How to install gas lifts on furniture. Installation of a gas lift

What should be the kitchen furniture? It would seem that the question is simple, and it is not difficult to answer it. Each person would note beauty, functionality and reliability. That's right, you can't argue with that.

But you know what usually goes unnoticed? For accessories. Of course, we select external fittings, that is, handles, according to the design of everything kitchen set everything needs to be in harmony. But do not forget about other types.

Beyond the façade lurks great amount various elements. For instance:

- Gas lifts for the kitchen;

- guides;

- hinges;

- Shelf holders;

- And other systems.

Without this, it is impossible to think that kitchen furniture will last a long time, and functionality will meet all the necessary standards and requirements.

That is, the need for high-quality fittings is an obvious fact. And if the price of the entire headset is compared, then twenty-five percent of the cost falls precisely on the cost of accessories. Unbelievable but true.

Lifting mechanisms for opening doors

What is a gas lift for the kitchen? This lifting mechanism belongs to the bracket category.

It is designed to open the upper tier of cabinets, the doors of which open up.

And although this opening option is not the main one, many manufacturing companies have recently begun to give preference to it.

The advantages of this mechanism are not few, but it is worth noting the main ones:

- Self-adjusting smooth running;

- Reliable fixation in the open position;

- Two types of opening - step-by-step (friction) and automatic;

- The fastening of gas lifts corresponds to the material from which the furniture itself is made. That is, from chipboard or aluminum.

- Possibility of opening the door without a handle. To do this, simply press on the surface of the door, and it will open by itself.

Gas lift design

- Valve.

- Sleeve.

- Piston.

- bypass valve.

- Friction type bearing.

- Stuffing box.

- Anther.

- Piston seal.

Gas lift design

Like any mechanism, a gas lift consists of several parts.

- The body, which is a sealed cylinder.

- Valve.

- Sleeve.

- A stem that moves freely inside the body.

- Piston.

- bypass valve.

- Friction type bearing.

- Stuffing box.

- Anther.

- Stuffing box packing that creates tightness of the structure.

- Piston seal.

Nitrogen is pumped inside the body, it is the working medium.

Note! The gas lift is a completely sealed design. Nitrogen is pumped into the cylinder during the manufacture of the mechanism. Therefore, this device cannot be repaired.

Do not even try to open it with your own hands. All internal system is under pressure.

Depressurization, which is resisted by glands and packings, can lead to the fact that the gas lift simply ceases to perform its functions.

In addition, you are not an expert, and the slightest penetration inside can cost you trouble.

Note! hermetically sealed arranged system may explode in your hands. So don't try to open it. This can be costly for you and those around you. The minimum is minor injuries and scratches, and it’s scary to talk about the maximum.

The working indicator, which is the main one, is the compressive force. Therefore, when choosing a gas lift, it is necessary to accurately determine the weight of the door that it will open and hold.

Accordingly, the heavier the door, the more effort is needed to hold it. So, the holding force should be greater.

There is another selection criterion, it depends on the length of the mechanism itself. Of course, this in turn depends on the size of the door being held.

Therefore, it takes into account the correspondence between the length of the gas lift and the thickness of its working cylinder. The longer the device, the thicker it is.

Surprisingly, this mechanism works in automatic mode (one of the types). When the door is opened, it activates after a certain time and starts the closing procedure.

This is useful in two cases:

- With the forgetfulness of the hostess.

- When the lockers are suspended very high, where the height of the person and the height of the placement of the furniture element do not correspond.

How to determine the force required to open the door

Currently, manufacturers offer mechanisms that can withstand loads of 60, 80, 100, 120 and 140 newtons.

It is generally believed that ten newtons of force will be sufficient for a load of one kilogram. Therefore, it is not difficult to calculate the load, and choose a gas lift according to it. By the way, in

You can find a calculator on the Internet that will accurately determine the ratio of load and holding force.

For safe use furniture shock absorber, it must be used with a lifting mechanism.

The service life can be affected by the installation of a gas lift in the structure.

