How to make an electric kettle directly. How to repair an electric kettle at home.

Although now it's pretty big choice household electrical appliances Do-it-yourself electric kettle repair can be useful for those who have temporary financial difficulties or old kettle very convenient for you, you are used to it. It may also be that someone asked you to fix the device, or you are just an inquisitive person and you want to do everything yourself.

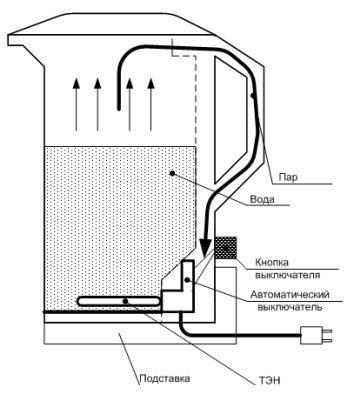

The principle of operation of the electric kettle

The principle of operation of an electric kettle is quite simple, and its device, even in expensive models, is not original. The heating element in the lower part, when electricity is supplied, heats the water. The heating element is connected to a thermostat (bimetallic plates), and as soon as the temperature reaches the set value, the kettle is disconnected from the network.

For ease of use, I include an LED light bulb with a load in the external circuit of the circuit. When the circuit is closed, the light is on, otherwise it is not. The electric heating device must necessarily include a thermal fuse that opens the circuit when overheated. It is needed in case you, for example, forgot to pour water into the kettle.

As seen, circuit diagram an electric kettle is similar to an iron circuit, and is not very complicated in itself. In fact, there are quite a few parts in the device that can break. The most difficult part is the thermostat, the device of which depends on the specific model. But in the event of a breakdown, they do not repair it, but change it to a new one.

Repair sequence

- If the electric kettle is broken, then first you need to check the cord with the stand, making sure that the voltage is supplied to the kettle. Do this by ringing the contacts with a multimeter. Try to disassemble the burned-out stand and solder the contacts, but if the contact group has melted, then it will not be possible to repair it.

- If everything is in order with the cord and stand, then the next step is to check the ring contacts on the kettle itself, after pressing the on button. Most likely, there will be no signal, so you need to unscrew the bottom part and check all the contacts already inside to find out what specifically does not work. A non-working coil or temperature sensor must be replaced.

- Next, check the automatic shutdown button located on the handle. It quite often fails because the contacts are oxidized. They must be cleaned with sandpaper, and the device will work normally.

In a modern kettle, the device is such that it is most difficult to get to the on-off button in order to fix it. To do this, you will have to remove the cover and unscrew the bolts at the top and bottom of the handle. This must be done carefully, as plastic parts break easily. If the LED bulb does not glow, then it is also changed.

Can a kettle be repaired if it's leaking?

Many are interested in the question of what to do if Electric kettle drip. Throw it away or can it be repaired? The cause of the leak may be a cracked housing or a worn seal. In the first case, it is best to go shopping for a new kettle, and in the second case, you can try to fix it by replacing sealing ring on ten. Glue the place of leakage in the area of the measuring scale, using various sealants, doesn't make sense.

If just a little drip new kettle, you can wait a while (a week or two). It is possible that scale is formed, which will tighten the microcracks. A kettle whose warranty has not yet ended and has leaked should be taken to a service center.

In order to keep the electric kettle from dripping for as long as possible, it is advised to descale it regularly, and if possible use soft, filtered water. In this case, the heating element will work better, and the sealing rubber will last longer.

Premature Shutdown

It happens that the kettle turns off ahead of time - it has not yet boiled, but has already turned off. In this case, it makes no sense to disassemble the device completely. You just need to clean the scale. You can do this, as you probably know, with citric acid. A small bag of lemons is dissolved in half a liter of water and the kettle is turned on with an open lid. If necessary, the procedure can be repeated.

Electric kettles have entered our lives for a relatively long time. Thirty years ago, a domestic manufacturer made them, both in the form of old samovars and ordinary teapots only with a heating element (heater).

Now there are a lot of these devices. They come in both metal and glass, ceramic and plastic. In addition, they have a decorative LED lights and other automation that protects the kettle from overheating, lack of water, and so on.

What is the difference between modern teapots and appliances from the times of the USSR? Basically - it's quality and power. In pursuit of cheaper goods, Chinese manufacturers do not pay much attention to both the quality of the case and the heater with additional “stuffing”.

