Wire stripping machine. How to strip insulation from wires of various types. Which tool to choose

In electrical activities, accuracy and accuracy in the processing of materials are especially important. The quality of the current-carrying element is determined by the reliability of the connections and the absence of defects on the line. As practice shows, a considerable part of the malfunctions in the operation of network communications of this type arise precisely because of errors in installation. The key to quality work is the use of the right tools. For example, in the question of how to strip a wire, you should not resort to improvised means that are not intended for such operations. Cleanly and evenly, without damaging the working elements, special tools will allow you to remove the insulation.

stripping

The traditional device for such tasks is a special kind of pliers with precision holes with different diameters. Also, the tool provides corrugated sponges and straight blades. You can say this universal tool for stripping wires, as it also allows you to grab and cut cables of different gauges. If functionality is not important, but high speed and ease of use, then you should turn to the family of wire cutters and pliers. Just a few manipulations are required to adjust the device to the size of a particular wire, after which it is just as easy to remove the insulation.

It has already been noted that improvised tools should not be used in such work. First of all, this rule applies to ordinary knives, but this does not mean that, in principle, this category of household utensils cannot be used in electrical work. For example, there is a cable cutter for wires, the characteristics of which are just focused on removing outer coatings. The tool is characterized by a sickle-shaped blade, as well as the use of high-strength tool steels in the base.

Features and benefits of stippers

Separate attention deserves the category of stippers, which are designed for spot removal of insulating layers from cables. different type. The design of the device is represented by two handles and jaws that form wells of various sizes. In the process of work, the master places the wire in one of the free openings, clamps the jaws and pulls the cable away from the capture point. sharp blades introduced into insulating coating, cutting it off from the main body and leaving the metal core bare. In order to increase the functionality of the stripper for stripping wires, it can be equipped with holes not only in the working area of the main jaws, but also on the handles. From an operational point of view, the use of stippers is justified for two reasons. Firstly, a high quality cut of the insulation is ensured without harming the inside of the cable. Secondly, the user is dealing with ready-made holes, oriented to work with specific wire sizes - this saves him from the troublesome preparation of the tool for working with a certain material format.

What is a crimper for?

The stripping of the cable is carried out as part of the general installation activity, the result of which should be the formed connection. That is, removing the terminal is a preparatory operation before further bringing together either two wires or connecting a cable to the device. To perform this procedure, the bare core must be in the form of a solid rod, in which individual antennae will be included. In such work, a crimper is useful, which will allow you to fit and correctly clamp the electrical sleeve onto the end of the cable. Typically, a wire stripper is supplied in the same kit as a crimper, as they complement each other's function, saving the technician time.

Wire Stripper Manufacturers

Specialized devices for working with wires are widely represented on the market. In particular, under the KNIPEX brand, wire cutters, tongs and repair knives are produced, designed specifically for removing insulating layers. Many manufacturers successfully combine several functions in such devices. Thus, the stripper WS 04B "КВТ", in addition to stripping the wire, also allows you to crimp end sleeves. Models from manufacturers SHTOK and KRAFTOOL by default can handle cutting thick wires - in this regard this product can also be called universal. For the most part, new models are reliable and highly ergonomic, but there are other nuances that should be considered when buying a tool.

How to choose a wire stripper?

Experienced electricians note that it is best not to count on the benefits multifunction devices with wide ranges of diameters available for cutting, and give preference to specific narrow ranges. For example, for basic needs, models that work with cables with a cross section of 0.05 to 10 mm 2 are suitable. If you need a professional device that can work in a wider range, then it makes sense to choose a wire stripping tool among universal models. At the same time, it is worth considering not only the size available products, but also the type of material of manufacture - it can be twisted pair, etc.

Conclusion

A feature of electrical work is the high risk of electric shock. Of course, it is not present in every workflow, but for those who need special tool for stripping wires, it is worth considering this aspect. Work in conditions high voltage in the cable should only be performed by devices with a dielectric coating. Typically, 1000 V rated stippers are produced with this sheath. The same safety requirements should apply to pliers, cable cutters, and crimpers. Also, do not forget about the rules for operating electrical tools, which, among other things, are aimed at ensuring a high-quality result in installation.

Catching up on petty repair work in the house, you often have to deal not only with wires, but also with cables. Therefore, the question arises: how to properly strip the wire from insulation? There are differences between a wire and a cable, for example, a wire is one conductor, which may not even provide for the possibility of stripping the insulation (bare wire), while a cable is a whole network of current carriers that do not touch each other, covered with a common layer - an insulating sheath. In fact, there are always several wires inside the cable. Stripping is sometimes required, both individual conductors and all conductors in the cable. Often have to shoot a long segment upper shell(isolation). That's why you can't do it with just your hands.

The types and arrangement of wires and cables have already been repeatedly discussed in articles on this topic. For example: "", "", "", etc.

As a rule, a wire is a conductor (rigid or flexible) covered with PVC (polyvinyl chloride) or rubber insulation. Insulation can be one layer, and maybe several. Sometimes a silk braid acts as additional insulation, sometimes the conductor part is covered with an insulating varnish.

