High strength drywall. Which drywall is better to use for walls

Drywall - inexpensive construction material used in construction for the construction of walls, partitions and ceiling structures. To choose suitable look drywall, check out its main characteristics.

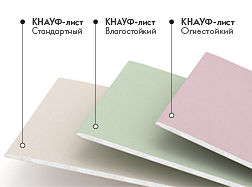

Varieties of drywall

Gypsum plasterboard (GKL) consists of a filler (mixture gypsum mortar- 93%) and outer layers of reinforcing cardboard (6%). Approximately 1% more is accounted for by absorbed moisture, the rest - by various additives. The material is light, easy to cut and install, and due to the addition of impurities and other components, it can acquire moisture-resistant and fire-resistant properties.

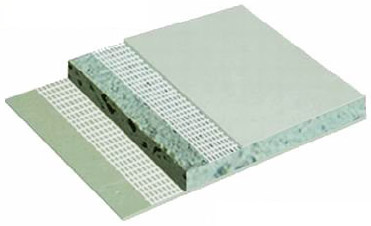

Gypsum fiber sheet (GVL) has a uniform structure throughout its thickness and does not contain a reinforcing cardboard shell. In addition to the gypsum component, it contains cellulose and various additives. The density of GVL is much higher than that of GKL, which is why its strength is also higher. Therefore, gypsum-fiber sheets are used where increased strength requirements are put forward for the material.

Gypsum fiber sheet (GFL) consists of a gypsum core and two layers of fiberglass, which provide it with high elasticity. On the back (rough) and front (smooth) sides, the fiberglass is protected by a 1 - 1.5 mm layer of gypsum. GFL sheets are produced with straight edges. The material is used in the manufacture of curved surfaces, such as columns and designer semi-circular ceilings. Also used as non-combustible wall cladding.

Thickness

Thin sheets of drywall (6.5 mm and 9.5 mm thick) are used in ceiling cladding, as well as creating ceiling structures, curved surfaces and arches. Sheets of medium thickness (12.5 mm) are used to level walls and create interior partitions.

Thick sheets are effective for arranging the base for the floor with the subsequent installation of any floor covering.

Edge

Plasterboard sheets with a straight edge (PC) do not require laying joints and are used for dry installation and to create multilayer structures. Thinned (slightly cut from front side) edge (UK) is used in combination with reinforcing tape and subsequent putty. Rounded (ZK) and semicircular (on the front side) edge (PLC) do not need a reinforcing tape, but require puttying. The transverse cut edge (FK) has an open gypsum core and is designed for filling joints without the use of reinforcing tape.

Properties of drywall sheets

Fire-resistant sheet (GKLO) is resistant to open flame due to the addition of special components to the composition. It is used for lining electrical panels, attics, ventilation shafts, industrial premises. Cardboard color - gray, marking color - red.

Moisture-resistant sheet (GKLV) incorporates silicone grains and components that inhibit the development of fungi and bacteria, and is also protected by an additional waterproof coating. It is used when finishing bathrooms, bathrooms and other rooms with high humidity. The surface is green, the marking color is blue.

Fire-moisture resistant sheet (GKLVO) combines the properties of the two types of drywall described above. Used for interior cladding high humidity and fire hazard, for example, workshops manufacturing enterprises. It has green color with red marker.

Reference article based on the expert opinion of the author.

The choice of material for leveling the walls of the room is enough difficult task even for a professional. Well, what then to say about a beginner whose questions are “Which is better - plywood or drywall?” or “What should be the optimal thickness of drywall for sheathing?” will inevitably lead to a dead end.

Below we will try to understand the intricacies of choosing a suitable type of plasterboard, and also consider the pros and cons of plasterboard sheathing in comparison with the use of other building materials.

Plasterboard for wall cladding

Varieties of GKL

Drywall is finishing material, which is based on a gypsum core, protected on both sides by multilayer cardboard.

Depending on the characteristics of the composition of these two elements, the following types of gypsum are distinguished:

- GKL- standard. This is used in rooms with normal humidity conditions.

It has low fire retardant characteristics, therefore it is not applicable in those rooms in which there is a risk of fire. The price of this material is the most affordable. - GKLV– waterproof. Suitable for leveling surfaces wet rooms, as well as where precipitation periodically falls on the walls or ceiling, for example, on loggias.

The cardboard layer is impregnated with a hydrophobic composition, due to which the drywall practically does not absorb moisture.

Note!

