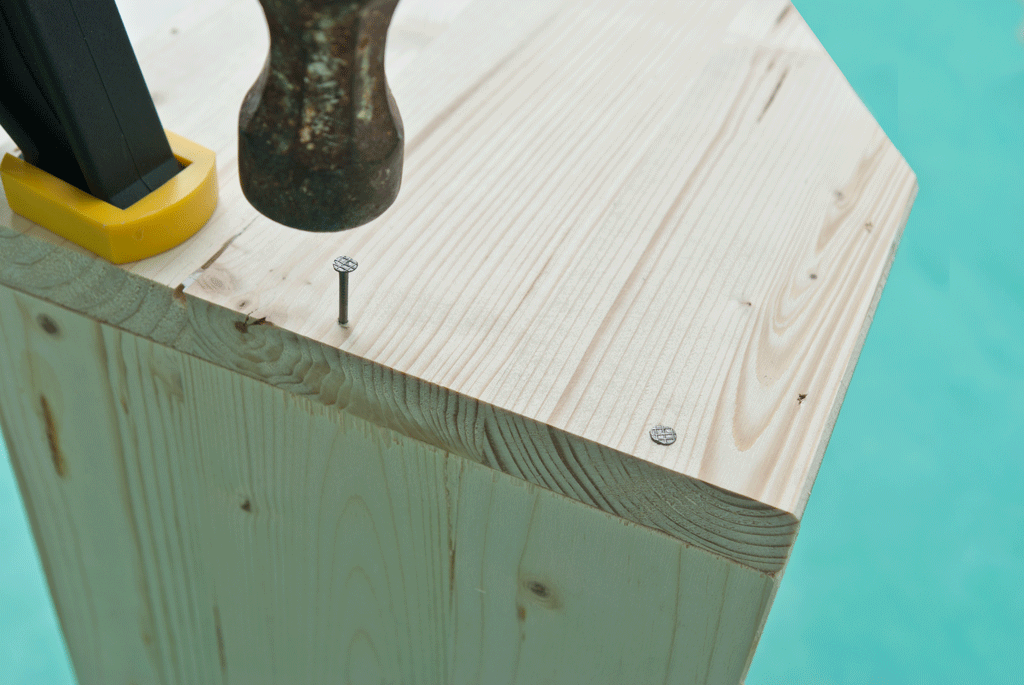

So that when gluing the individual elements do not move relative to each other, a carnation is driven into the first part a little, its cap is removed with wire cutters, and then a second board is stuffed onto the protruding sharp tip.

The boards are additionally coated with glue and fixed.

The glue that has come out at the joints of the parts is removed with a chisel, you just have to wait for the glue to dry a little.

The result should be a 38x38 mm part. Its butt is polished.

The edge must be cut strictly at an angle of 90 °, so when cutting the part to the desired length, one must not forget about the cut angle.

This technique will help to ensure the accuracy of the cut angle.

The location of each part is marked so as not to get confused during assembly.

A groove is cut in each part along the entire length, it must go strictly in the center.

The grooves can be made either with a stationary circular saw or with a milling machine.

On parts that are intended for the manufacture of vertical corner supports of the frame, transverse markings are made.

Another longitudinal groove is made in the rear corner parts. It is not needed in the front corner bearings.

For subsequent fastening in the end part of the blanks, you need to find the center, noting the point of intersection of the diagonals.

It is necessary to carefully check the compatibility of the blanks.

The blanks are processed with a file.

In a freely assembled frame, marks are made to subsequently lengthen the grooves.

The grooves are cut with a hacksaw for wood.

Remove all excess with a chisel.

These blanks are needed for drawers. A corner is sawn from the end part.

Each blank is drilled for bolting.

