A profile for a stretch ceiling is the main element of high-quality do-it-yourself installation. Stretch ceiling profiles

The quality of installation of a stretch ceiling largely depends on the profile on which the stretch fabric is attached.

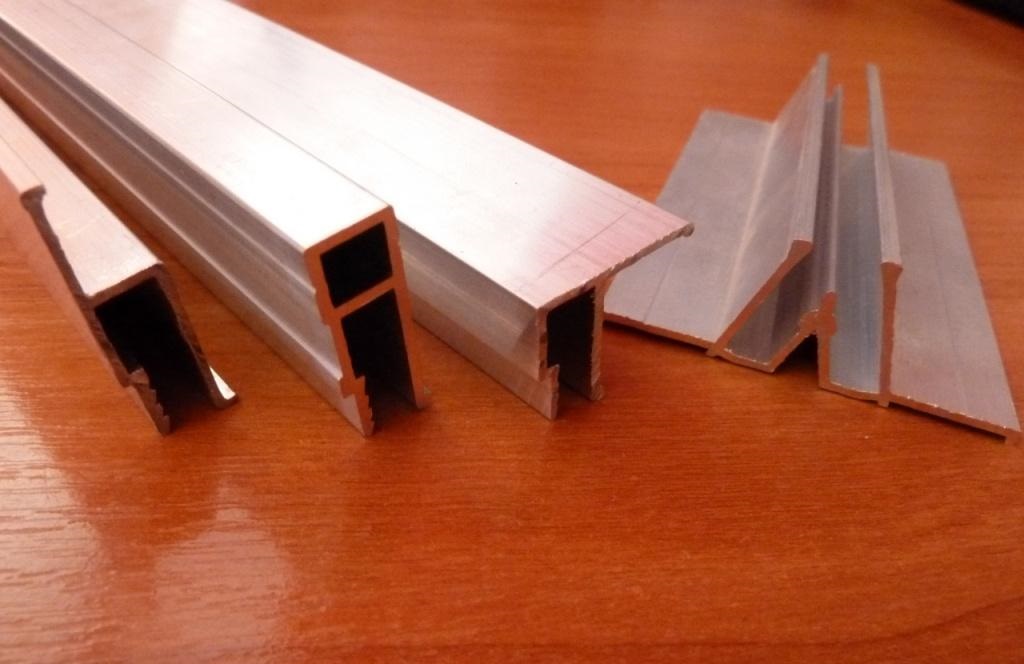

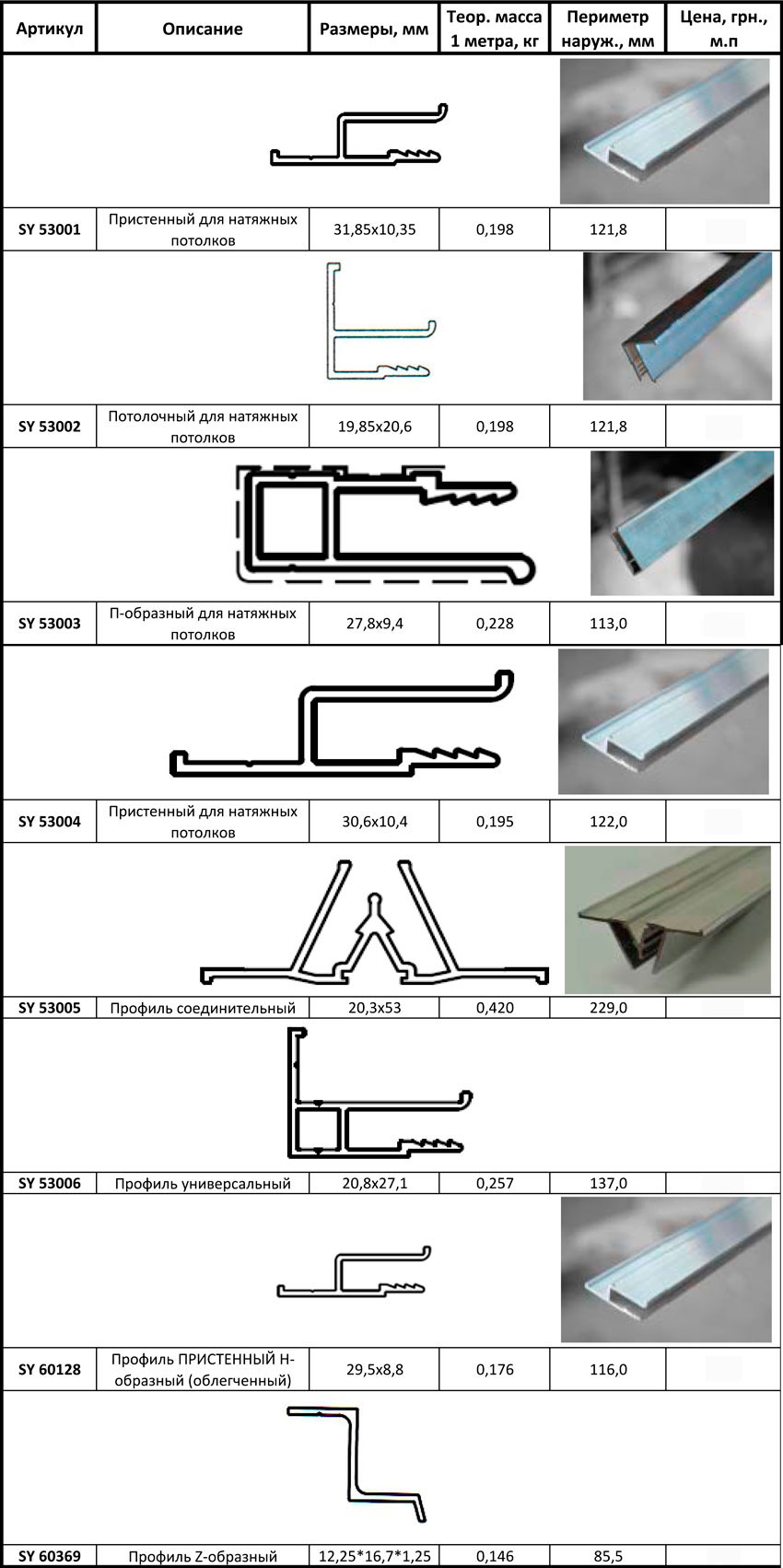

Our company sells from stock and manufactures to order the most progressive finishing material- aluminum profile (baguette) for stretch ceiling of 3 types: wall, ceiling, universal. Their difference lies in the types of fastening during installation:

wall mounted to walls and other vertical planes of the room;

ceiling - to the ceiling and others horizontal surfaces;

universal can be mounted on both vertical and horizontal planes and is used, as a rule, in complex ceiling structures, when it is necessary to wrap the ceiling around niches and stationary furniture.