But on the other hand, the power of the heating elements of these devices significantly exceeds their domestic "ancestors" at times.

For example, the standard power of a Soviet kettle was 800 - 1000 watts. Now this power has been increased to an average of 2500 watts. Yes, the second boils faster, but due to the quality of the materials and significant overheating, its service life is rather short. In addition, such power is simply deadly for the old aluminum wiring, and the outlet itself, no matter what it is.

Not surprisingly, the breakdown of such "wonderful" teapots is a common thing.

This article will focus on two issues that arise when you want to repair a kettle with your own hands:

- How to take it apart.

- What is one of the most common breakdowns of this device.

The first question arises with almost all modern electrical appliances, since manufacturers very carefully hide the location of the screws and sometimes it is simply impossible to understand where to start disassembling.

The photo shows one of the representatives of modern teapots of the middle price category. The principle of disassembly for all his brothers is almost the same.

So, remove the kettle from the stand and unscrew the screws from the bottom - as in the photo.

Here you can see two mounting screws. We also twist them.

Attention! Before proceeding with the disassembly of the kettle itself, check the integrity of the power cord and contacts on the stand.

This will not be difficult to do. It is enough to have some kind of "dialing" or a multimeter.

We connect the device to the socket pins, and with a piece of wire we “close” the contacts on the stand socket. If the measuring device responds and the contacts are in good condition, then the problem is still in the kettle.

We hold the cover of the handle with our fingers and carefully remove it, with an upward force.

When this part with the top cover is removed, dismantle the glass case.

Gently shaking it, pull it up. He should withdraw without resistance.

If this does not happen, check that all the screws from the bottom are unscrewed. You may have missed one.

In any case, you should not make great efforts, since it will not be difficult to break the plastic parts of the device.

Now the glass bowl is in your hands, what to do next?

Call the heater itself. To do this, connect the ends of the dialer to the leads of the heating element.

If the device reacts - glows or makes a sound - then the heater is intact.

Attention! Ring the heater should also be on the body. To do this, we connect one end of the dialing to the conclusions of the heating element, and the other to its metal case. If there is a clear "breakdown", such a kettle cannot be used!

We examine the side contacts. When the "ON" button is turned on, these two contacts should close. In the case of this kettle, one contact burned out and does not connect.

The problem has been identified. Now it is enough to clean the burnt contact and bend it so that it closes. For the convenience of doing this, the side plastic bumpers were removed with wire cutters.

Such a procedure will not affect the quality of the kettle, but it will be easier to get to the desired contact.

After you have made sure that the contacts are visually clean and closed, we check the connection with the device.

To do this, we put the lower part of the kettle on the stand so that the socket “sits” into the socket, and we connect the dial to the plug of the electrical appliance.

When the lever is turned to the “heating” position, the indicator measuring device should glow or somehow react, depending on what you are using.

Turning off the lever - the signal should disappear. If the first did not happen, then the contacts do not close. Repeat the procedure for cleaning and bending the contact.

Attention! Perform all manipulations with the stand disconnected from the network.

When the result is achieved, we assemble the kettle in the reverse order. Do not overtighten the screws to avoid accidentally stripping the plastic threads.

Here is the teapot assembled.

You can pour water into it and turn it on.

The photo shows that this repair method was successful, as evidenced by boiling water.

How long the kettle will work after such a repair is unknown, it all depends on the state of the contacts: the level of overheating, the thickness of the metal on which these contacts are installed. If you're lucky, it will serve you faithfully for more than one month.

Today it is almost impossible to find an apartment where the kitchen is missing. An electric kettle is a simple household electrical appliance for heating water. In this article, we will look at it device. This may be useful for you to repair it, because, like any appliance, kettles sometimes break.

working principle and circuit diagram electric kettle

To understand the principle of operation of any electrical appliance, its electrical circuit helps, which shows what goes where and how it happens.

The kettle works as follows. Through voltage (current) with a flexible cord is supplied to the contacts of the stand. The base of the kettle has its own contacts, which are connected to the contacts on the stand. Next, the current goes through a thermal switch, which is turned on with a key on the kettle and turns off automatically when the water in the kettle boils. The thermal protection switch is not directly involved in the operation of the electric kettle, it is always on and only works if the kettle is turned on without water. From the switches, the current flows tubular electric heater- TEN. The LED light is needed to indicate the on state of the device.