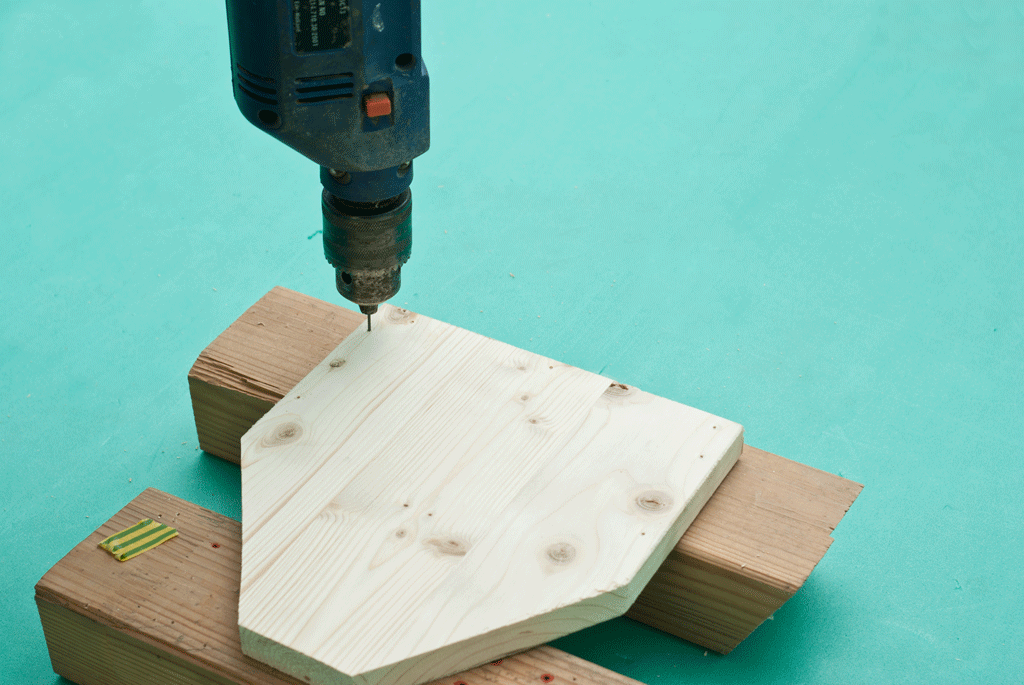

Observing accuracy, it is necessary to drill the prepared parts.

The part intended for fixing and dividing 2 drawers is cut out at an angle of 90°.

Having installed the details for the movement of the boxes in place and fixing them, they gradually begin to screw them.

The corners of plywood blanks are cut off, as in the photo.

The walls of the lower drawers are attached to plywood sheets with self-tapping screws.

Prepared horizontal plywood parts are attached to one side. First, this is done without the use of glue.

During fixation with clamps, it is necessary to check the diagonal so that the dimensions match.

Drawers are made from plywood.

The grooves can be cut either on a stationary saw or with a milling cutter.

Details of drawers are fastened with glue.

The side parts of the boxes must have grooves for movement along the planks fixed inside.

For strength, the side parts are fastened with dowels, which are cut flush.

For reliability when gluing, small carnations are partially driven into the surface of the front wall of the drawers, their caps are removed.

After attaching the front panels to the drawers, they look to see if the individual elements are evenly positioned.

When gluing, it is necessary to observe the utmost accuracy, there should be no gaps.

At the end, the top frame of the box is made of plywood.

To make a precise cut at a 45° angle, it is advisable to use a special tool.

The blanks for the frame are connected and fixed when glued using a tension belt.

Home instruments have an amazing ability to get lost at the most inopportune moment. If hammers and screwdrivers are used periodically, they are stored anywhere: mezzanines, cabinet shelves, balcony.

Therefore, when the wife asks to hang a shelf, remembering exactly where the drill and self-tapping screws are located will be problematic. It is much more practical and efficient to store tools in a special box, which can be purchased ready-made or made by hand.

What to choose

We note right away that the tool box can be different, and the shape and dimensions directly depend on what is supposed to be stored inside the case.

For hand tools. Usually this is a rectangular design with a handle, where the interior space is delimited into one large compartment and 2-3 smaller compartments. It is convenient to store hammers, screwdrivers, fasteners here.