An additional plus GKLV is a fungicidal impregnation that protects the surface of the material and the gypsum core from fungal infections.

- GKLO– . Fiberglass reinforcement is introduced into the composition of the gypsum filler, and the cardboard is impregnated with flame retardants (substances that reduce flammability).

At the same time, even after the cardboard layer has burned out, the partition made of fire-resistant drywall due to fiberglass sintering retains its shape and prevents the spread of flame. - GKLVO- combined, combines moisture-proof and fire-retardant properties. The most expensive type of GKL.

The choice of drywall

For wall cladding, the so-called wall plasterboard is used, the thickness of which is 12.5 mm. There are also ceiling (9.5 mm) and arched (7.5 - 8 mm) varieties of material.

Both of these varieties can also be used to level the walls of the room, but only if the requirements for the mechanical strength of the sheathing are quite low.

Therefore, if you are looking for which drywall is best for partitions, then the right choice would be to abandon unnecessary savings and purchase full-fledged 12.5 mm panels.

But for the design of curved surfaces, such as arched niches in walls or window openings, it is better to use thinner drywall. It bends easier, and the load on the frame is less.

As for the answer to the question, “Which manufacturer of drywall is better to buy from?”, Here, most experts are unanimous. If the material does not have pronounced defects, such as a crumbled core or damaged cardboard, then the manufacturing company does not play a special role.

Of course, it is preferable to buy materials from well-known companies such as KNAUF or VOLMA, but GKL from a local low-capacity plant, as a rule, turns out to be no worse.

Pros and cons of drywall for wall cladding

Very often, as an alternative to leveling gypsum walls, it is suggested to use other materials, such as plywood, gypsum fiber boards, etc. Below we will consider all these alternatives, but in order to reasonably answer, for example, the question “Which is better - drywall or glass-magnesium sheet?” it is necessary to understand the pros and cons of the drywall itself.

Among the advantages of this material it is worth mentioning:

- low cost- sheathing and leveling gypsum board surfaces require significantly less financial costs than the use of other materials.

- Simplicity in work. Mounting drywall boards you can easily do it yourself, and you will not need any complex and expensive tools.

Note!

The site contains video tutorials on the use of drywall for solving various problems, as well as instructions for working with the main varieties of drywall.

- Possibility of further decorative finishes . After installing the GKL and on a leveled surface, you can glue wallpaper, apply plaster, and with high-quality alignment, even paint.

- Safety and non-toxic. Gyprock does not contain toxic substances and heavy metals in its composition, so its use in the interior is completely harmless to humans.

- High soundproofing characteristics.

However, there are also a few downsides:

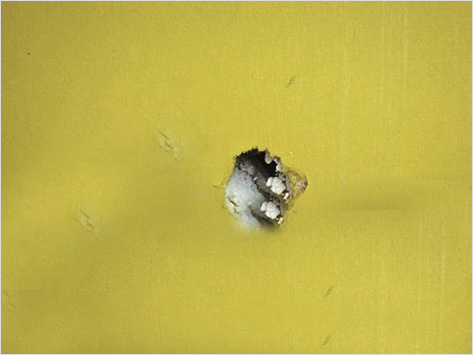

- Relatively low mechanical strength.

- Even GKLV is not able to withstand direct exposure to moisture for a long time. When wet, this material swells and deforms, and the surface sheathed with it has to be dismantled and restored.

- Without a decorative finish, the plasterboard sheathing looks unpresentable, so spending money on wallpaper, paint or decorative plaster still needed.

It is this combination of pros and cons that is typical for drywall. Now let's try to compare this material with the alternatives that the construction market offers us.

Drywall Alternatives for Wall Leveling

Gypsum fiber sheet

Gypsum fiber sheet (GVL) is a pressed gypsum panel reinforced with cellulose fiber. Sometimes GVL is used as an alternative to drywall, especially in rooms with high humidity.

When answering the question of which is better - drywall or GVL, the following arguments are given:

- Gypsum fiber has much less plasticity, therefore, for shaped structures, such as arches or curved niches, it is gypsum plaster that is most often used.

- Also, drywall is best used for partitions and finishing window and doorways, since GVL slabs here are quite difficult to mount with high quality.

- But for leveling vertical surfaces, especially in rooms with high humidity (bathroom, toilet, loggia), a gypsum fiber sheet is more suitable.

