What kind of drill to drill for euroscrew. Furniture coupler: types and methods of application

Hello, friends.

Today we will talk about the most used fasteners for the manufacture of cabinet furniture.

The fastener, known as confirmat, has gained immense popularity among furniture makers since the 1990s. Its exact name is a single-element screed.

It is also called a euroscrew, a euroscrew and is colloquially called "Eureka", and the strange name confirmat comes from the name trademark Confirmat used to produce these products by a German company Hafele.

Features and Benefits

The size range of this fastener is presented in the following ratios of the outer diameter of the thread and the length of the screw (mm): 5x40, 5x50, 6.3x40, 6.3x50, 7x40, 7x50, 7x60, 7x70.

The most popular are confirmations 50 and 70 mm long with a thread diameter of 7 mm.

Regular head Euro screws require additional countersinking of the hole to get the head flush, but they are also available with a small tooth under the head that provides the hole with a chamfer right size just during installation.

If the confirmation is mounted from the side of the front surface of the furniture body, then today a wide choice is offered to mask the screw heads, which can be selected in accordance with the decor of the furniture material.

Nuances of fasteners

With all the versatility of this fastener and the ease of working with them, a certain skill is required, mainly associated with knowledge of the characteristics of a particular material to be installed.

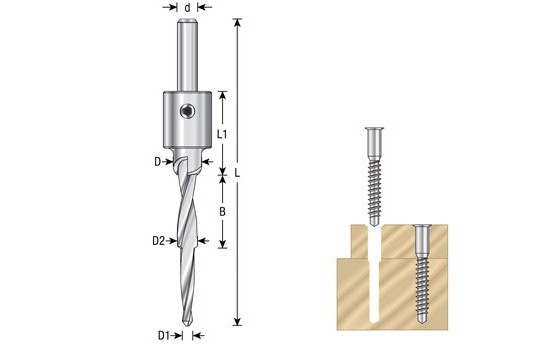

Holes for confirmations can be made using drills with a diameter of 4.5-5 mm under the screw shaft, and a hole for the head is made with a special stepped cutter mounted on the drill.

The latter option is the most convenient, as it allows you to prepare holes in one pass.

To make a quality hole, it is better to use a high-speed one. At low speeds, the drill can pull the wood and become clogged with chips that are not completely removed from the hole.

The cutter makes ideal holes; when removed, the drill leaves small chips along the edge of the holes, which in this case is not critical, since the screw head will close them.

Euro screws provide more secure connections than other types of fasteners due to the wide protruding thread that cuts firmly into the material.

Confirmates are installed using a screwdriver or drill with the appropriate bits or hand keys.

It is better for beginners to install manually in order to control the process, and in case of excessive resistance of the screw during installation, remove the fasteners in time, preventing mechanical damage to the material.

And that's all.

See you in the next articles.

Chipboard, from which almost all cabinet furniture is made, is fragile. Everyone knows how inconvenient it is to transport Soviet furniture. It must either be completely disassembled or assembled condition move very carefully, as the screws can simply be pulled out of their seats even under light loads. This is explained very simply. The design of the screw itself was impractical. The slots quickly licked off, preventing the assemblers from tightening the connection with high quality. A hammer came to the "help", with which they finished off the screw, breaking the channel, cut into threads. Modern elements joints of joints, which include furniture confirms, are devoid of these shortcomings.

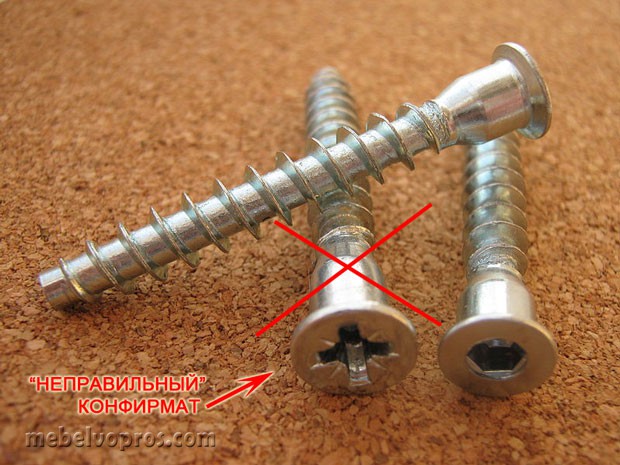

What is a confirmation, what does it serve

Confirmat is the same screw, which has its own design features. The body of the screw is more massive, made of steel High Quality coated against corrosion. The brand of material allows the screed not to break during twisting and under bending loads. Self-tapping thread with a wide pitch. The hat has secret construction, and the head of the screw is elongated. Slots for the tool come in two versions - for a curly screwdriver and a hex key. There is no usual sharpening at the end, it is blunt. There are modifications of Euroscrews, in which the cap has a cutting surface.