For power tools. Such cases are usually produced by the manufacturer of the instrument itself. Standard option: a portable box, where one cell is reserved for a power tool and exactly repeats its shape, the rest are intended for equipment: drills, batteries and other things.

Organizers. These are modular designs, consisting of several drawers of various shapes and sizes. Such options are suitable for professionals and home craftsmen, they are easy to store and transport, help to quickly find any little thing.

When the problem of tool storage arises, the first thing that comes to mind is to purchase a ready-made box in the store. However, this is not the best option. The fact is that factory designs are focused on the average buyer, so they may not be suitable for a specific model of grinder or drill. In addition, the number of tools is usually added and the interior space becomes small.

To avoid these problems, you can make a tool box yourself with a little effort and creativity.

From the boards

If there are few tools, they are used periodically and only for home use, it makes no sense to manufacture a complex structure. It is enough to make an ordinary wooden box from boards so that screwdrivers, hammers and self-tapping screws are simply in one place, and not lying around the whole apartment.

Given that we are talking about an elementary product, you can do without a preliminary drawing. The main thing is to decide on the size of the sides. For the material of manufacture, it is better to choose a softwood edged board: this is the most affordable option that is easy to process.

The homemade box consists of 5 parts:

- 2 side walls;

- 2 end walls;

The elements are cut out in accordance with the planned dimensions, treated with sandpaper and fastened together with self-tapping screws. For greater reliability, the side parts can be fixed with metal corners.

Such a homemade wooden box is inconvenient to carry, but it will help to store tools in one place and not look for them all over the apartment. It can be put in the trunk of a car, on a storage shelf or in a garage. Sizes vary depending on what exactly is supposed to be stored inside.

From plywood

DIY plywood tool boxes attract attention with an interesting design. They are easy to use and emphasize the professionalism and qualifications of the home master.

A convenient plywood box with a handle will consist of the following items:

- bottom - dimensions 450 * 200 mm, a shallow groove is cut in the middle for a transverse partition;

- walls - cut out in the amount of 4 pieces. A groove is also cut in the middle of the end elements;

- transverse rack - recommended height 400 mm, length adjusted to the width of the bottom, taking into account the sidewalls. The upper corners of the rack are sawn off to make a trapezoidal shape.

The assembly is carried out according to this scheme. To begin with, the body elements are glued together, tightly pressed against each other. While the glue dries, a hole is cut in the transverse rack, which will act as a handle, wooden dies can be glued in the upper part for ease of grip. Next, the rack is installed in pre-prepared grooves, fixed with glue.

After completion of the work, a plywood box for tools is obtained, convenient for carrying. However, the design can be made more functional. To do this, wooden dies with pre-drilled holes are glued to the transverse partition, where you can place screwdrivers, pliers, side cutters and other tools necessary for doing homework.

To prevent the box from drying out, it is covered with several layers of varnishes. For greater reliability, if desired, the bottom is fastened to the walls with corners.

Transformation into a stool

From plywood and wooden blocks, you can make a portable tool storage box, which, when turned upside down, will turn into a simple stool or stand for working at height. This universal design is made according to this scheme.

The bars are cut according to the given size. They will serve as legs and be tilted. To make the stool stable, the upper and lower ends are cut off at an angle of 15 degrees.

Sheets of plywood are nailed to the legs, which will become the end walls. The recommended width is 360 mm, the height is selected in such a way as to completely hide the legs without protruding beyond them.

The side walls are cut out of plywood, occupying about half the bar in width. The edges of the rectangle are cut at an angle to exactly match the angle of the legs.

The cover is made rectangular, attached to the ends of the racks with self-tapping screws.

After the work done, turn the resulting stool upside down, turning it into a deep box for storing tools. To make the structure convenient to carry, a wooden block is cut out, which in length will correspond to the distance between the walls. They round off sharp corners, screw the bar with self-tapping screws and get a convenient handle, which additionally acts as a stiffener.

drawer organizer

This is a more complex design, but it is ideal for storing large tools and additional small things: fasteners, corners, studs and much more. At first glance, such boxes seem to be a complex mechanism, but in fact they can be made on your own, spending a little free time.