How the cable is arranged is already written a little higher. What is technically considered a cable is often colloquially referred to as a wire, and stranded wire may be referred to as a cable. Polyvinyl chloride, rubber and other non-flammable dielectrics are used as insulation for wires and cables. They protect the wires from a short circuit between themselves, contact with a person and from fire.

Sometimes the conductors of stranded wire envelop quite dense layer isolation, which can cause difficulties when stripping.

According to the type of conductor section, the wires are divided into two types:

- Single-wire (rigid). They are a conductor consisting of one solid conductor.

- Multiwire (flexible). They consist of several very thin wires woven together.

For successful stripping, you must use quality tool and observe the norms and sequence of work, otherwise, the wiring will quickly fail.

Tools needed for wire stripping

To properly and safely strip the current-carrying part of the wire from insulation, the following tools may come in handy:

- Side cutters.

- Assembly, construction, stationery or household knife.

- Electric burner.

- Pliers.

- Special cutters for thick cables or shears for metal.

- A vise or other holding device.

Stripper: its purpose and model variations

A stripper is a special device for stripping wires. Simple Models This tool is similar in principle to conventional side cutters. The blades are equipped with recesses of different radii, designed for conductors of different sections.

The semi-automatic manual stripper is equipped with two pairs of bladed jaws. When using it, the end of the cable must be placed in working area, close the blade handles and cut the insulation. Sponges at the same time remove it from the core. The stripper of this model is equipped with an adjustable stop, which allows you to fine-tune the section of the placed wire. In Russia, this tool is called KSI (insulation stripping pliers).

Some types of strippers perform several functions at the same time:

- pruned

- clean up

- Twisting the veins

A twisted-pair stripper is a clip with a built-in blade that looks like the blade of a utility knife.

After equipment repair or electrical network, make sure that there is not a single bare area left.

Firm "Knipex"

The tool for stripping and cutting wires must be of high quality, in accordance with the requirements of the state standard. German firm Knipex makes time-tested, reliable wire stripping tools. Some of them are tested at 10,000 volts at +70 and -25 degrees. Therefore, there is no doubt about the reliability of the products of this company. Among other tools with which the wire is cut, the main ones can be distinguished:

- Combination pliers

- Knitting pliers

- Clamping pliers

- wire cutters

- Tweezers

- Forceps

- Cable knives

Founded back in 1882, Knipex is today one of the most well-known manufacturers wiring tool. Every day, 45,000 units of this company's products are sold. About a hundred countries of the world cooperate with it. And in our region, it will not be difficult to get a Knipex tool.

Wire or cable stripping process

Most often, wire stripping is done using side cutters. Sometimes cutting wires is accompanied misuse side cutters, which complicates the work and leads to damage to the current-carrying part of the wire. To remove the insulation, it is important that the cutting parts are directed in the direction opposite to the movement of the tool. Thus, the knives can cut into the insulation even with slight pressure.

If there are no side cutters or other special devices, you can take a knife, do not press the wire insulation with the cutting part of the knife and circle it around. If necessary, repeat until the protective layer of insulation is cut through and the point reaches the core. You can make an incision not across. and along the wire, then stretch the edges along the sides and cut off the sheath. This method is even considered by many to be better and safer.

When cutting, you can easily cut your hands, so be extremely careful.

How to cut outer insulation with a heeled knife video

When removing the outer layer of insulation, try not to cut it with translational movements (reminiscent of sawing). You just need to push it with the sharp side of the knife and slowly turn it. Do not use force. When the work is done, inspect the stripped ends of the conductor. There may be cuts or breaks in the current-carrying part of the wire. This end of the wire is not suitable for further use. It needs to be cut off and redone. If this is not given due importance, over time a dangerous situation may arise. As a rule, the damaged part of the wire core in the future, during operation, breaks off. In the future, it will be necessary to look for the place of damage to the cable, and this place, as a rule, will be hidden by insulating tape.

Sometimes it is not clear how to strip the wire, especially when it is too thin, and even stranded. There is one trick.

- Take an old razor blade.

- We break it and take one half of the blade.

- We fix the wire using a vice or clamps. You can use the table lamp clip.

- Cut the insulation along the conductor.

- We make neat cuts across the section, trying not to touch the conductor with the blade.

- We bend the cable so that the notched edges slightly part.

- We cling to the incision with a fingernail and pull the insulation from the core.

Stripping wires is a painstaking job that requires patience.

Mistakes often occur when stripping wires. Typical errors of stripped wires are visible in the figure:

Thin wires break very easily. Therefore, it is necessary to clean the insulation from them very carefully.

Stripping the insulation of thin or winding wires

With a conductor thickness of 0.2 mm, optimal way stripping, there will be a mechanical option. To do this, we need a knife or sandpaper, preferably a fine grain section.

The paper needs to be bent with an abrasive inward and a wire is inserted into the bent sheet, slightly pulling it and pressing it with your fingers. The procedure must be repeated until the enamel is completely peeled off.

When using a knife, it is necessary to put part of the cable on a hard surface and scrape off the varnish by scrolling the wire in a circle until the enamel is scraped off the conductor. So, cutting the wire is not a complicated process and does not require an electrician's diploma.