You can also purchase an aluminum glazing bead from us, used for fixing stretch fabric and a divider designed to connect 2 tension sheets in case you need to bypass columns or in case of installation of ceilings on an area of more than 50 m².

The aluminum baguette is made of high quality aluminum alloy, thanks to which it does not break, does not bend, does not corrode, spots do not form on the tension web. Throughout the entire operational period, it provides reliable fastening of the ceiling.

Advantages of aluminum profiles for fixing the stretch web:

does light construction but durable;

increases the life of the entire ceiling system;

does not create an unnecessary load on the walls;

promotes easy and quick installation ceiling;

makes it possible to implement any exclusive design solution stretch ceiling.

The company "Intormetall" guarantees the quality of stretch ceiling profiles, because. cooperates with the best domestic manufacturers of aluminum profiles.

Aluminum profiles for stretch ceilings manufactured according to GOST 8617-81.

Stretch ceilings are modern, original and practical solution in interior decoration. When creating them, installers use fabrics of various styles, colors and textures, as well as baguettes to fix them on the surface. Baguettes are one of the main components of the entire structure of the stretch ceiling. They are made of PVC and aluminum, and each material has its own application features and advantages.

Advantages of aluminum profiles for stretch ceilings

It is believed that aluminum profiles are more reliable and durable when creating stretch ceilings. They are used when using harpoon technology PVC mounting films. The main advantages of profiles for aluminum stretch ceilings are:

quick assembly and dismantling PVC sheets;

durability and reliability of fastening;

high strength, allowing to withstand the force of tension;

excellent angle retention when notching;

elimination of uneven walls and ceilings due to the rigidity of the baguette itself.

Varieties of aluminum profiles

Aluminum profiles for stretch ceilings are made:

Ceiling. Allow to carry out fastening of a stretch ceiling to horizontal surfaces. In this case, the height loss is up to 2 cm. Slots and fasteners are closed with masking tape after the installation of the panel.

Wall. Baguettes of this type are designed for attaching stretch ceilings to vertical surfaces. They are installed in increments of 15 to 20 cm, while the height loss is up to 3.5 cm. All resulting gaps are sealed with masking tape.

Universal. They have excellent rigidity and allow you to attach canvases to walls and ceilings in increments of 50 cm. The loss of ceiling height when using such a baguette is up to 3 cm. All gaps are carefully masked with a special tape.

Another type of aluminum profile can be called a separator, which is used to connect two sheets, if necessary, bypass columns or to overlap large areas ceiling surface. When using an aluminum separator, the ceiling height loss is up to 2 cm.

Harpoon technology for fastening stretch ceilings

When using aluminum baguettes, only harpoon fastening technology is used to install stretch fabrics. It is considered one of the highest quality, reliable and durable. Installers make edging from strong metal around the entire perimeter of the film, and then fix it in the profile. A big advantage of this technology is also significant savings on the material for the stretch ceiling.

The PVC film, when heated, is stretched first diagonally, and then along the perimeter. When cooled, it forms a smooth and perfect flat surface. This technology does not require additional installation skirting boards, since the entire stretch ceiling system is already hidden.

You can profitably purchase aluminum profiles for stretch ceilings of any size and variety at Intormetall. Contact.

Stretch ceilings - one of the most popular ways to finish the ceiling. Rich choice ceiling covering provides an opportunity to choose film or fabric ceiling for every taste.

However, a stretch ceiling is not only a canvas, but also a frame on which it is stretched. For the installation of a stretch ceiling, in addition to the canvas itself, special components are required. Their choice depends on the method of installing the canvas, the complexity of the bends of the ceiling, the need to connect several canvases, etc. The main fasteners are profiles, also called. The profile for stretch ceilings is made special, and there are different kinds profile.

Types of profiles for stretch ceilings

According to the material from which the profile is made, there are metal and plastic profile.

- Aluminum profile for stretch ceilings is made of aluminum alloy. It is strong, well withstands the weight of large canvases.

- The plastic profile is made of rigid PVC. It is light in weight, bends well, is easy to install and, most importantly, it is mounted closer to the ceiling, due to which much less room height is lost.

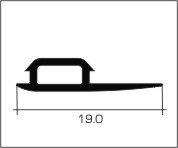

Photo 1 - Plastic ceiling profile

Photo 2 - Aluminum wall profile

According to the type of mounting surface, ceiling, wall and universal profiles can be distinguished.

- Ceiling the profile is used for fastening the stretch ceiling fabric to the ceiling and any horizontal surfaces.

- wall the profile is used to fasten the stretch ceiling to the walls and any vertical surfaces.

- Universal the profile is mounted on any horizontal and vertical surfaces for attaching the stretch ceiling fabric. It is especially convenient to use it in unusual places: complex structures, niches, when leading the ceiling around stationary furniture, etc.