Electric kettle device

Electric kettle stand

In its design, the stand has three electrical contacts - two spring-loaded in concentric grooves and one in the center. The central contact (under the pin) is a connection to the grounding conductor PE. The other two (copper plates) supply voltage to the kettle (220 V).

Heating element (TEN)

If you remove the lid of the electric kettle, then at its bottom we will see. It is either open (curved heating element) or closed (metal disc).

At the ends heating element there are outputs isolated from the body by ceramics for supplying voltage. Steel flat contacts are welded to them by resistance welding, on which cap terminals are put on.

Switching on and protecting the kettle

To supply voltage to the heating element (turning on the kettle) in the handle of the device, there is an opening and closing contact.

To protect the kettle from overloads in the network, a thermal relay is installed in it. It is most often combined with a switch located in the handle of an electrical appliance. Relay disconnects voltage in case of short circuit, power surges and heating electrical wires.

To protect the kettle from overloads in the network, a thermal relay is installed in it. It is most often combined with a switch located in the handle of an electrical appliance. Relay disconnects voltage in case of short circuit, power surges and heating electrical wires.

Also, to protect the electric kettle, a thermostat is installed in it. It is located, as a rule, next to the heating element. His task is to turn off the device in case of excessive heating - they forgot to pour water into the kettle or it boiled away. The thermostat is a bimetallic plate that bends when heated, which leads to opening of the contacts. As soon as the plate cools down, it closes the contacts again.

Kettle on indicator

In most models of kettles, an on-state indicator is installed at the base or on the power button. This is most often an LED light bulb, the voltage on one contact of which is supplied through the kettle switch. Those. we turn on the device - it lights up, the device is turned off - the light is off.

This is with regard to the electrical component of the design of the electric kettle. Now let's talk a little about its other elements.

Appliance housing

The body of an electric kettle can be made of plastic, glass or metal. Cheaper ones are made of plastic, more expensive models are made of glass.

The stand of the appliance is usually made of the same material as the kettle itself.

teapot flask

In simpler and cheaper models, the body of the electric kettle itself serves as a flask for water. In more "advanced" ones, in addition to the body, there is also a flask (metal or glass). It is located inside the body, but does not touch it, thereby providing a space between the flask and the body. This space provides high temperature water long time. Those. The kettle is also a thermos.

The electric kettle has become an indispensable attribute of any kitchen and is the bestseller in comparison with the other household appliances. This appliance is widely used both at home, in the kitchen and in the office. But unfortunately, like any electrical appliance, the kettle fails after a while of operation. Since the price of this water heater is not too high, it is easier to buy a new one than to repair it. But if you consider yourself a home master, or a device for boiling water is dear to you as a memory, you can try to repair the electric kettle with your own hands.

The electric kettle works well enough simple principle, regardless of whether it is an expensive model or a budget one. At the bottom of the device is a heating element connected to a thermostat, consisting of bimetal plate. A tubular heater, when an electric current is applied to it, heats the liquid to a boil. When steam is formed during the boiling process, it passes through a special channel to the thermostat, as a result of which the latter turns off the power supply.

If you look at the scheme of operation of the device, you can see that it works on the principle of an iron, and does not differ in the complexity of the design. But before you repair the electric kettle, there are always difficulties with case disassembly, since different models latch units (holding the handle) are located differently, in addition, the fixing screws can be with a cap for a special screwdriver.

Typical malfunctions

The electric kettle is simple device, which contains few elements that can fail. However, there are still common problems, among which are the following:

- slow heating of the liquid;

- the device turns off prematurely;

- the kettle does not turn off;

- the device does not turn on;

- burnout of the heating element;

- water is leaking from the body.

Slow heating of the liquid

If you notice that the kettle does not heat water quickly, then pay attention to the condition of the heating element. thick layer scale on it, formed due to insufficient good service unit, has poor thermal conductivity, which takes longer to heat water. If the scale is not removed, the heating element may burn out.

In addition, the entire contact group of the device suffers from overheating, as a result of which the contacts melt or burn.

To get rid of scale, you can use the usual citric acid sold in shops. It is enough to pour 1-2 sachets of citric acid (20 grams each) into the tank, bring it to a boil and leave the heated solution in the tank for 30 minutes. After that, the container must be thoroughly rinsed with running water to remove scale residues. If necessary, the procedure can be repeated.