The manufacturing process is conditionally divided into 3 stages:

- assemble the body. This is a deep plywood box with an open top, which is designed to store a large tool, such as a grinder, screwdriver or electric drill. However, you can do the opposite: delimit the internal space into several sections with wooden dies and store bolts, nuts and self-tapping screws here;

- additional boxes. There will be 4 of them, and they are installed on top of the main box, which must be taken into account when determining the dimensions. Additional drawers should not go beyond the boundaries of the base. To give the structure a complete look, the upper boxes are equipped with lids;

- separate elements are combined into a single whole. To do this, the organizer is assembled into a finished form, markings are made on the walls for installing metal plates: 3 pieces for a group of boxes on each side. Then, in accordance with the markings, holes are drilled where the bushings are installed.

To make the organizer easy to carry, the top drawers can be additionally equipped with handles.

Note that the simplest options are given here. With a little effort, you can turn an ordinary toolbox into a work of art that will become a real decoration of the garage, country house and city apartment.

This article is about how to make a wooden tool box. If you have a lot of tools and want to keep them organized, the best thing you can do is to create a simple wooden box. From our experience, we find them very useful as they are lightweight, durable and provide plenty of storage space for tools. Don't forget that you can adjust the size and design to suit your needs.

The main components of the toolbox are made from 20mm planks, as they have a beautiful appearance and are very durable. In addition, we recommend that you glue the joints and fasten everything with self-cuts. Try to screw in the screws as symmetrically as possible.

Upon completion of the assembly, it will be necessary to sand the entire surface of the box. Make sure all edges are smooth. Otherwise, you may injure your hands on sharp edges. Also, be sure to check that the heads of all the screws are flush with the wood surface. Get rid of dust and chips before painting.

What you need to make a wooden tool box

In order to make a wooden tool box, you will need the following:

materials

Instruments

- protective gloves, goggles;

- ruler, ;

- crayon, tape measure, level, carpenter's pencil;

- and drills.

Adviсe

- Pre-drill holes in wooden components before tightening screws.

- Make a handle out of a cylindrical stick.

Time

- 1 hour

Drawer decoration

Making a simple wooden toolbox is one of those projects that can be done in less than an hour. But it can make your life easier, especially if you work with tools a lot.

Smart Tip: Before joining the parts, add some glue to the joints. Immediately remove excess adhesive with a dry cloth, otherwise it will be difficult to remove after drying.

The first step of the project is markup. As you will see in the next step of the project, we will be using 1x8 boards to make the tool box. Therefore, you should use a carpenter's pencil and square ruler to mark lines on wooden boards.

In order to get accurate cuts, we recommend using a jigsaw or a good circular saw. Make sure the saw has smooth teeth or it may tear off the edges.

Smart Tip: Also, check that the blade will pass exactly along the cut line before sawing.

In the picture, all the components needed for the box. A circular saw can make the job easier, as many of the cuts need to be made at an angle.

You must use this blueprint when crafting crate components. Make sure you double check all measurements otherwise the components may not match.

After creating the wood pieces, you need to drill holes around the edges. As you can see in the picture, you need planks on the wood block to prevent damage to the surface. Drill three holes on the bottom and two holes on the sides.

Smart Tip: If you are not experienced in woodworking, you should draw guidelines for pilot lines. Indent from the edges to prevent splitting of the wood.

If the bottom edges are not smooth, you should carefully sand them with 120 grit sandpaper before assembling.

Coat the bottom ends with wood glue to strengthen the connection. Remove excess glue with a dry cloth, otherwise you will waste time cleaning it.

Press the components firmly and leave for half an hour. If you use good glue, it will hold the joints together well.

Still, screw the self-tapping screws into the drilled holes anyway.

In order to obtain a solid construction, we recommend using self-tapping screws. Work carefully to prevent damage to wooden components.

Smart Tip: Align all parts before twisting. As you can see in the picture, the edges should be even.