Installation of furniture gas lift:

During installation, the stem should look down, and the sleeve, respectively, to the top. Installation is carried out only in the open position of the gas lift. The gas lift attachment points must be securely fastened with an eyelet using an appropriate bolt or with another attachment fitting, the gas lift attachments must be fixed to the connecting structural elements allowing the gas lift to move up and down. Fittings must operate freely. At long-term storage gas lift before installation, it must be borne in mind that the first cycles of operation may be with more force than nominal. It is necessary to check the performance and force (little or much) of the gas spring already in the bed structure along with the mattress, without a mattress, the frame may not hold in the closed position and rise if you squeeze the gas lift with a force of more than 200N by hand - it will not shrink, this is normal and should not , it is also not necessary to use a hammer and other objects, there is no need for any “breakdown” of the stem, install it in the structure with full weight.

Note: The gas spring must not be cut, heated or shocked, inside high pressure- it is dangerous.

A gas spring with a force of 300N or more must not be closed by hand, it will close already in full load in the structure.

Dismantling of furniture gas lift:

Gas lifts must be dismantled from their attachment points so that the cylinder (sleeve) is not damaged. Avoid compression and damage to gas lifts. Unscrew the fasteners and remove the gas lift from the mechanism only in the open position of the gas lift.

Gas lift rod:

Protect the surface from such external factors like dyes, scratches, bumps, dust and chemical factors.In the event of such an impact on the surface of the rod, it will lead to damage to the seals and may affect the performance and service life of the gas lift, if specified negative factors are present in the design where the gas lift will be used, then possible damage can be minimized by using an additional protective tube - a cover to protect the rod. Avoid bends and twists in the stem.

Gas lift cylinder:

The cylinder has a high pressure inside, it must not be damaged, heated, drilled or opened.

Compressed gas in a gas lift cylinder can cause volume expansion, which can be detrimental.

TECHNICAL INFORMATION

- Gas lifts can be compressed own strength(+30% per kg), (1kg = 9.81 Newton).

- The power of the gas lift must be selected according to the required weight, however, when choosing, the angle of rise must also be taken into account, because. force at different angles of elevation may vary.

- The temperature of the operating mode of the gas lift should be in the range: from -30 to +80 degrees Celsius. Fluctuations in temperature affect the power of the gas lift (approximately 3% of the rated power for a 10 degree change in temperature), as the temperature changes environment, the viscosity of the oil inside the gas lift also changes. At high temperatures internal seals are damaged.

- To obtain correct test results, the gas lift must be tested with a condition of no more than 6 cycles per minute, otherwise the stem gaskets will overheat and possibly be damaged.

- It is not recommended to open or close the gas lifts to the stop, as this may damage the internal parts.

- Maximum applicable pressure 160 bar (at 22 degrees Celsius)

- Max speed stroke of about 300 mm/s. If the speed is increased, it can cause overheating and damage the internal seals.

- Tolerances for deviations along the length of the gas lift: +/-2mm, for power: +/- 8%.

Store in its original packaging in a dry, ventilated and dust-free room at a temperature of -30 to +80 degrees Celsius. average temperature+22 degrees.

Storage of gas lifts in a warehouse for more than one year is not recommended. If the gas lift is stored long time and does not work, it may affect the opening speed, if the gas lift is started after a long period of inactivity, the opening or compression power will be momentarily higher than its rated power.

VARIETY OF GAS SPRINGS

There are varieties of gas springs in accordance with their purpose (application).

All types of gas springs have differences in length, force, fastenings (fittings) and diameters of the cylinder and rod.

Gas spring (gas lift) direct action- a standard gas spring, which is widely used in furniture (sofas, beds, facades) and cars (engine compartment, trunk) as well as many other structures.

Rest position - open position, works in compression.

Gas spring (gas lift) of reverse (linear) action- used in special equipment and industrial equipment. Rest position - in the closed position, works on unclenching.

Gas spring (gas lift) lockable- used in medical furniture and equipment, as well as in office chairs, bar stools. A distinctive feature from linear gas springs is the ability to stop at any position; for this, the gas lift on the stem (sometimes remote separately) has a stopper button. There is a simplified view of a lockable gas lift that has one or two fixation points along the compression / expansion path. There is also direct and reverse action (compressed and open rest positions).

Gas spring damper- used in medical technology and specialized equipment. This type gas lift is similar to a gas spring of linear action or blocked, but its distinguishing feature in that after the start of the movement there is a delay of 2-3 seconds before continuing the movement.