Photo 3 - Universal profile, mounted on any surface

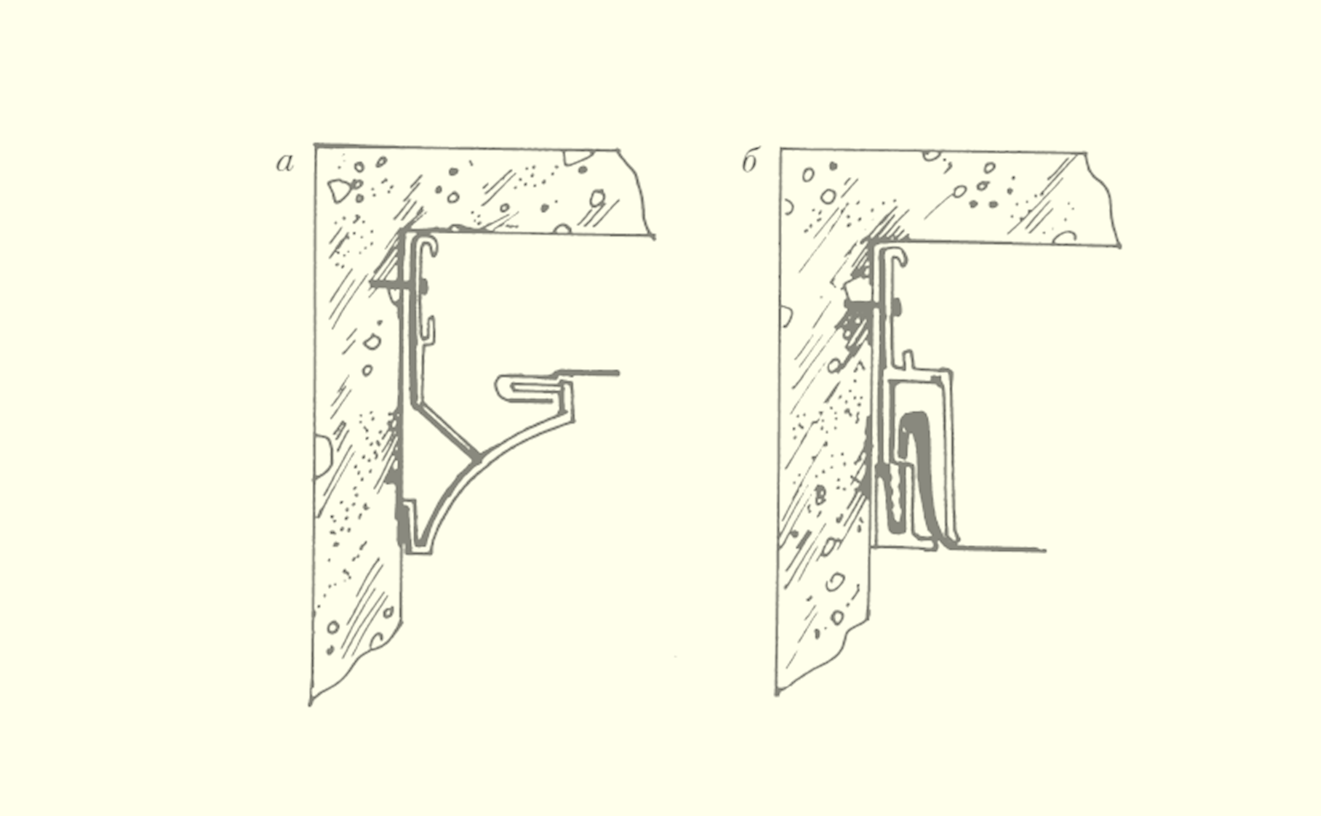

Depending on the visibility of the profile, after the installation of the stretch ceiling, a visible and invisible profile is distinguished.

- Visible the profile is noticeable after installation - its lower part acts as a decorative frame.

Photo 4 - Visible profile for mounting a stretch ceiling

- Invisible the profile after installation of the ceiling is hidden under the PVC film.

Photo 5 - Invisible profile for mounting a stretch ceiling

There are special types of profiles designed for specific connections depending on the system, installation location and design complexity.

- Dividing profile can be different design. It is used when joining two different canvases, bypassing columns, covering large areas. The joint can simply be a smooth transition from one canvas to another or have an insert between them.

Photo 6 - Separating profile for joining two stretch ceiling sheets

- Double or separating inclined profile allows you to fix two blades at once. Used to create complex highlights ceiling structures, for example, using a translucent canvas. This creates the effect of a starry sky.

Photo 7 - Double profile for parallel tension of two canvases

- Angular the profile consists of two parts connected during installation. It is used for corner joining of canvases, bypassing building elements and creating various multi-level ceiling structures. For the same purpose, a special structural profile is used.

There are corner and structural profiles with evenly spaced notches for easy bending. They are used to install curved ceilings and complex curved multi-level ceiling structures.

Photo 8 - Corner and structural profile

- Plastic baguette "clothespin" for seamless ceilings used for the installation of fabric stretch ceilings.

Photo 9 - Baguette for a seamless fabric ceiling

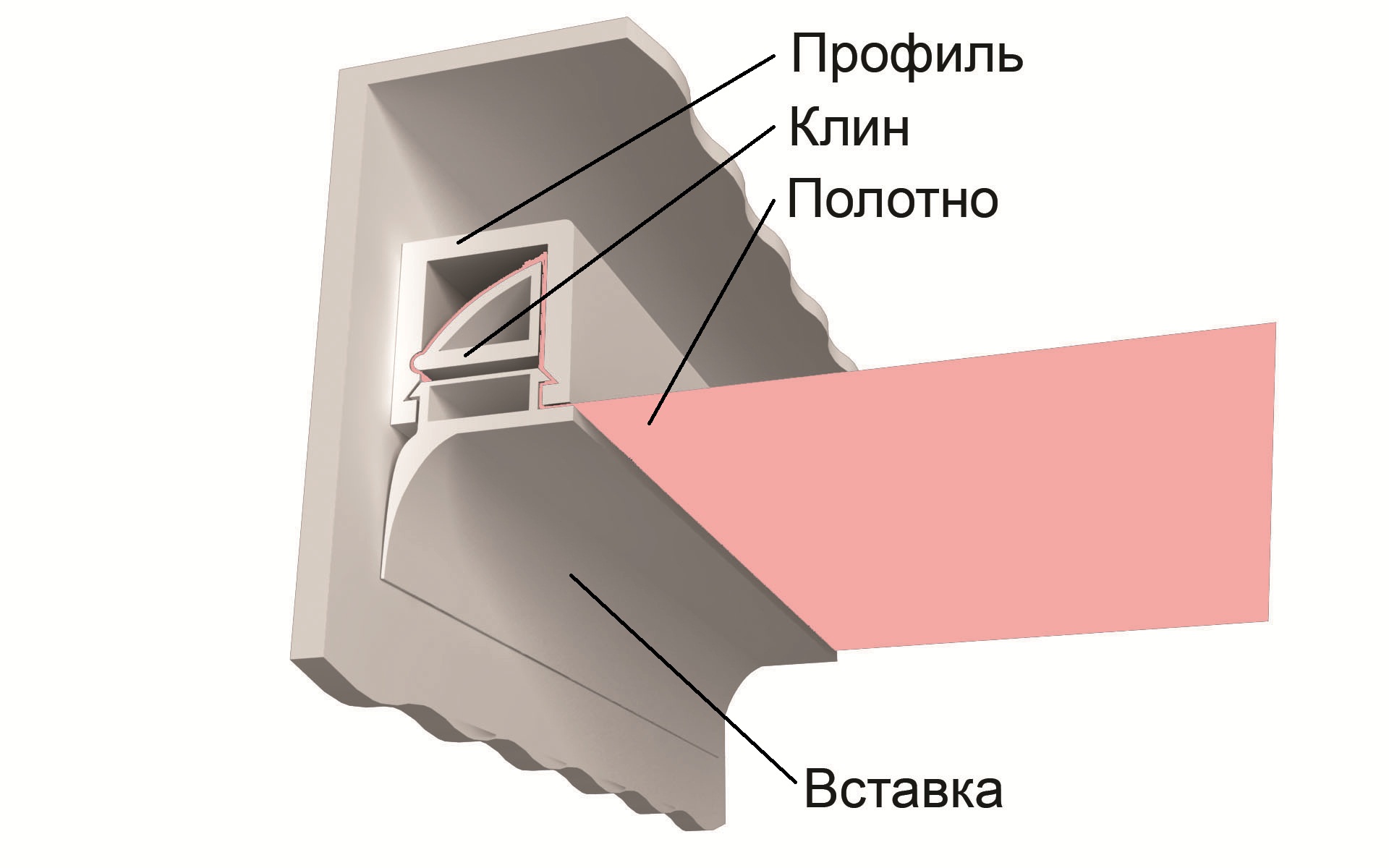

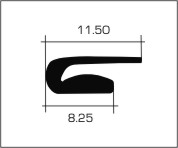

- bead the profile is used with a glazing bead system for installing a stretch ceiling. The canvas is stretched, laid inside the profile and a glazing bead or wedge is inserted into the profile over the film.