After installing all the components together, the tool box should look like the one in the photo below.

Make a handle out of a cylindrical wooden rod. Handle diameter is approximately 20-25 mm.

Smart Tip: Use a ruler to cut the rod to the desired length.

Add some wood glue to both ends of the rod before pushing it back into place. Then drill a hole and screw in the screw. Hold the handle while twisting, otherwise it may move out of place.

Smart Tip: Leave about 15 mm from the top edge to the wooden handle.

Don't forget to smooth the edges of the wooden components with sandpaper.

Smart Tip: Clean the box of dust and chips before painting.

After completely sanding the entire surface of the box with sandpaper.

Smart Tip: Apply multiple coats of paint, varnish, or stain to enhance the look of the wood and protect the materials from rotting.

If you want your box to have the same dimensions as in our article, we clarify that 1 inch equals 2.54 cm.

Hello everybody!

A toolbox today is a very indispensable thing for every owner. Most of us have a lot of different tools that we may not use very often, but nevertheless, we keep them, since not one repair can do without them. In order for the tool to be in one place, and it was convenient to transport it, we use special boxes. Often we just buy them in the nearest store, the range and variety allows us to do this. But why not make it yourself? The manufacturing process is not too complicated, anyone should be able to handle it, especially with a handmade thing, which is much more pleasant to use than a purchased option. This article will describe 4 different ways to make boxes, a photo report is attached.

Let's start making!

Manufacturing Method No. 1

We will need:

Material

Plywood;

- pine board;

- nails;

- wood glue.

Tool

- drill;

- a hammer;

- chisel;

- manual frezer;

- ruler;

- pencil;

- roulette.

The first step is to find the necessary material, plywood or trimming boards are suitable for this. Further, according to the presented drawing, it is necessary to mark up, then cut out all the details of the case. It is necessary to make special grooves into which the partition will be placed, for this we use a manual milling cutter, or another available tool.

The diagram shows the following body parts:

1 - wall (2 pcs.);

2 - sidewall (2 pcs.);

3 - bottom;

4 - groove along the thickness of the partition and a depth of 1/2–1/3 of the thickness of the material

When everything is ready, all elements of the box body should be sanded. Next, we assemble the body together, fix the parts with wood glue, and then additionally fasten with small nails.

Now we make a partition for the box, cut out a special handle, for this we use a jigsaw.

When the partition is ready, grease the grooves with wood glue and install it in its place.

Next, from the planks we make overhead handles, with the help of a planer we round the corners. Then we make tool holders from the rails, use a jigsaw, and a drill. The holes will serve for screwdrivers, and pliers, etc. will be installed in square cutouts. tool.

In order for the box not to get dirty, and to be protected from the environment, we cover the surface with varnish. As a result of the work done, we get such a homemade box.

Manufacturing method No. 2

Drawer-stool

Material

Plywood or OSB;

- wooden beam;

- self-tapping screws;

- wood glue.

Tool

Available cutting tool;

- screwdriver;

- ruler;

- pencil;

- roulette.

We take an existing sheet of plywood, make markings on it, and, according to the dimensions presented, cut out the lid (Fig. 1), then the longitudinal drawers (Fig. 2) and sidewalls (Fig. 3).

Next, we take a wooden beam with a section of 40x50 mm, cut out a handle, and 4 legs with bevels at the ends at an angle of 15 °.

Next, we assemble the structure together, using self-tapping screws as fixing elements.

Parts layout:

1 - cover;

2 - tsarga;

3 - handle;

4 - leg;

5 - sidewall.

When everything is ready, use sandpaper or a grinder to round off sharp corners and clean the surface. Next, you can apply a protective coating.

The end result should be such an unusual tool box, which, if necessary, can be transformed into an ordinary stool, for this it is enough to turn it over and put it on legs, with it it will be convenient to reach the place we need, at a time when growth does not allow do it.

Manufacturing method no. 3.

Box for the young master.

Does your child love to craft? We offer to make a small box with him, where he will store his favorite tool.