Device turns off prematurely

Such behavior electric water heater due to the fact that the shutdown of the device may be due to scale formed on the heating element. Since the heater has a fuse against overheating, it works and breaks electrical network. To eliminate the malfunction, it is necessary to descale the heaters.

Kettle won't turn off

During the boiling of water in the tank of the apparatus, the steam must be collected under the lid and sent through a special channel to the thermostat. If the lid is not closed tightly, then this does not happen, and the appliance will work without shutting down. If everything is in order with the lid, check that the steam hole, which is located on the side of the handle, is not contaminated with scale. In the case when everything is in order with the hole, it can be assumed that the kettle does not turn off due to thermostat breakdowns.

The thermostat at the electric kettle is located at the bottom of the case, and in order to get to it for replacement, you will have to disassemble the device completely.

For example, a conventional budget device was taken, which does not differ in design from more expensive models- electric kettle Vitek, Tefal, Polaris, Scarlett and others. By the way, in this model, as well as in the Vitek VT-7009(TR) device, the container is made of heat resistant glass. So, let's analyze the unit according to the following algorithm.

But how to disassemble the Bosch kettle, if when unscrewing all the screws on the bottom, it is not removed? Those who disassembled such a device encountered difficulties that often ended in a breakdown of the device. Since the process is quite difficult to describe, it is better to watch a video on this topic.

The device does not turn on

The reasons why your boiler does not turn on can be different.

- Faulty electrical cord and plug. To do this, you will need to “ring out” the cord using the tester, touching the probes to the plug contacts and the contacts on the stand (base). If a break is found, replace the cord with a new one.

- Bad contact in the stand(base). From long work Contacts can burn, because of which their conductivity is disturbed. If burns have formed on the contacts, they can be cleaned using a fine sandpaper. But in the case when they are melted, they will need to be completely replaced.

- Faulty internal switch in the device. Since the switch has to experience fairly large loads (from 1500 to 2000 W), its contacts may melt over time. This may cause the machine to not work. The switch is located at the bottom of the handle, and in the event of a malfunction, it looks as shown in the figure below.

In this case, the button must be replaced. But there is a button malfunction, in which you can fix the kettle with your own hands without replacing it. If you look at the button from the side, you can see 2 contacts that close in the “on” position. If on them soot is formed, the device will not turn on.

To remove carbon deposits, you can use fine-grained sandpaper, a nail file, or a thin file. To make it more convenient to do the stripping, you will need a small “refinement” of the button, namely, removing the sides with the help of wire cutters.

Another reason that the device does not want to work can be called malfunction of the mechanical power button. This breakdown is most often found in the Tefal vitesse model, since plastic rails are built into the handle of the appliance, which transmit translational movement from the external button to the internal one located at the bottom of the unit.

After this part breaks, turning on the Tefal kettle becomes impossible. To understand in more detail how to repair an element that has broken, you can watch the video, which discusses one original way defect fixes.

Heating element burnout

When repairing electric kettles, both old models and newer ones, the most common failure is the burnout of the heating element. The problem with heating elements arises, first of all, due to their overheating due to untimely descaling.

Before repairing a kettle with a disc heater or a heating element in the form of a spiral, it is necessary to disassemble the unit in the manner described above. After that, take the tester and connect the probes of the device to the output contacts of the heater. If the lamp lights up on the device, or it makes a sound, then the heating element can be considered serviceable.

How to check the heating element if no measuring device? It turns out it's very simple. It is necessary to connect zero from the mains to one contact of the heater, and the phase to the other. Next, insert a 220 bulb into the socket from which 2 insulated wire. Touch one stripped end of the wire to one contact of the heater, and the other to the opposite. If the light is on, then the heating element is working.

If it turns out that the disk heater has burned out, then it cannot be replaced, since it is one with the bottom of the appliance, such as in the Scarlett kettle, or Vitek VT-7009 (TR). Therefore, you will have to buy a new unit. Only the heating element can be replaced open type.

water flowing

If you notice that water is flowing (leaking) from the reservoir of the device, then it is recommended to use such an apparatus for a while, until scale forms in the microcracks, which can block the leakage of liquid. If this does not help, then you will have to buy a new “boiler” if the warranty period has expired.