A single-element screed (confirmate) is suitable for joining wood blanks, boards made from wood waste (OSB, chipboard, as well as fiberboard, MDF), and plywood. In addition to connecting the elements, the euroscrew performs a frame-forming function, because it replaces the traditional corner, withstanding all bending loads. Furniture confirmations are supplemented with special plastic plugs. They mask the visible part of the hat under the color of the furniture.

Confirmat: dimensions

As mentioned above, confirmations come with different types slots. Euro screws are covered with galvanization, nickel or brass.

The sizing range is shown below. The first number indicates the diameter and the second indicates the length of the screw body. Designations are expressed in millimeters: 5.00 x 40.00; 5.00 x 50.00; 6.30 x 40.00; 6.30 x 50.00; 7.00 x 40.00; 7.00 x 50.00; 7.00 x 60.00; 7.00 x 70.00. The main, widely used size is confirmat 7x50.

What is the advantage of connecting parts using a confirmat

Confirmat sizes are different. It's relatively inexpensive fastener which has a number of advantages:

- allows you to quickly and reliably connect parts;

- does not require special skills in work and complex auxiliary devices;

- delicate to the material - does not destroy it;

- capable of withstanding tensile and bending loads;

- cabinet furniture at confirmats can be assembled and disassembled without destroying the seats.

Confirmate application technology

It should be said that under the confirmation the hole sizes are different. They must be drilled with three different diameters - under the thread, under the head and under the sweat. Therefore, there are two technologies for creating holes:

- In the first case, you can use a regular drill, but you have to take three different diameters. First you need to drill the entire length of the tie for the thread, then a slightly larger diameter for the head and, finally, for the flange of the cap. The diameter of each drill, of course, depends on the size of a particular confirmation. This method is inconvenient and time consuming, although it may be suitable for small amounts of work.

- The second option is more professional and adopted by qualified people. There is a special drill for confirmation with a step-type cutter. Such a tool simultaneously drills all the holes and makes a selection for the sweat. Application Required electric drill in high speed mode.

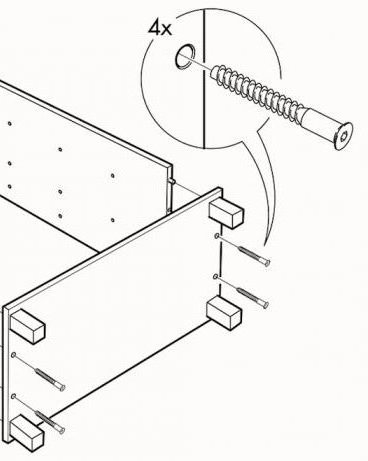

Euro screws connect parts at an angle of 90 degrees. In order to make a joint, it is necessary to fasten two parts together with the help of the way they should be connected according to the diagram. Then you should drill a hole for the confirmation screw through the plane of one part into the end of the other. Next, you need to screw the screed with a screwdriver. Here is the connection and done.

when working with euro screws

Despite the simplicity of fasteners, you still need to know a few tricks in working with a confirmat. This will help to avoid such unpleasant situations when the connected parts are displaced from the desired joint position. Sometimes the defect is not serious negative consequences, except, of course, the aesthetic appearance of the product. But it happens that these oversights lead to the complexity of functioning, for example, overwrite drawers, cracks appear, some details do not enter the openings. That's why:

- Having drilled a channel using a confirmatory drill, there is no need to rush to immediately screw the screw completely. At the moment when the head is about to enter the hole, it is necessary to clearly fix the parts in the desired position and, holding them, tighten the tie to the end.

- If the plate material is loose, for reliability it is worth treating the screw thread with glue.

- When assembling block structures, do not rigidly fix side walls until the free movement of all drawers has been verified.

Conclusion

For those who only want to learn how to assemble furniture with their own hands, perfect option mastering this matter - apply confirmation. The dimensions here must be maintained as accurately as possible. In order for the ends of the parts to be joined to be even, it is necessary to have an exclusively right angle with respect to the plane. Then the assembly of furniture with euro screws will simply delight and captivate.

We put marks on the flat side of the part, for subsequent drilling of holes for confirmation. If you still don't know how to do this, then you.