To make a box with our own hands, we need the following

Material

16 mm boards;

- round wooden beam;

- self-tapping screws;

- wood glue.

Tool

Available cutting tool;

- screwdriver;

- ruler;

- pencil;

- roulette;

- clamps.

First you need to take the existing boards with a cross section of 16 mm, then we make the markup, according to the dimensions provided, after which we cut the wood into the component parts we need.

The drawing shows the following details:

1 - sidewall;

2 - bottom;

3 - handle;

4 - handle stand;

5 - holder.

Using sandpaper, we grind the surface and remove sharp corners. When everything is ready, we begin to connect all the parts together, first you need to connect the bottom and sidewalls, then we put vertical racks along the marked lines and at the same time we put a horizontal handle.

We fix everything with glue and screws. Then we install special holders for screwdrivers.

Now you can paint, choose the color and coating at your discretion.

The toolbox is ready.

Manufacturing Method No. 4

The next version of the tool box is well suited for carrying various and necessary equipment for us, its appearance will be distinguished by solidity and reliability.

To make a box with our own hands, we need the following

Material

The board is not thicker than 12 mm;

- self-tapping screws;

- joiner's glue;

- pen;

- corners 8 pcs.;

- latch 2 pcs.;

- loop 2 pcs.

Tool

Available cutting tool;

- screwdriver;

- ruler;

- pencil;

- roulette;

- clamps.

For the manufacture of the box we use such wood as: pine, linden or poplar. The most optimal thickness of the boards will be a thickness of 12 mm.

Next, we make the markup, according to the indicated dimensions in the drawings, after which we cut it into its component parts, as shown in the photo.

Full list of required parts.

In order to make sure that the wood was cut correctly, you need to put all the parts in a single box.

First, we assemble the bottom part and the lid of the box, for convenience we use clamps and corner clamps. We fix the parts together with carpentry glue.

Then, using a drill, we drill a hole for the self-tapping screws, we drill the holes.

- Types of convenient boxes

- Material selection

- Stool-like box

- Small portable option

The master always has his own tool at hand. It allows him to quickly cope with the tasks. There are not many tools. Sooner or later there are so many of them that no pockets are enough to spread out all the screwdrivers and rulers. Need a box. You can't store them in a mess. Impacts, friction - drills become dull and quickly fail. In the process of work, there is not always time to look for the right screwdriver, so the space of a capacious wooden storage should be used, and the entire volume should be distributed into separate compartments.

The easiest way is to buy a container made of plastic or iron. Inside the finished models, the storage place for tools has already been thought out in advance, divided into several compartments. But a homemade box is assembled for each specific master, taking into account storage places for tools, consumables and fasteners. Some will fit the simplest models, others will need a multifunctional portable case. It makes sense to find out what types of portable storage exist in order to choose the right model, and then construct one with your own hands.

Types of convenient boxes

According to the form of manufacture and purpose, tool boxes are classified:

- Portable.

- Stationary.

- Special.

Portable containers for carpentry tools - compact models, inside of which a small number of things needed in the work are placed. The complete set of the case depends on the specialization of the master. Its design assumes a strong lock that will not open during long transportation. The portable box is constantly in motion, so it is important that several types of fasteners, convenient niches are thought out inside it, in which you can, for example, lay screwdrivers and fasten them so that they do not hang out or knock.

It is quite difficult to make a stationary tool box with your own hands. And all because its design is much more complicated than that of a portable one. Inside, you do not need to think over the arrangement of fasteners. The main thing is to form certain compartments and divide them into groups.

A special case is made according to strictly individual needs.. It can, for example, store only drill bits or wrenches of various sizes. Such a box for small tools is more convenient than universal storage. To perform work, sometimes the master needs to take several special cases with him at once. Before proceeding with the manufacture of storage, you need to decide which option is most suitable for the job.

For this you need:

- inventory of available tools;

- sort them into groups;

- distribute by size.

Then it will immediately become clear which box is best made for tools. The article has several instructions that will help solve this problem. First, it is important to choose a material that will be easiest to work with.