There are also vice versa - fast (sharp) movement of the rod (used mainly in the production of pneumatic weapons).

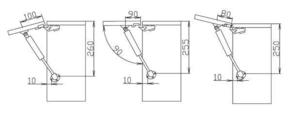

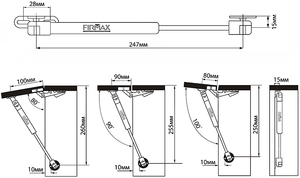

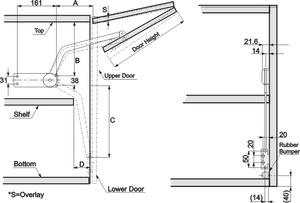

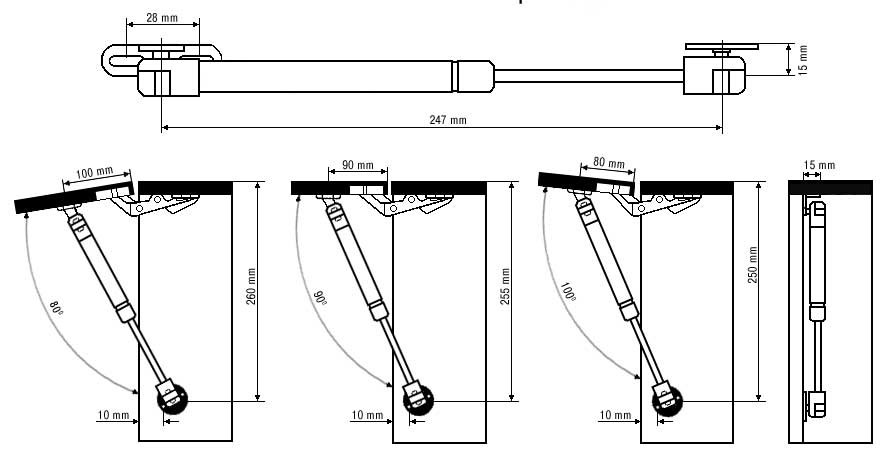

And finally got it right. In the example, I put Boyard gas lifts. Attached to them is such an additive scheme. It shows that three installation options are possible: at an angle of 80, 90 and 100 degrees. Personally, I prefer a right angle, so we will put elevators under it.

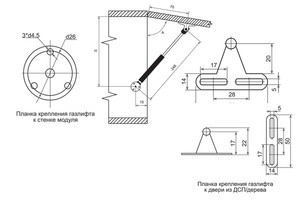

This is why we will dance. So, the installation of gas elevators begins with the marking of holes on the wall of the box. We fasten the mounting plate with three screws.

The size of 239 mm turned out if we take into account the thickness of the upper horizon, that is, 255 mm minus 16 mm.

The next stage is the addition of the response element to the facade. Everything starts again with calculations, and ends with a pair of self-tapping screws.

Please note that if the gas lift will be installed on, as in lower tier of this box, then on the wall it is necessary to set aside not 239 mm, but 245 mm, and on the facade not 90, but 95 mm.

We mark on the horizon of the box itself places for self-tapping screws that fasten the striker of the loop.

Hanging the facade. By the way, in this photo I noted the filler dimensions that need to be done for installation on semi-overlay hinges.

And then we just snap the gas lift onto the ball pins of both strikers. Often it comes in tight, so you can apply force.

Everything is ready. In the closed and open position, the elevators look like this:

A slight adjustment of the front angle is possible. It is produced by shifting back and forth (within the slot) of the striker on the facade.

Personally, in order to minimize the number of errors, as well as speed up the assembly process, I made this

Each cabinet has fastening connections in its design, which ensure their convenient operation. An important role in correct work gas lift plays on the kitchen cabinet. On condition correct installation With this device, you can not worry that at some point the furniture doors will warp or start to open spontaneously.

To keep kitchen furniture functional, it must be equipped with a gas lift. Moreover, even a non-professional can assemble and install this device on a kitchen cabinet. If you follow the installation instructions exactly, you can securely fasten doors that can be opened with a minimum of effort. It must be remembered that reliable performance kitchen cabinet depends not only on the correct installation of the gas lift, but also on its choice.

What is a kitchen gas lift?