Another reason that the reservoir is leaking may be loose connection of the electric heater with the body of the device(if the heating element is open type). In this case, you can tighten the fasteners holding it. If this does not help, then you will have to remove the heating element and change the rubber sealing gasket which has worn out.

Thus, we can summarize: in some cases it is quite possible to repair a unit for boiling water on your own. But if you lack certain repair skills household appliances, then the best option will buy a new kettle. Repair in service center, from a financial point of view, does not justify itself, and there is no guarantee that the breakdown will not happen again.

Repairing an electric kettle is simple - everyone can handle it. Inside there is a spiral, rolled to the bottom, controlling the thermostat, with a button. The design is powered by a voltage of 230 volts, protected against overheating by a thermal fuse. More often wire - it is necessary to change. Cheap models lack the intricacies of protection.

Repairing an electric kettle with your own hands can sometimes be an interesting activity, especially if the lid plus the handle are molded, it is impossible to undock from the electric kettle. Cause: The screws are under the edge of the door. You think ... how the Chinese managed to assemble a miracle of technology. Haven't seen a table lamp yet.

Repair of electric kettles in China

The products of Guangdong province are widely known, they just forgot to warn the consumer that from there ... China is rich in economic and other interesting zones that give tax and some other concessions to manufacturers. The United States looks without enthusiasm at the conflict with the heirs of communism, whom Nietzsche predicted the fate of a couple of centuries ago. Today we will see how to repair a Chinese electric kettle made according to standard project for a company that does not seek to reveal the true origin, with a probability of 95% being a representative of Eastern Europe, mb, Russian Federation. Let's see what compatriots indulge in - the best examples of world household appliances pass through the hands of Guangdong workers.

China's GDP ranks second. Japan - the third. Not bad, given the state of the Land of the Rising Sun, which survived the Second world war. Feudal Japan became the world's largest electronics manufacturer.

Housing, side panel when repairing an electric kettle

Below are photos that allow you to personally enjoy the views of the part. the simplest design. There will be links to the pictures in the text. If you want - look, if you don't want - scroll blindly. Disassembly begins with a lid. If you skip a step, you can't take it off sidebar that hides the LED plus the switch. With the side panel on, it is more difficult to remove the bottom. Dilemma. Do the opposite, if you are looking for difficulties, then you can not remove the cover at all!

Lid. It is held by two ears with two pins. A plastic monolith, you are tormented to disassemble, installation is even more difficult. Pins perfectly shows the first photo. There are two screws on the sides, unscrew immediately, remove the side panel. Everything is neat inside - plus models, we often find a whole mess of wires. Let's go to the bottom.

Around the connector, where the ground terminal is provided (the structure is hanging in the air), there are three screws. We unscrew, we are convinced: the bottom is slow to be removed. Along the perimeter there are six plastic teeth included in the six holes in the body. So that it does not accidentally fall apart, wound by operation, there is a guide on the sides of each tooth. Alternately, the teeth will have to be snapped off with a screwdriver separately (see photo below), break it - you will break the bottom when removing it. We took a picture of each tooth, illustrating what was said. We put the dismantled parts aside, look at the switch.

Switch, temperature sensor: electric kettle repairman's point of view

The photo shows from the bottom position. A shiny circle with a cut - a mechanical sensor. Thanks to the bimetallic plate, having seized the moment, the electric kettle turns off. The water boils, an increased amount of steam begins to stand out. There is a small hole in the housing located under the switch, covered with a circular loose plastic plug (see photo). The plate is installed, being above the steam gate. Boiling begins, the temperature rises sharply. After a moment, you can hear a click. The tongue of the plate, made up of a pair of metals, sharply bends upwards. Looks like a bimetal relay.

Now the switch. Not so simple. The part is devoid of visible connections, except for the metal bracket shown in the photo on the side. The upper movable part is attached to it. When we turn on the kettle, the switch spout rests on the tongue of a round plate with a cutout, the bracket is compressed. Due to the design, indefinitely, the parts retain their initial position. Click! The slightest jerk releases the bracket, which returns the switch to its original position.

Let's look at the bottom of the case. Here are:

- circular connector;

- rolled spiral;

- LED divider resistor with a nominal value of 14 kOhm.