Simply put, it depends on the task before us which is better - drywall or gypsum fiber.

glass-magnesium sheet

Glass-magnesium building sheets (SML) are a finishing material based on magnesite binder. The basis of the sheet is fiberglass, and magnesite, magnesium chloride, perlite and other components are used as a filler. Appearance glass-magnesium sheets is shown in the photo.

Thanks to the spread of glass-magnesium sheets, discussions often arise, which is better - glass-magnesium sheet or drywall?

And here there are several points of view:

- On the one hand, LSU is significantly superior to drywall in terms of mechanical and moisture-proof characteristics. The structure of the glass-magnesium sheet is such that it can stay in water for more than 100 days without deformation, which makes it suitable for both indoor and outdoor exterior finish.

- On the other hand, glass-magnesium finishing panels they are quite expensive, and it is more difficult to process LSU than standard drywall.

Therefore, it is quite difficult to make an unambiguous choice in favor of one or another material. If you need high sheathing stability, then LSU should be chosen, but drywall is at least as good for most interior work.

Plywood and OSB

As a material for finishing the walls of rooms (especially in wooden houses) many suggest using plywood or oriented strand board - the so-called OSB.

When analyzing which is better - drywall or plywood, it is necessary, as in previous cases, to take into account the features of the room and the purposes for which we use the material:

- Both plywood and oriented strand board are made from natural wood raw materials. On the one hand, this provides them with a number of advantages, but on the other hand, it causes deformation of plywood boards.

- As for flexibility, here, too, the choice is in favor of drywall. The thing is that it bends relatively well only thin plywood, and thicker plates are almost impossible to bend without the risk of cracking. The same applies to OSB boards.

- Processing plywood panels is much more difficult than working with drywall. In addition, even with a slight error in size, the entire sheathing sheet will have to be changed. Giprok from this point of view is much more comfortable material.

- Do not forget also about the cost of plywood and OSB. Aligning walls using drywall will cost you much less than using wood panels.

If we analyze the construction market, there are still many alternatives to drywall, and therefore disputes like the discussion “Which is better - OSB or drywall?” Probably never stop. But it is worth taking into account that each finishing method has both pros and cons, and as for the ratio of price and quality, drywall is perhaps out of competition here!

Drywall is a sheet consisting of two layers, between which there is a base, special plaster. This material is universal, since it can be used for the construction of partitions, it is used to sheathe the ceiling and walls in any objects, both residential and non-residential. But there is a limitation - high humidity. Today we will talk about which drywall is better and what you should pay attention to when choosing it.

Pros and cons of drywall

But before that, you should dwell on the pros and cons of drywall. The advantages include:

- high level of sound insulation;

- the possibility of translating into reality the most daring ideas, for example, creating a structure round shape;

- the possibility of finishing by painting, plastering, laying tiles, wallpapering, etc.;

- safety for humans and domestic animals;

- affordable cost.

In turn, the disadvantages are:

- fragility and, as a result, the need for additional strengthening of the entire structure;

- not suitable for use in rooms with high humidity;

- when cutting, gypsum dust is formed, which can cause serious damage to the respiratory tract and eyes, so you need to wear a respirator and goggles.

Types of drywall

Now let's move on to talking about which drywall is better. In order to find the answer to this question, you need to get acquainted with the following classifications. Based on what drywall sheets are used for, this material happens:

- Ceiling. Used as a decorative finish, for example, multi-level suspended ceiling. Also, ceiling drywall perfectly hides communications. Distinctive features is an increased flexibility and the inability to withstand a significant load.

- Wall. The best option: quite flexible and at the same time durable, inexpensive. You can call it universal.

- Arched. Flexible and thin. From it, designs are created that imply the presence of curved lines. The disadvantage of arched drywall is the need for a double layer.

- Acoustic. The bottom line is soundproofing, so it is found in musical institutions, assembly halls and children's rooms. It has a porous structure and a perforated surface.

- Restoration. Placed on top of old drywall. Plastic.

- Laminated. The top is covered with polyvinyl chloride (PVC). Practically does not pass air and therefore is not recommended for residential buildings.

Drywall can be divided into groups such as:

- Standard (GKL). Suitable for rooms with low and normal humidity air, those where there are no special requirements for building and finishing materials.

- Fire resistant. Thanks to the reinforcing elements, it is not susceptible to fire.

- Moisture resistant. Suitable for rooms with high humidity, as it is treated with hydrophobic and antifungal agents.

- Fire and moisture resistant. Combines the properties of flame retardant and moisture resistant. Suitable for all rooms - with low, and with normal, and with high humidity.