Profile for stretch ceilings, price

You can buy a profile for stretch ceilings, the price of which differs depending on its type, in one of the online stores. The descriptions of each product indicate the material, weight, minimum distance to the ceiling during installation, installation system, etc. Approximate prices for different profiles for stretch ceilings when buying in bulk:

- aluminum bead profile (2 m) - about 30 rubles.

- PVC profile "clothespin" wall (2.5 m) - about 40 rubles.

- dividing aluminum profile - harpoon system (2.5 m) - about 80 rubles.

Accordingly, retail prices will be an order of magnitude higher, and large wholesale prices will be even lower.

Previously, stretch ceilings were used exclusively in cases where it was necessary to hide visible and fairly strong defects in the ceiling surface. But today tension structures are not just functional, they are also very beautiful and are important element decoration of many interiors.

In addition to the canvas itself, in the design of such a ceiling there is a profile, also called a baguette. The profile is fixed on the walls at a certain height or on a concrete or wooden floor, and the canvas is stretched. It, in turn, is fixed in the profile clamps and stretched to a perfectly flat surface.

A good baguette should be reliable, durable, easy to install and when stretching the ceiling. In addition, he must firmly clamp the canvas and prevent it from tearing or releasing in the future. It is difficult to choose a profile that would meet all these requirements without a minimum of knowledge.

Profile views

A baguette for a stretch ceiling is a long profile of a complex section, obtained by pulling a heated and plastic material through a hole of the appropriate shape on special equipment. This process is called extrusion.

Conventionally, the profile is divided into two parts - a lock, which serves to fix and tension the ceiling sheet (made of polyvinyl chloride or polyester fabric) and a plane for fasteners. The task performed by the last part is clear from the name - holes are drilled in this plane when installing baguettes, after which fasteners (for example, screws with dowels) are inserted and the profile is fixed under ceiling.

According to the surface of the fixing, it is divided into the following types.

- Wall - baguette is attached to the wall under the main ceiling or on any other vertical surface.

- Ceiling - the lock and the plane for fastening are designed in such a way that the profile must be installed on a concrete or wooden ceiling or any other horizontal surface.

- Versatile - suitable for both wall and ceiling mounting.

Important! A universal baguette is often used for stretch ceilings in rooms with complex geometry. For example, if there are niches in the room or there is furniture that occupies the entire space from the floor to the ceiling, and it is not possible to stretch the canvas over it.

In addition, there are special types of baguettes.

Important! A split profile is used not only for rooms with a large area, but also in cases where it is necessary to install two or more canvases different colors and forms. This allows you to diversify the ceiling decoration in the room and realize unusual design ideas.

Also distinguish visible and invisible stretch ceiling profiles Everything is simple here - the first can be seen even with a stretched canvas, while the second is completely hidden behind it. It should be understood that the visibility of a baguette does not mean that your guests will be forced to contemplate structural elements stretch ceiling - the profile is closed without problems with a special decorative overlay. And some of the visible profiles are already equipped with an attractive underside.

Types of profiles: a - visible, b - hidden

Baguettes for stretch ceiling - materials

Today, such profiles are made either from aluminum or from rigid polyvinyl chloride (PVC). Both materials have their own characteristics, advantages and disadvantages. Let's consider them in a little more detail.

Aluminum baguettes appeared first, therefore they were used much more often before - even after the appearance plastic analogues- out of habit. Such profiles have considerable strength and reliability, and most in the best way suitable for fixing large massive panels. Accordingly, there are no complaints about the durability of aluminum baguettes.

The disadvantage of such a profile for stretch ceilings is the continuation of its advantages. With respect to steel, aluminum is, of course, a light, soft and pliable metal, but compared to polyvinyl chloride, it has excessive rigidity and mass. Therefore, it is very difficult to create multi-level and bent structures with it. In addition, holes for fasteners in an aluminum baguette must be drilled in advance, “on the ground”. And, obviously, metal profiles are more expensive.

plastic baguettes appeared later than aluminum ones, but over time they overcame the mistrust of specialists and got their share in this area. Such profiles are distinguished by ease, low price are easier to deal with. Polyvinyl chloride baguettes bend well, therefore, with their help, unique and unusual stretch ceilings of complex shapes are created. But for too large and, accordingly, heavy panels, they are not suitable - under heavy load, the plastic profile can bend or even burst (the latter indicates a low quality product and a violation of manufacturing technology).

Types of clamps

The fabric of the stretch ceiling is attached to the baguettes with clamps. These clamps come in three types, differing in design, reliability, complexity of installation and cost.

bead clamp. Profile for fastening of this type is made with a lock certain form and attached glazing beads - aluminum slats of triangular section, where one of the sides is rounded. With this method of fastening, the length and width of the canvas must be greater than the corresponding indicators of the room.

The canvas is driven into a baguette, and then a glazing bead is inserted into the lock, which presses it against the profile and fixes the material. The installation of the lining completes the process, which presses everything from below. In addition, she serves decorative element stretch ceiling.

The main advantages of such a clamp are low cost and ease of use. In addition, it is relatively easy to dismantle the glazing bead to gain access to the ceiling. But during the installation process, the canvas is deformed, so it is too often to dismantle and reverse mounting Not recommended. Also, this method of fastening is not the best suited for a heavy canvas - it can pop out from under the glazing bead at a certain moment.