Step 2

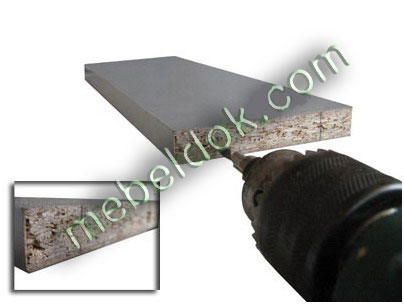

So, the marking on the flat side of the part is ready. We proceed to drilling holes for confirmation. To do this, you will need a drill and, or two conventional drills: one with a diameter of 5mm, the other with a diameter of 8mm (for countersinking a hole). If you are using a confirmation drill, it is enough to lay the part flat side down on some surface, so that the part that we will drill hangs from this surface. It remains only to drill a through hole according to the markings we have applied. If you use two drills. Then first drill a through hole with a 5mm drill, and then do a countersink to a depth of no more than 2mm with an 8mm drill.

Step 3

Then you need to mark up the end of the other part. How to do it correctly is written.

Step 4

We drill a hole in the end part of the part. There is nothing difficult in this. We take a confirmed drill or a regular drill with a diameter of 5mm and drill a hole to a depth of at least 40mm. From the end of the part, we do not make a countersink for the confirmer's hat.

Nuances:

- When drilling holes on the flat side of the part, do not press too hard on the drill, otherwise, when exiting from the opposite side of the part, the drill may chip the laminate around the hole.

- The worse the drill is sharpened, the more likely it is to chip off the laminate.

- When drilling a hole from the end of a part, make sure that the drill is pointed at the center of the part, and not "looking" up or down. That is, you need to drill strictly in the center of the part, do not tilt or raise the drill relative to the part. Otherwise, if you drill the hole at an angle, the drill may come out of the flat side of the part and ruin your workpiece.

Confirmate, he is euroscrew, he is euroscrew, he is screw tie- it is, simply put, a furniture screw. Favorite by furniture makers for ease of installation and does not require special precision when adding - you only need a drill and a hex key for confirmation.

To install this screed, two holes are needed: one is drilled at the end the main part, and the other - in the face part that is attached to the main one. Confirmate is so easy to add that you can even drill holes for it in place during the assembly process of the product. A novice furniture maker will also cope with this.

In order to simplify the drilling of holes for the euro screw, a special drill is available. consists of a cutter and a conventional drill. The cutter is designed for drilling a hole with a diameter of 7 mm (under the neck of the confirmation) and countersinking (under the head of the confirm). The drill is inserted into the skirt of the cutter and clamped with a screw.

It is often not so easy to find such a drill on sale, especially in small towns. But even if you do not buy it, do not be discouraged, it has some drawbacks. This is my personal opinion.

The first thing I encountered when working with a confirmation drill was that with a large amount of work, sawdust clogs between the drill and the skirt of the cutter over time. This quickly leads to the unusability of the drill. Vibration loosens the clamping screw. You have to clamp it more often, so the edges on the key and, as a result, on the screw itself are licked off.

I don't use a confirmation drill. I use two conventional drills ( different sizes under the thread and neck of the screw) and countersink.

Important nuance:

When drilling a blind hole into the end of the plate, it is important to maintain perpendicularity so that the drill does not pierce the wall of the part! I speak on my own.

But, I digress a little. An article about confirmation ....

The most popular confirmat is 7x50. The screw coupler is twisted with a special key by hand or with a hex bit using a drill or screwdriver.

In no case do not buy confirmations made for a Phillips screwdriver! With such a euro screw, you will not be able to tighten the parts as tightly as possible. This may lead to loosening of the product.

Confirmation cons:

- it is not a hidden fastener. You can see the hat. It is usually closed with either a plastic plug or a sticker, matching the color of the chipboard.

- furniture that is assembled on confirmations cannot withstand repeated assembly and disassembly (no more than three times). This is due to the fact that the confirmant cuts threads in chipboard - relatively soft material. And with frequent disassembly, the thread can break.

Confirmation advantages:

- confirmat is easy to install and does not require special equipment and accuracy when adding (as is the case with minifix). But you should not relax. To do quality furniture you need to precisely drill for any fastener.

- Confirmat pulls the details quite tightly and reliably. Well "sits" in the material.

- withstands heavy loads. But in the case of fastening a shelf, which is expected to be well "loaded", fasteners confirmat + dowel are used.

- can be corrected with a mallet. For example, align parts at the ends. But in this case, it’s better not to twist the confirmation from there.

In my opinion, Confirmat is convenient, reliable, and quick to use. But if the opportunity arises to use the equipment or fixture for more complex fasteners, I would choose an eccentric tie.

P.S. To help people who want to make high-quality furniture with their own hands, I am developing a chipboard fixture for drilling holes for a eccentric and hinge (). I hope to post it on the site soon.