Used in kitchen furniture, gas lifts have the form of a lifting mechanism, the main function of which is to hold and open cabinet doors. Thanks to the kitchen gas lift, the doors of the wall cabinets can be opened up without extra effort. The widespread use of this device in furniture production gained through the following benefits:

Used in kitchen furniture, gas lifts have the form of a lifting mechanism, the main function of which is to hold and open cabinet doors. Thanks to the kitchen gas lift, the doors of the wall cabinets can be opened up without extra effort. The widespread use of this device in furniture production gained through the following benefits:

- Reliable fixation open door in top position. Due to this, you can open several cabinets at once with one effort;

- Smooth opening of the door with the possibility of self-configuring the mechanism;

- Complete absence of noise during the operation of mechanisms;

- There is no need to install handles on the doors;

- The mechanism is activated by light pressure of the hand.

The operation of this device is based on a fairly simple principle, provided by the operation of a gas spring and a hydraulic shock absorber.

When the door is displaced by 10° relative to the initial position, the furniture gas lift mechanism is activated, which automatically opens the door to a working radius of 90°. The door operation control mechanism itself has a complex device and includes the following elements:

- cylindrical body;

- piston;

- sleeve;

- valve;

- stock;

- plain bearings;

- stuffing box;

- anther;

- seal.

Thanks to its thoughtful design, it supports full tightness of the cylinder, which, even in the manufacturer's workshops, is filled with nitrogen, which provides the required pressure at the moment of clamping. The device has a non-separable design, so it cannot be repaired.

The installation of a furniture gas lift begins with the preparation of a set of tools and markings for accurate fastening.

The installation of a furniture gas lift begins with the preparation of a set of tools and markings for accurate fastening.

Instruments

If necessary, you can install the gas lift yourself. But for this you will have to prepare a set of the following tools:

- screwdriver;

- screwdriver;

- pliers;

- hammer;

- electric drill;

- ruler;

- roulette.

Before installation work, it is necessary to mark the places for installing the gas lift mount.

Before installation work, it is necessary to mark the places for installing the gas lift mount.

Before installation, it is imperative to check the existing equipment for compliance with the design of the cabinet. So, if the inner cavity wall cabinet has a height of 365 mm, then a gas lift with a length of 355 mm is used for it.

For correct execution installation of the device, it is necessary to observe the order of cabinet layout:

First thing it is necessary to mark the center of fastening on the sidewall. To do this, you need to measure from inner surface top cover distance 366 mm. The same is done from the front edge of the sidewall, but here the indent should be 37 mm.

After that, a center mark is applied for mounting the device. It is necessary to mark a distance of 128 mm from the upper cut. From the side end, you need to count the indent, which should have a length corresponding to the height of the fastening on the side of the cabinet. Most often it is 19 mm. Similar operations must be performed on each side of the wall cabinet.

Installation process

When starting to install a gas lift, the first step is to fix the base of the device in the side of the cabinet in a pre-applied marking place. Usually two types of fasteners are used - with a spring and a plate. The bracket is mounted by screwing the sidewall into the tree at the mark, and the elevator head is installed by simply snapping it into the bracket.

When starting to install a gas lift, the first step is to fix the base of the device in the side of the cabinet in a pre-applied marking place. Usually two types of fasteners are used - with a spring and a plate. The bracket is mounted by screwing the sidewall into the tree at the mark, and the elevator head is installed by simply snapping it into the bracket.

For some devices, the base is made in the form of a plate with a hole. In this case, it is installed on 3 or 4 screws in the side part so that the center of the hole corresponds to the marked mark. Next, you need to place the hinged head of the elevator into this hole and fix it. Particular attention must be paid to ensure that the base plate does not show signs of deformation. Otherwise, the damaged elevator will not work properly.

In the same way, the device is mounted on the inner surface of the door. Particular attention must be paid ensure that the required angle of inclination of the hinge is maintained, which should be approximately 8 °.

To make sure that the direction is correct, proceed as follows: it is necessary to move the stem to the maximum extended position.

A similar installation technique is used to mount the gas lift on both sides of the cabinet.

In order not to have problems during the operation of the kitchen cabinet, the following recommendations must be observed during the installation process:

In order not to have problems during the operation of the kitchen cabinet, the following recommendations must be observed during the installation process:

- Mounting the device in must be done on both sides. This will help prevent distortion.