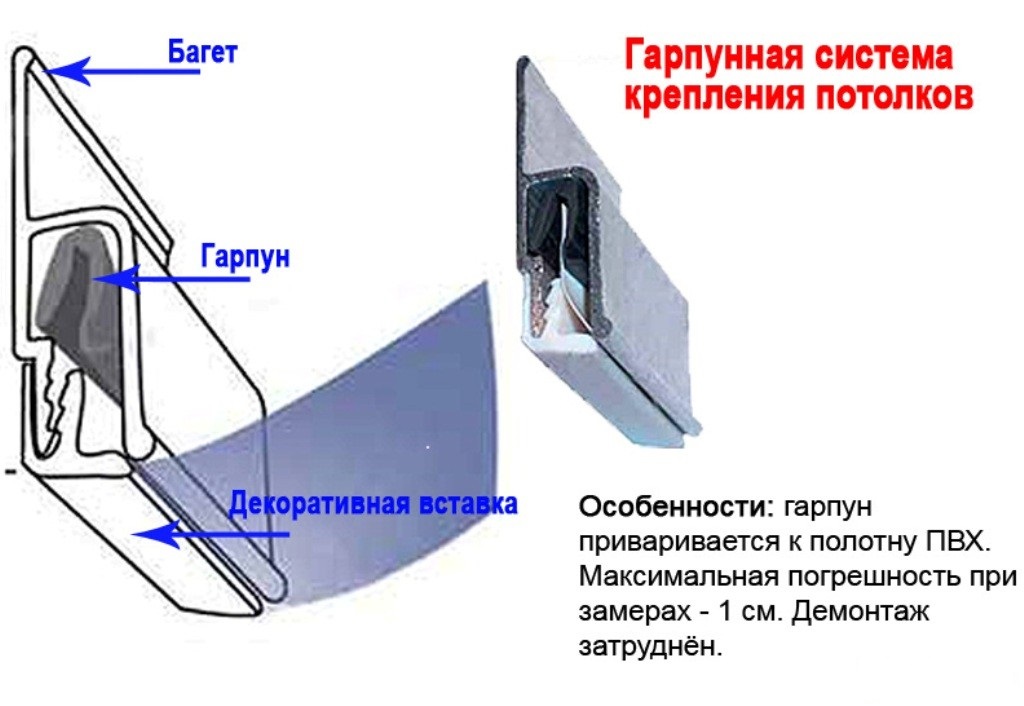

The next type of clamp, which has become widespread - harpoon. With this method of fastening, an edging is attached around the perimeter of the canvas in the form of hooks of complex section, which are called harpoons. During installation, the film is heated and fixed in a baguette with the help of harpoons, first in the corners, then along the rest of the perimeter. The hook, entering the profile, is compressed, but then, unclenching, it catches on the protrusion in the section of the baguette.

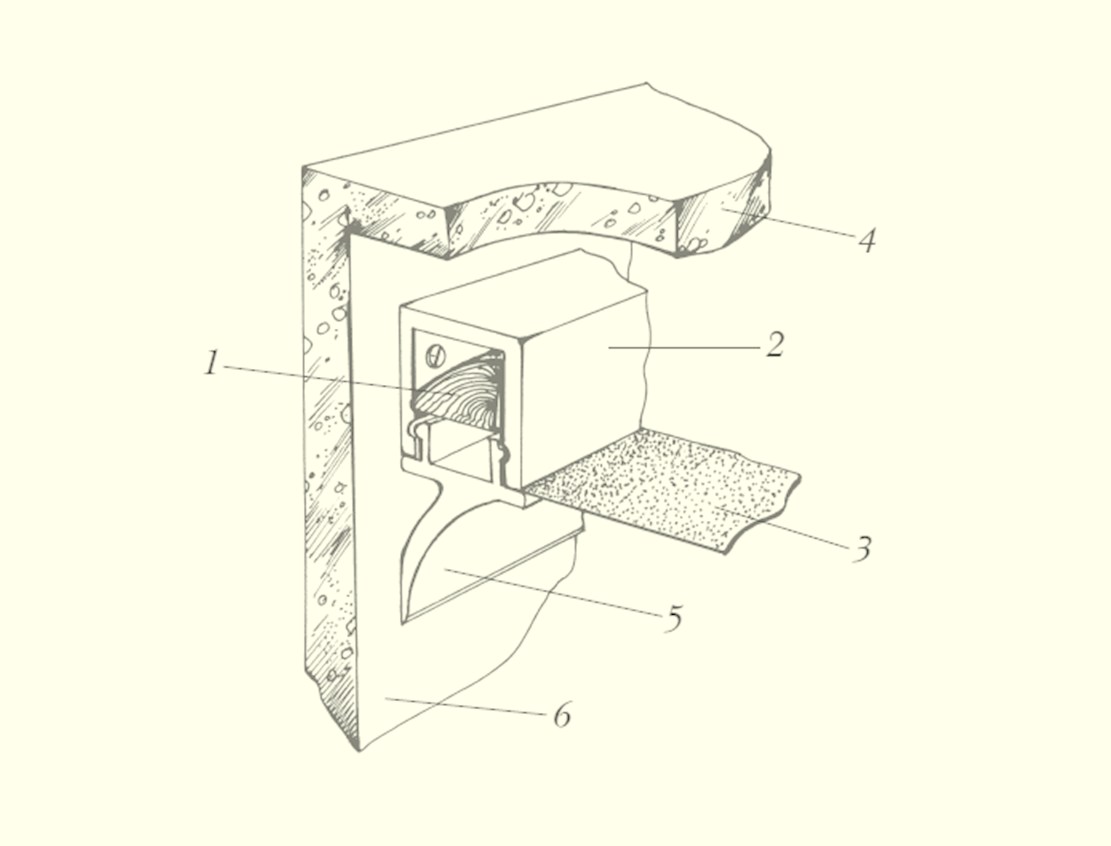

Harpoon method of fastening a stretch ceiling: 1 - harpoon; 2 - baguette; 3 - canvas; 4 - main ceiling; 5 - decorative overlay; 6 - wall

Fixation in this way is very reliable, which allows the use of a harpoon clamp for a large and, accordingly, heavier canvas. But the price of such a profile is significantly higher than that in which the fixing occurs with the help of glazing beads.

Important! The hooks themselves are attached to the PVC film at the stage of fabrication on special equipment. In this case, the dimensions of the room must be carefully maintained, which somewhat increases the time for making the film.

Another principle of fastening - clip-on. It is used somewhat less frequently, and mostly for fabric ceilings (such as CLIPSO). This type of baguette has a clamp of two planes, between which the canvas is inserted during installation. The result is a fastening of medium reliability.