While the switch is dormant, the LED glows blue. A full voltage of 230 volts is applied. The photo available shows: the resistor burned out, the contacts were inserted into the clamping terminals, one could not stand the inspection. I had to solder. The divider resistor is connected in parallel with the rolled heater. The electric kettle turns on - the glow changes to orange. Dual LED ( school teachers silent?), in contrast to typical use both shades work simultaneously while the water boils. Addition of electromagnetic waves different shades gives orange. It is difficult to enumerate the shades that form the superposition (the repairman is deeply indifferent).

Remove the resistor, or it will burn out - nothing bad will happen. It's just that the LED will stop changing color, tracking changes in the position of the switch. Color is irrelevant to water temperature. It is easy to notice - there is no thermal fuse. We believe that there is simply no protection. Those who wish can equip the part with a metal case, next to the ring connector. Provide protection against empty inclusion. This kettle may cause a fire if unprotected. We recommend that the device be supplemented with a thermal fuse. Put not somewhere in the center, the perimeter of the heating element, increasing reliability.

The resistance of the heating element is 30 ohms. The photo shows through a fraction the power values on metal surface 220 and 240 V. Enough to understand what can break. The device of the electric kettle is simple, even the kettle can be repaired, but ... It was easy to remove the lid, but put it back! We hope readers will solve the question on their own, it is difficult to answer. But we will show you how to disassemble the switch for those who want to clean the contacts. The gap distance is scanty, steam is in the air. Just look at the two screws from the picture: they are covered with rust, although the electric kettle has not really been used.

We believe that six months later it will be necessary to refresh contacts. Let's take a look at the switch:

- Place your finger on the plastic ear that secures the switch to the housing.

- Press the button on the opposite side with your thumb.

- Squeeze your fingers gently, the retaining bracket will fly out. Guard more than the apple of your eye, otherwise the electric kettle will only have to be thrown away.

Assembly is carried out in reverse order. Hook the bracket with the front of the button, rest it on the base, gently put the part in place without any extra effort. The bimetallic plate can be easily removed with a knife or a screwdriver. Self repair electric kettles consists of such trifles, otherwise it will not take long to break the cover when putting it on! Contacts are made of bronze, visible in the photo. It is impossible to clean with alcohol, gasoline, there is plastic nearby. Guess we'll have to live acetic acid, the switch must wait out the night.

You have to disconnect the terminals. The Saturn model in question is not simple. The photo shows a small hole in the terminal, which corresponds to the spike of the second half. If you press there with an awl, the connection is disassembled without problems. Otherwise ... It is impossible to tear one from the other. The process is aggravated: the joints are protected by a heat-shrinkable cambric, which is very poorly heated with a hair dryer. It crumbles easily, barely holds on, but ... does not come off. Therefore, if necessary, cut, disassemble the assembly. Clamps are disposable. The resistor wire jumped out, it was not possible to compress it back, it is not convenient. I had to solder.

Weld the plastic with a soldering iron. Along the way, using the necessary additives (polyethylene). Choose material that is compatible with food industry. Glue use heat-resistant, harmless to humans.

Conclusion on the repair of an electric kettle

As readers understood, this is one of the cheap models of Chinese teapots, made by order of a certain company. Maintainability of the product is zero. Difficult to take apart, even harder to assemble. Picking, it is easy to spoil the presentation, functionality. The bottom dressed quite simply, with considerable effort, threatening clicks. The lid caused real problems. Having a hairdryer, being able to use it well - many troubles can be avoided. Having the same screwdriver, when disassembling it will be tight.

Even in the store we recommend to evaluate the assembly. How difficult it will be to disassemble the device in order to repair the electric kettle with your own hands. If the product is disposable, then this is not very good, and if it is also dangerous ... no comment.

We hope after this detailed review our readers will be able to repair both Tefal electric kettles and Scarlet electric kettle repairs. After all, the vast majority of products are made in China... We want to say goodbye, see the pictures, evaluate, study. If the bimetal plate is inserted with the wrong side, the electric kettle will stop turning off when it boils! Although the click is audible. Wrong steppe...

Main surprise

Boiled water causes allergic reactions. It is difficult to name the percentage of people prone to illness. Kashpirovsky classifies half of the planet as an exacerbated reaction. He treats almost 100% of those who applied. Some (arrogant) are sent back. Let them try local hospitals.

The regulation of the immune system is poorly understood by science. A sane person who knows Quincke's edema will beware of rejecting the slightest possibility of a cure.