In addition, the material we are considering differs in size, weight and edge. Let's dwell on them.

Size

The size of the drywall sheet is represented by three parameters:

- length: from 2 to 4 m;

- width: from 0.6 to 1.2 m;

- thickness: from 6 to 12.5 mm.

In this case, the length has a step of 50 cm. In other words, a drywall sheet can be 2, 2.5, 3, 3.5 and 4 m long. The most common is 3 meters. Waterproof drywall meets the parameters 2500/1200/12.5.

The minimum thickness of a drywall sheet, as mentioned earlier, is 6 mm. Preference should be given to material with an average value of 9.5 mm. The fact is that thinner drywall is only suitable for arches, and greater thickness will increase the load on the structure. Now you know what thickness drywall is best for walls.

Weight

The weight of a drywall sheet depends on the thickness:

- 6.5 mm - 5 kg;

- 9.5 mm - 7.5 kg;

- 12.5 mm - 9.5 kg.

Values are given based on 1 square. m.

Edge

In the vast majority of cases, the drywall sheet has even and smooth edges. But when thinking about which drywall to choose, remember that the edge can also be:

- straight- it is used when the so-called dry installation is carried out, which includes multi-layer sheathing;

- thinned on the front- requires puttying joints with laying reinforcing tape; laborious process;

- semicircular on the front- also, as in the above case, it is necessary to putty joints with reinforcing tape, however, in a smaller volume;

- refined and semicircular on the front side- puttying of joints is carried out according to the same technology as that of the semicircular on the front side;

- rounded on the front- two layers of putty are applied.

How to choose the right drywall?

The first thing you should pay attention to when choosing drywall is the goal. And only after that, select sheets by size, weight and edge. So, before heading to the store, answer questions such as:

- What is drywall for?

- what size, weight and with what type of edge;

- price.

Write everything down on a piece of paper. If you are not a specialist in construction and repair, then remember that:

- cardboard should not peel off, even at the corners;

- during transportation, drywall must be securely fixed, otherwise it may break;

- thickness depends on such criteria as the purpose, type of object and features of its operation.

Drywall Uses: Main Areas

In order to simply level the surface in a room with low or normal air humidity, ordinary (GKL) drywall is suitable. If this work will be done in a bathroom or any other room with high humidity, then moisture-resistant drywall should be chosen. For the kitchen, fire-resistant drywall is best suited.

For decoration production areas fire-resistant drywall must be used.

Drywall installation rules

Drywall for walls is one of the most common ways to level surfaces, regardless of their type. The main thing that is necessary in order for it to hold well is to buy a material of high quality and suitable in thickness and follow all the rules during installation. How to avoid mistakes when choosing drywall, and how to choose the thickness, has already been mentioned earlier. Now let's move on to installing it.

Two technologies are most popular: frameless and frame. The first involves the use of glue. This process can be divided into several stages:

- Surface preparation. She is cleared of old finish, is checked using special tool- level, treated with a primer. The primer ensures reliable contact of the skin with the adhesive.

- Laying the surface with ordinary (GKL) drywall. In addition to glue, putty can be used on plaster base. Everything is simple here: apply the substance to the surface, evenly distribute and mount the sheets to the wall. Optimal Thickness drywall at frameless technology- 12.5 mm.

The main advantage of frameless technology over frame technology is lower cost. The second technology is more common, as it allows not only to hide any irregularities, but also to lay engineering Communication. The crate can be made of either wood or galvanized steel. Galvanized steel is preferable - it is stronger and it is impossible to damage it when mounting it.

Ordinary (GKL) drywall sheets on a galvanized steel frame are installed in this way:

We make marks for the guides on the floor and ceiling. We mark the previously cleaned surface. The scheme includes vertical lines rack profile with marks for hangers. The first fastening should be located at a distance of 200 mm from the corner, and the rest after 600 mm from each other.

We fasten the elements of the guide profile through 500 mm from each other by means of dowels. In accordance with the marks, we install suspensions and attach racks to them. We put the ends of the rack profile into the guide and fix it with self-tapping screws.

We sheathe the frame with drywall. The head of the self-tapping screw should be immersed in the sheet by about 0.1 - 0.2 mm.

Both with frameless technology and with frame technology, it is necessary to process the seams and the surface with putty.

Now you know how to choose drywall and how to use it. We hope you do right choice and you will be satisfied with the result of your work.