Calculation and preparation

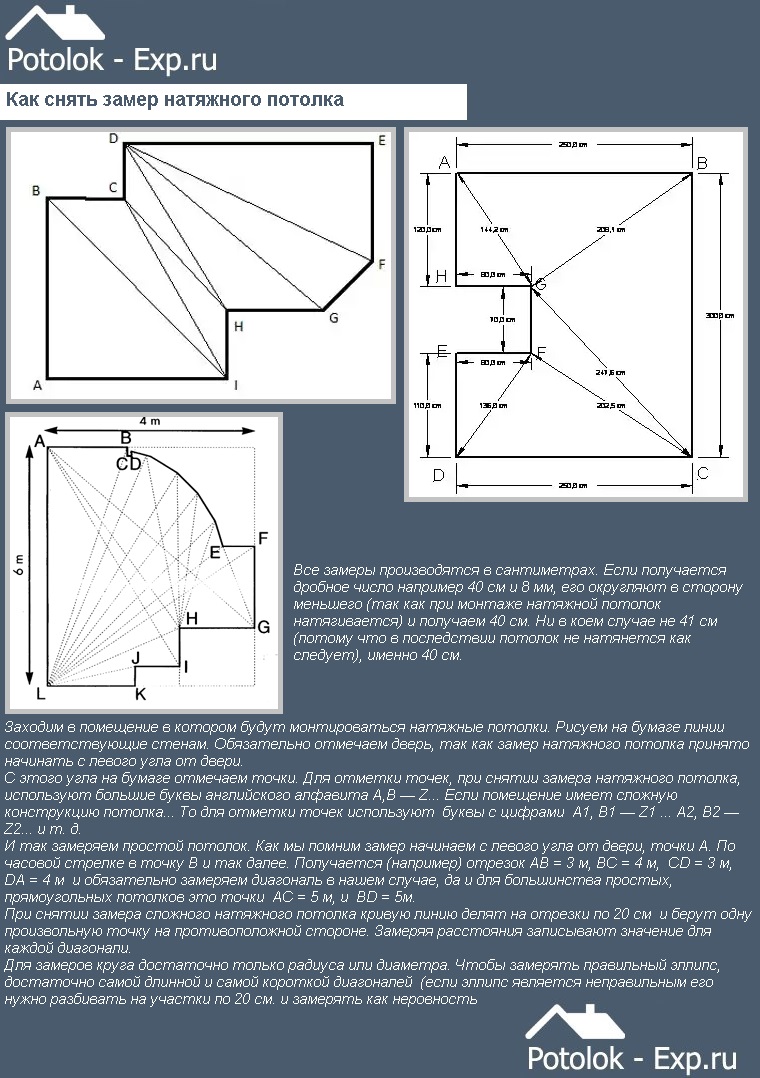

The first stage of any repair and finishing works- calculation and planning. Before you start fastening the baguettes, you need to measure all the walls of the room along the length.

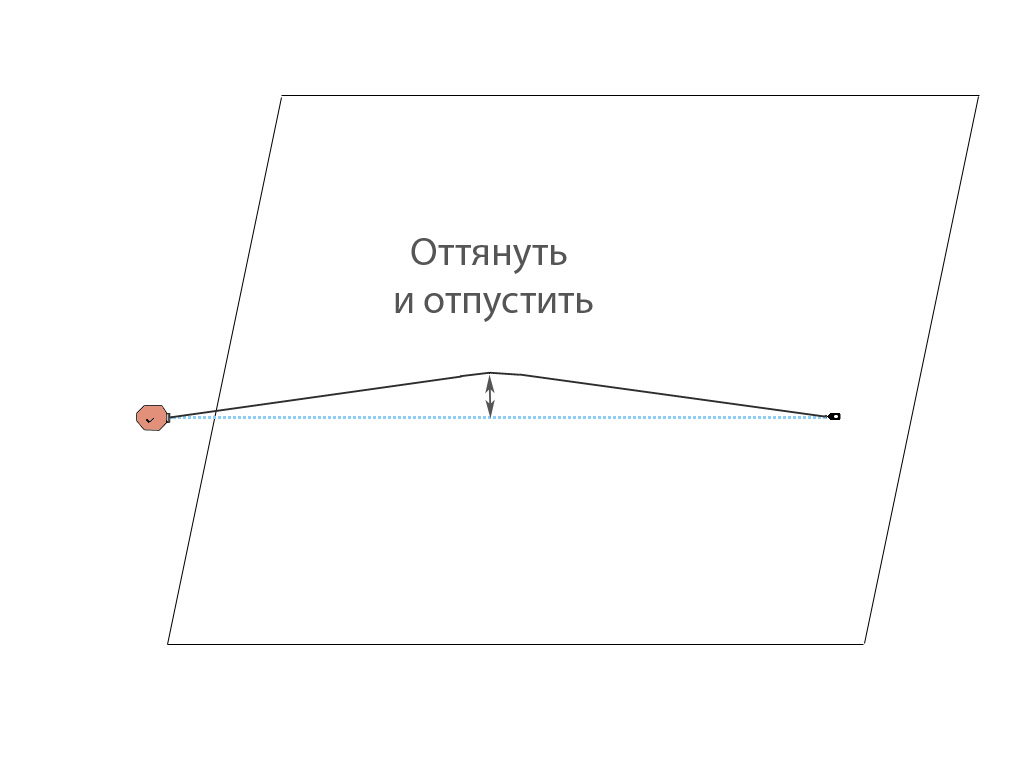

In addition, it is necessary to measure the length of the diagonals - the rooms during construction are not ideal and this must be taken into account. For premises complex shape or with curved sections, this process becomes more complicated.

After completing the measurements, it is necessary to determine how many materials will be needed. List example the right materials and tools are shown in the table below.

Table. Tools and materials necessary for the installation of baguettes.

| Name of material or tool | What is used for | Quantity |

|---|---|---|

| For fixing stretch ceiling film | On average, one profile per 2.5 meters of the perimeter of the room |

| For fixing the baguette to the ceiling or wall | Fastening pitch - from 120 mm to 200 mm, that is, from 12 to 20 screws per baguette |

| To close the bottom of the baguette or directly to decorate the stretch ceiling | On average, one plinth per 1-2.5 meters of the perimeter of the room |

| For comfortable work under the ceiling | 1 PC. |

| To create holes for fasteners in a ceiling or wall | 1 PC. |

| For fastening baguettes with screws to a wall or ceiling | 1 PC. |

| For measurements | 1 PC. |

| For cutting off the excess part of the baguettes and trimming before installation in the corners of the room | 1-2 pcs. |

| For measurements | 1-2 pcs. |

| To control the position of the baguette and to mark the ceiling | 1 PC. |

| Choose the length depending on the perimeter of the room |

|

| For marking the location of baguettes | 1-3 pcs. |

Important! To work with an aluminum profile, you will need a drill and an appropriate set of drills for making holes for fasteners immediately before installation. The fact is that drilling, leaning a baguette against the ceiling, is extremely inconvenient.

It is worth saying that profiles and fasteners should be purchased with a margin of 10-25% - some of them may be defective, break during operation or get lost.

As for the preparation for installation, it is the same as for other work related to finishing the ceiling: concrete or wooden floor completely cleaned of the remnants of the previous finish, dust and dirt. Wallpaper, plaster and old paint remove with a spatula, well-holding paint - with solvents, water-based or whitewash - with soapy water. After that, it is necessary to repair all cracks in the ceiling with putty.

Stretch ceiling installation

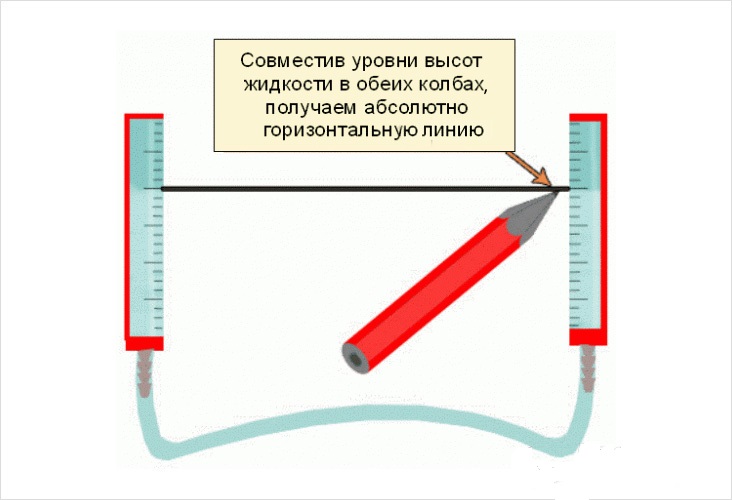

First you need to mark out where the baguettes will be located. Marking is carried out using either a laser level or a hydraulic level. Consider phased work with both the instrument.