- The door must be fixed to the top cover of the cabinet using furniture hinges dish type.

- Particular attention should be paid to the type of device used. If the fastening device has a load of more than 80 N, then it must be remembered that it is only suitable for installation on heavy doors. For a cabinet of a different design, they should not be used due to increased rigidity.

- The gas lift must be installed only after all the necessary fittings, cladding and decor elements have been installed on the door.

- Before proceeding with the installation of the gas lift, remove cabinet from wall.

- Sometimes the opening angle of the door is insufficient. In this case, the problem is solved by moving the gas lift installation point closer to the front cut of the sidewall.

- To avoid quick failure of the mounting device, it must be installed exactly following the installation instructions.

The choice of gas lift for the cabinet

When choosing this fixture for kitchen furniture, you need to pay attention to the following parameters:

When choosing this fixture for kitchen furniture, you need to pay attention to the following parameters:

- device dimensions;

- pressure force of the gas spring.

Before buying a gas lift for furniture, you need to make sure that it matches the dimensions of the kitchen furniture. To do this, before going to the store, measurements of the height of the door and the depth of the cabinet are performed. Based on the obtained values of the characteristics, a decision is made in favor of the acquisition suitable model gas lift.

Most often in stores, these devices are offered in three sizes in the extended state - 164, 244 and 355 mm. Yet it is necessary to pay attention to the length of the gas lift in a compressed state and the maximum extension length of the rod.

Proper operation of the fastening device depends on the pressing force. This characteristic is normalized, the value of which must be indicated in the passport for the product and on the body of the device. In order not to make a mistake with the choice of gas lift, you need to know exact weight doors, taking into account fittings, coating and decorating elements. Typically a fastening device for kitchen cabinets designed for a force of 60, 80, 100, 120 and 140 N. To select the most suitable gas lift model, you must follow the rule: for 1 kg of door weight, there must be a force equal to 10 N.

Conclusion

The operation of the kitchen cabinet largely depends on the quality of the installation of such a mounting device as a gas lift. This device is very often used in furniture production, providing a comfortable and simple operation furniture. Gas lifts are also used in kitchen cabinets. But at the same time, gas lifts, like any fastening device, can fail at some point. For this to happen as soon as possible, very carefully approach the installation process of this device. For this, it is important not only to know the design of the gas lift, but also the rules for its installation on the doors of kitchen cabinets.

When repair work in the kitchen are completed, you can proceed to the most pleasant process - the selection and purchase of furniture. Any hostess wants to be surrounded by a functional and comfortable atmosphere. All interior items should not only be beautiful, they are subject to requirements for the strength and durability of facade coatings. When studying market offers, it is necessary to carefully consider specifications accessories. The gas lift for the kitchen facilitates the process of cooking, the durability of the operation of the entire set depends on the degree of its reliability.

The importance of kitchen fittings

Fittings in the kitchen space are of paramount importance, because the hostess should always have everything “at hand” and access to these things is often necessary as quickly as possible. Under the fittings of a kitchen set are understood various structural elements furniture: shelf holders, gas lifts, handles, hinges and other elements, without which the operation of cabinets and bedside tables would be difficult.

Experts say that about 22-25% of the cost of furniture in the kitchen falls on fittings. This explains the increased requirements for its strength and durability, because you have to pay for 1/4 of the entire situation.

Modern Dining Rooms Demand modern elements, as well as .

The main characteristics of the gas lift

The key representative of kitchen fittings is a gas lift, the principle of operation resembling lifting equipment (crane). The category of this item is bracket.

The purpose of the gas lift in the kitchen is to open the upper tier of cabinets, which, according to their design features have top option discoveries. Modern furniture factories are increasingly equipping their products with gas lift structures. This mechanism has a number of advantages:

- Long service life;

- The open door is securely fixed in this position;

- The smooth opening stroke is self-adjustable;

- Absolute noiselessness of work;

- Production of fasteners for gas lift from the material of kitchen furniture;

- The facades of the furniture are devoid of numerous handles, which emphasizes the style of the interior.

Gas lift for kitchen set has simple mechanism ohm action:

- equipping the device with a classic gas spring, which has a smooth operation;

- when the cabinet door is opened at least 10º by spring force, it opens completely up to 90º;

- the opening process is controlled by a special hydraulic shock absorber, minimizing vibration and noise.