Material selection

The hardest thing is to make a tool box out of metal. Such material is not suitable for a portable design - the case will turn out to be too heavy. For stationary models in which iron keys or heavy components will be stored, it will do. During work, welding will be required. If you have the skills and ability to use it, you can try. If they are not there, plywood 8-10 mm thick can replace the metal.

It only looks fragile, but it is a very durable material. The parts are fastened together with screws and additionally coated with PVA glue, as they quickly become loose. For the construction of the frame, it is better to use hardwood bars. The walls of the case must be thicker - at least 10 mm. Boxes with cells for carpentry tools are best made from plywood 8 mm thick.

The mobility of stationary plywood boxes will increase markedly if rollers are attached to the bottom, which can be bought at a furniture store.

Boxes for various tools made of wood - carpentry classics. This material allows you to create any models with your own hands.

Case for storing small tools

If you need to have a set of small tools on hand, you can get by with a simple box with a handle. The process of its manufacture must be divided into several stages:

- The first stage is planning, making general calculations, drawing. It should display the order of subsequent actions. The drawing is drawn up independently, or you can use computer programs.

- The second stage is the preparation of the necessary building materials. These are wooden sheets 10-15 mm thick, nails, fasteners. For work, you may need measuring instruments, a hacksaw and a hammer.

- The third stage is production. Using the instructions, you can assemble a simple open tool box with your own hands (photo).

Before starting work, you need to make a drawing.

- Number 1 - the walls of the box (two pieces).

- Number 2 - sidewalls (two pieces).

- Number 3 is the bottom of the box.

- Number 4 - a groove made along the thickness of the partition. Its depth should be equal to one third of the thickness of the plywood.

All parts with a hacksaw are cut from plywood blanks. Then the edges of the workpieces are polished with sandpaper. A box is assembled from the largest parts, its sides are coated with PVA glue, then they are additionally fastened with small nails (it makes no sense to use bolt fastening here). The handle-holder (it is also a partition) is made according to the following scheme:

Plywood with a thickness of 5 mm is selected. The hole for the handle is cut with a jigsaw. The workpiece is inserted into the grooves made, which are pre-coated with PVA glue. To prevent the handle from cutting your hand, you need to take a bar with a section of 20x45 mm. The planer rounds the edges of the bar. A slot is made across the entire width, into which a plywood blank is simply inserted. In the end it should look like this.

Along the edges of the plywood handle (this is clearly visible in the photo), wooden slats are attached, in which notches-holders for pliers, pliers, wrenches or screwdrivers were previously made. The toolbox is ready. So that it does not get dirty, you need to paint it in several layers with wood varnish.

Using the same plywood, you can make a large box with your own hands, which with a slight movement turns into a stable stool. This was invented by craftsmen working with carpentry tools. You can take this drawing as a basis.

For these parts, it is required to make four legs measuring 375x50, with bevels at the ends, made at an angle of 15 degrees. And another handle 660 mm long and 40 mm wide. Along the edges - the same bevel. And here is a visual plan of its assembly.

The stool is assembled according to the proposed scheme, the parts are fastened with 4.5x60 mm screws, and not with self-tapping screws. At the final stage, such a box is obtained. Make it yourself - simple, as a result - a multifunctional storage for tools. If you turn it over, you get a stable stool.

Small portable option

There is the easiest option for making a box that is suitable for the average homeowner. Outwardly, it will look like in the photo.

A detailed drawing is attached to the model:

Number 1 indicates the sidewall, number 2 - the bottom of the wooden box, number 4 - the handle stand. The handle itself is a bar measuring 382 by 30 mm. Another detail is the holder - a rectangle 118 mm wide and 55 mm long. Three identical holes must be made in the holder. For this, a drill is used. The assembly of a large box begins with the connection of the bottom and sidewall, then the handle stand is mounted. The photo shows all the stages of the upcoming work.

Then the second rack is installed, and at the same time the park-holder is inserted into the blind holes. Then fasteners for screwdrivers are mounted. This is what should end up happening.