Marking the location of the profile using a laser level is as follows.

Photo - laser level

Step 1. The height is measured from floor to ceiling in all corners of the room. From the place where the result is the smallest, the markup will begin.

Step 2 The laser level is installed in a place where you can see how you can large quantity corners in the room. If there is a hard-to-reach niche, then the marking should be repeated, but rearranging the tool so that this place is accessible to the laser beam.

Step 3 The laser level makes strictly horizontal marks in each corner of the room. They are transferred directly to the wall with a marker or pencil.

Step 4 If possible, it is necessary to immediately adjust the height of the marks so that in the lowest corner of the room there is 3-5 cm between the mark and the ceiling.

Step 5 With the help of a laser level and a paint thread for beating between the corners, a horizontal line is drawn according to which the baguettes will be installed.

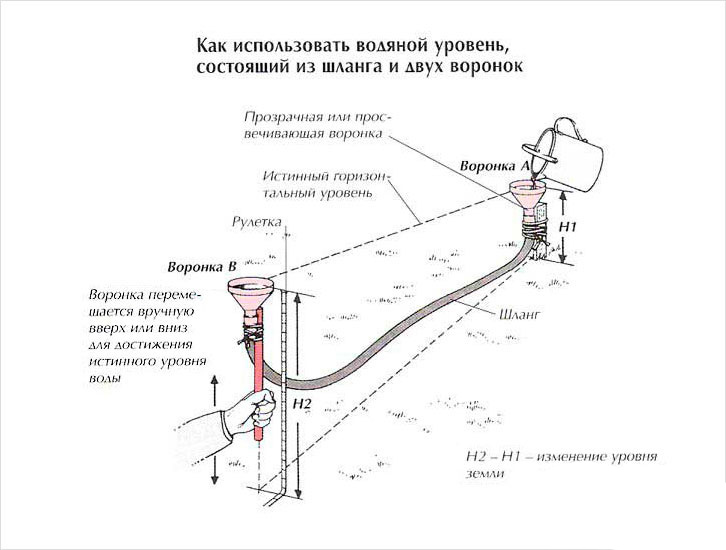

Marking places for a profile using a hydraulic level occurs in a similar way, but adjusted for the specifics of the tool.

Step 1. The height is measured in the corners and the corner with the smallest result is found.

Step 2 The level is filled with water. In this case, the liquid should not be cold or hot, the temperature should correspond to the air temperature in the room. In addition, make sure that there are no kinks in the hose and bubbles in it and flasks.

Step 3 Two people stand with level flasks under the ceiling, you should start from the lowest angle.

Step 4 From the ceiling in this place, 3-5 cm or more is measured, if necessary, a level flask is applied to the mark.

Using a water level to mark the ceiling

Step 5 The second person in the other corner must place the second flask against the wall so that the marks match. As soon as this happens, and the water stops oscillating, a mark is placed in the new corner.

Step 6 The previous step is repeated for each next corner.

Step 7 A paint thread is pulled between the corners and a horizontal line is beaten off along which the baguette will be installed.

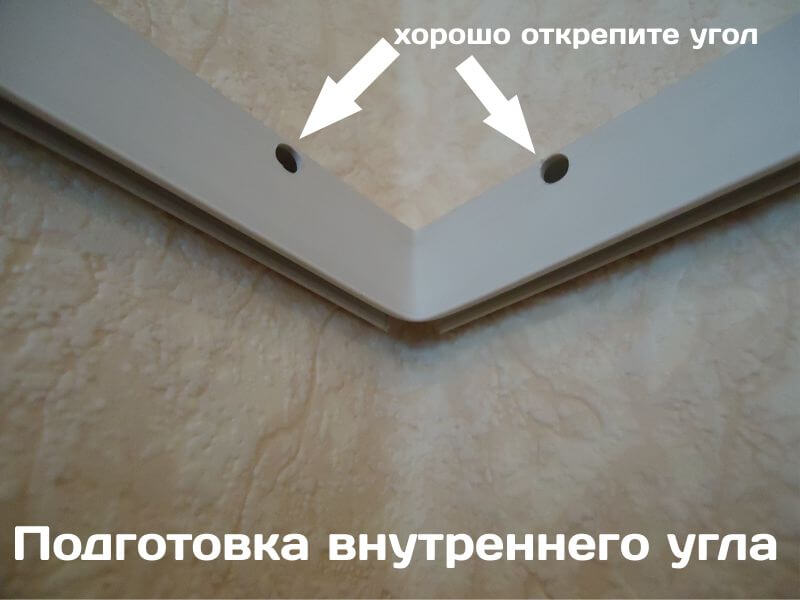

Now you need to prepare baguettes for installation in the corners of the room. It is often suggested that they be connected in the same way as ceiling plinth– join two elements whose edges are cut at 45°. But for a baguette, this method can hardly be called optimal - in the corners the profile experiences heavy loads, and deformation of the elements can occur at the junction. Because the work becomes more complicated, baguettes need to be filed on the back side and bend the front. The illustrations below show how this is done correctly.

Further steps for installing a profile for stretch ceilings are as follows.

Important! It is advisable to glue the joints between the baguettes with construction tape.

As in any other repair business, it is very important to carefully follow the technology and plan everything well when installing stretch ceiling profiles. Then you will get a result that will last a very long time.

Video - Installation of a stretch ceiling profile

| Profile view | Name | Price for 1 r.m. with VAT from 2.5 m. |

|---|---|---|

| Lightweight wall baguette L=2.5m | 28 R | |

|

Baguette ceiling (lightweight) L=2.5m | 31 R |

|

Divider for stretch ceilings L=2.5m | 66 R |

| Bead profile, unlightened L=2.0m | 31 R | |

|

Fender L=2.5 m | 33 R |

|

Insert - TL white for wall baguette (150m) | 8 R |

|

Sealing corner | 11 R |

|

Insert KL for glazing bead system | 8.5 R |

|

Harpoon - L black for wall baguette (275m) | 7 R |

High-quality aluminum profiles - a guarantee of the durability of the stretch ceiling

Stretch ceiling is beautiful, durable and reliable. But it will be so only when the aluminum profile for stretch ceilings is correctly selected. The subtleties that need to be paid attention to in this case are the subject of our article.

What profiles for stretch ceilings are

Depending on how the profile is attached to the plane, profiles are usually divided into the following categories:

- Ceiling.

- Wall.

- Universal.

In addition, baguettes (as professionals call profiles) may differ in how the tension fabric is fixed in them. Most often there are profiles for stretch ceilings with embedded glazing beads or under a harpoon.