![]()

The design of any gas lift includes the following elements: a piston, a housing, a freely moving rod along the housing, a sleeve, sliding bearings, a valve, stuffing box packing, a piston seal and anther. Nitrogen is pumped into the body, which acts as a working medium. This filling takes place in industrial environment, which guarantees excellent tightness of the device. This fact can also be called a significant disadvantage - gas lifts are not suitable for repair.

Important: attempts to open the gas lift housing on your own can lead to the final failure of the equipment.

Choosing a kitchen gas lift

To choose a good and functional gas lift for kitchen furniture, you need to approach the process responsibly. The main characteristic of this device is the compression force, so it is important to know the weight of the door, which will put pressure on the lifting mechanism from above. There is a pattern: more massive furniture requires a gas lift with a high compression force of the spring mechanism.

The next criterion that affects the choice of equipment is the dimensions of the device, more specifically, its length. This setting depends on the size of the door being held. At the same time, it can be noted that as the length of the gas lift increases, there must be a mandatory thickening of its cylindrical body.

Gas lift for the kitchen can have 1 of 2 types of cabinet door opening:

- step by step;

- auto.

For structures with step by step algorithm openings include traditional options having a handle on the facade of the furniture. Automatically functioning doors have a slightly different opening mechanism - just one click on their surface is enough. This order of work has its advantages, especially for hostesses who are constantly in a hurry and running about their business.

Such doors are also convenient for those cooks who are short and simply do not reach the wall cabinets.

Wealth of choice

Almost all kitchen cabinets in last years equipped with gas lifts. The latest models of these devices have a more complex and high-tech lifting mechanism. The headset is mounted on the facades electric drive, facilitating the operation of furniture.

When purchasing a gas lift, you should pay special attention to 2 criteria:

- hanging cabinet size;

- device length.

To determine the compression force, it is necessary to carry out simple calculations: a load of 1 kg requires the application of a force of 10 Newtons. To determine the required compression force, you need to multiply the mass of the door (in kg) by 10.

If these calculations are difficult, you can use the online calculators that abound in many construction and furniture sites.

Manufacturers of gas lifts put mechanisms on the market that can withstand a standard load: from 60 to 140 Newtons. The buyer will be able to choose the best option for himself. All devices can have 1 of 2 mounting options:

- spring clip;

- plate fastening.

The first type is simpler, the mechanism is put on the mounting head in one motion. None special tools will not need.

The manufacturer guarantees the reliability of its devices for at least 5 years. Reliability of kitchen furniture - important parameter convenient operation of the kitchen.

Installation rules

Gas lifts provide kitchen furniture the quality that is so necessary for this room - the comfort of operation. The durability of the operation of the device directly depends on the literacy of the installation of the lifting mechanism.

The theoretical correlation between the compression force and the weight of the facade is rather conditional. If you follow these provisions, it turns out like this: a facade door weighing 10 kg must be freely lifted by a gas lift with a force of 100 Newtons. But in practice, such a large compression force will require the hostess to apply considerable effort to this lever.

Important: when purchasing furniture with custom finish facades (mirrors. Glass or plastic), the question of the possibility of equipping it with a gas lift should be asked to the manager of the outlet.

For work efficiency gas lift influences compliance with the filler dimensions. The slightest defect in this area will lead to incorrect operation of the lifting device. Incorrect work day by day is the reason for the rapid wear of components, the gas lift quickly fails and needs to be replaced. If the master does not have enough experience to comply with all the rules for installing the mechanism, you should contact the professionals. It will cost less than the cost of buying a new gas lift.

Facades are divided into overhead and inset according to the type of installation (for more details, see the article). This is important because it affects the use of certain hole patterns for gas lifts. For mounting additional mechanisms (repulsion system), separate filler holes are used.

The quality of the 4-hinged hinges also plays great importance. If you buy loops of dubious quality, this will affect the operation of the entire structure. Indeed, in the open state, a significant load falls on the locker door, which is partially distributed to the hinges.

Gas lift installation automatic type may suggest the presence additional function– tilt angle adjustment kitchen facade. When choosing lifting equipment for lockers, it is necessary to build on their quality (manufacturer's fame) and your financial capabilities.