The first option is used when fabric or seamless stretch fabrics are mounted. And if it is planned to manufacture a membrane ceiling, then the second option is used. For the manufacture of such ceilings in Moscow, PVC film from polyvinyl chloride is used.

More about profiles for harpoon-type stretch ceilings (for harpoon)

The name of this profile comes from a mortgage profile - a harpoon - a method used to fasten a film in a baguette. The profile itself consists of the following parts:

- part for fastening;

- groove for fixing the comb harpoon.

Along the edges PVC films, which is better to buy in bulk, a flexible profile called a harpoon is welded. It is tucked into the fixing groove of the baguette, which has a wedge-shaped shape. This is done with a spatula. There it is fixed with a comb.

Thanks to the specially made hardening of the aluminum baguette from the manufacturer, it is able to withstand a significant load for a long time. A stretched film is a serious test. However, some profile manufacturers give a 50-year warranty on baguette performance if purchased from them.

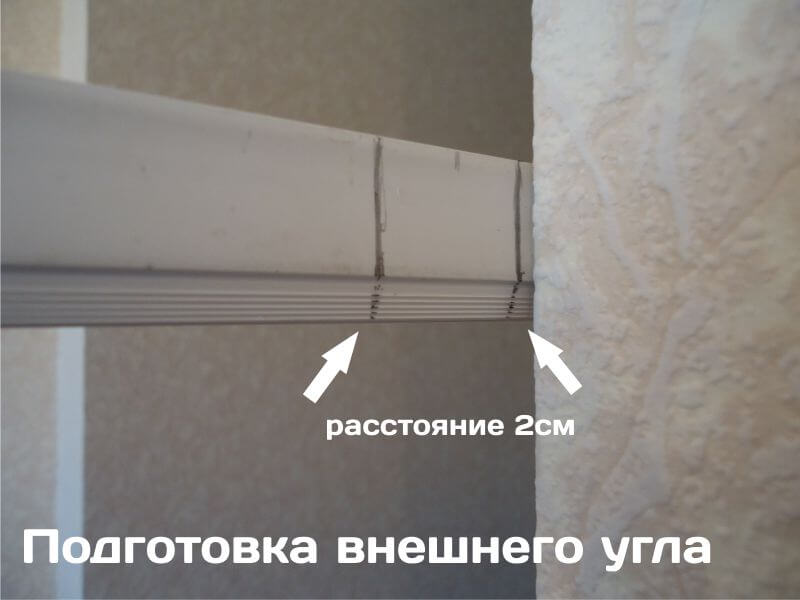

The harpoon baguette belongs to the category of invisible, due to the fact that it is possible to mount it on the ceiling. For this purpose, a mounting shelf is used, which is located at an angle of 90 about relative to the wedge groove. For reliable fixation, the fastening spacing should be no more than 20 cm.

Briefly about wall and universal aluminum profiles

At wall profile, the price of which is quite affordable, there is a straight shelf designed to attach it to the walls. For its peculiar appearance, many call it an h-profile. The rules for fastening this type of baguettes are the same as for harpoon ones.

Universal baguette, as its name implies, can be mounted both on the wall and on the ceiling. It is used in cases where stationary furniture or niches wrap around the ceiling, respectively, and its cost is somewhat higher.

Stretch ceilings are widely used in design modern apartments, private houses and cottages. Installation of a stretch fabric is made on a plastic or aluminum profile for stretch ceilings. How to choose a profile for a stretch fabric and install it on the ceiling is described in detail on this page.

Depending on the method of fastening to the plane, the profiles, or as professionals call them "baguettes", are divided into the following categories:

- Ceiling

- Wall mounted

- Universal

Baguettes also differ in the way the stretch fabric is fixed. Usually you can find a harpoon-type baguette and a baguette with a fixing glazing bead. The first option is used for fastening stretch membrane ceilings made of PVC PVC film. The second option is used to install fabric or seamless stretch fabrics.

A profile for a PVC film ceiling is called a harpoon profile. This is due to the way the film is fixed in the baguette groove. The harpoon-type profile includes the following elements made in a monolith by cold stamping:

- Mounting profile

- Locking wedge groove

Decorative pvc skirting board, which closes the gap between the stretch fabric, can be purchased separately from the manufacturer of the stretch ceiling. A flexible profile - a harpoon - is welded to the edge of the PVC film. It is tightly driven with a spatula into the wedge fixing groove of the baguette, where the harpoon engages with the comb.

Special hardening of the aluminum profile allows it to withstand heavy loads stretched film over a large period of time. Some manufacturers of aluminum baguettes claim that the service life of their products is 30-50 years.

The harpoon profile can be mounted on the ceiling - this is the so-called invisible baguette. It has a mounting shelf located at an angle of 90 degrees to the wedge groove. This shelf is mounted with self-tapping screws and dowels to the existing concrete floor.

It's important to know! To securely fix the aluminum profile for stretch ceilings, it must be fixed with self-tapping screws and dowels in increments of 15-20 cm.

At the joints of two baguettes, the fastening step is reduced to 2 cm. It is impossible to join the profile in the corners. In order to fix the baguette in the corner, it is cut with a segment at an angle of 45 degrees and bent at a right angle.

The wall profile has a straight shelf for fastening with self-tapping screws to the walls. For the type of cross section, it is often called an h-profile. The rules for mounting a baguette on the walls and how to fix the profile to the ceiling are completely identical.

It's important to know! After the trimming of the aluminum profile has been completed, its edges must be processed sandpaper to remove burrs.

Universal aluminum profile for stretch ceiling is designed for mounting on vertical and horizontal planes. It is recommended to use it when bending around the ceiling of stationary furniture or niches. As a rule, such a baguette is used for complex ceiling structures.

A profile can be executed in a visible version when, after installing it decorative shelf forms a border around the perimeter of the stretch fabric. You can also find an invisible option. After its installation, the stretch fabric completely hides the baguette, and the gap between the wall and the canvas is closed with a decorative PVC cap.

If the area of \u200b\u200bthe room is large, then two sheets of PVC film have to be joined, because its width is limited. In this case, a separating aluminum profile is used.

It has two shelves for attaching to existing ceiling and two adjacent locking harpoon grooves. The joint between the grooves can take place for a decorative insert or join the canvases tightly to each other. The main advantage of the aluminum profiles of the harpoon system is that they allow you to dismantle PVC ceiling and install it again.

Important to remember! Before fixing the profile to the ceiling, the floor surface under the baguette must be aligned in one horizontal plane along the perimeter of the room.

Tension web profile with glazing bead

A harpoonless method is used to fasten a tension fabric web. In this case, aluminum baguettes are used with a special rail (glazing bead), which is inserted into the baguette groove and fixes the ceiling sheet.

As well as harpoon profiles, they are produced for mounting on walls, ceilings or in a universal design. Baguettes are also provided for joining canvases, but this is for a very large rooms, since the width of fabric seamless ceilings is 5.1 m, which is enough for almost any room in an apartment or private house.