If the cross section is thinner than 0.2 mm, another method will be required, since mechanical results will not work, it will only damage the wire. In this case, it is worth mastering the thermochemical cleaning method. We will need a soldering iron and PVC insulation.

We put PVC on the table and heat the soldering iron. In a hot state, we drive them through insulation. When heated, chlorine will be produced, separating the enamel.

For tinning the wire during thermochemical treatment, you can take an aspirin tablet, lay the wire on it and run a soldering iron over it in the same way.

In addition to the fact that the cross section of the wire is so thin, inside it has many strands twisted into one conductor. Therefore, the use of this method requires accuracy and skill.

Power cable stripping

Power cables are mainly used for laying a conductor to powerful equipment and switchboards. How to remove the outer layer of cable insulation?

- Slowly cut from the end along the cable insulating layer but not very deep.

- With the help of pliers, we pull out one core located inside.

- Cut off the remaining piece from the outer insulation.

- We split the wires.

Before you begin this work, think carefully about how much insulation you need to strip. It is better to cut with a small margin. Having exposed a piece that is too long, you can always cut off the excess. Use a cambric to better position the cable inside the instrument.

When working with electricity, never neglect the need to exercise caution. Even if you have stripped the wires many times, remember that any cut in the insulating layer is a potential threat to the cable and wire.

And finally. Various tool for stripping wire insulation and how to use it video.

Hello everyone! Today will be small review on my coveted tool, a cable stripper. In work, situations often arise when you cannot normally clean the cable with an ordinary knife, or it will be traumatic for your hands (I cut my fingers more than once when my hands are covered in oil and dirt) and because I work in production, every second of downtime counts, therefore the work must be done as quickly as possible and not always with high quality (damaged cables, they change every week in the PPR). Of the many devices, I chose this particular tool, because I considered that it was more convenient for me. More about everything under the cut.

Specifications

Length: 170 mmMax blade length: 7mm

Handle Material: Plastic

Blade Material: Bearing Steel

Stripping cable diameter: Ø 8 – 28 mm

Appearance

The knife is delivered in a blister pack.C front side the name of the tool is written in large print, instructions for use are located on the back side and that's it available species tool from this manufacturer. There is no name of the manufacturer on the packaging, apparently they are made for third-party companies that make their own packaging and stick their nameplate on the knife.

All types of tools

The tool itself has a corrugated plastic case, with a recess for a sticker of any company. On top is a spring-loaded bracket with an additional knife blade on it, with two cutting sides. The knife comes with a protective cap to avoid accidents.

One side is a regular knife with double-sided straight sharpening, for stripping wires or cutting off excess insulation.

The other side is made in the form of a hook, has inside cutting edge. Designed for stripping cable insulation.

Knife blade thickness.

By comparison, the thickness of the blade of a conventional construction knife.

To perform the main function, i.e. stripping the insulation from the cable, a blade is installed in the knife handle, which rotates around its axis, depending on the actions performed. The brace is very strongly spring-loaded, has a protrusion for pulling it with your thumb, but does not have any notches (with dirty, oily hands, it will be hard to pull it back). There are notches inside the bracket to protect the cable from slipping during cutting.

The blade is adjustable with the help of a metal wheel, which is located at the bottom of the knife. Adjustment is necessary to adjust the cutting depth, because each cable has its own insulation thickness. The main thing to remember in this matter is that it is better to undercut than to cut.

The blade is bigger.

The knife feels pretty good in the hand, but I wouldn't mind the rubberized parts.

There are some imperfections in the plastic molding on the sides. But for a tool that will soon find itself in a dirty and dusty workshop, this is not a problem.

Now let's take a look and see what's inside.

We twist four screws around the perimeter of the case and cut it in half.

A spare knife immediately catches the eye, which is not mentioned anywhere.

To hold the bracket there is a huge spring.

The mechanism for lifting the blade is also a little regrettable. Plastic carving, well, Christmas tree sticks. And only after parsing the knife, I found out the reason for the tight movement of the adjustment wheel. The blade of the knife was not set all the way, not in the center. In places, traces of grease can be observed.

Working with the tool

The first half of the work will be done at home.I take the only cable found on the farm.

I try to clamp it with a bracket, but nothing really works, because the cable is 6 mm in diameter, and the tool only works with cables from 8 mm in diameter. Therefore, we can safely say that this is not a tool for the home.

But, the cable can be stripped using an additional knife, which is located on the bracket. Cut the insulation with a hook, without damaging the wires.

With the flat part, cut off excess insulation, or the wire itself. Then clean up the ends for further work.

I will deviate a little from the tool itself and tell you what you can use in everyday life.

Here is such a mini tool, consisting of a clothespin and a sharpener blade. In order not to litter the main topic, everything is under the spoiler.

Clothespin cleaning

Part two, work.

At work, the main difficulty arises with damage to the cables in the track chain. Either the cable cracks and shorts due to the aggressive environment, or the suspension comes out of the guides, falls, breaks and the cart chews the cables under the wheels. Basically, the track breaks down in places of increased accumulation of oil, dirt and water, so stripping and connecting the cables turns into something else.

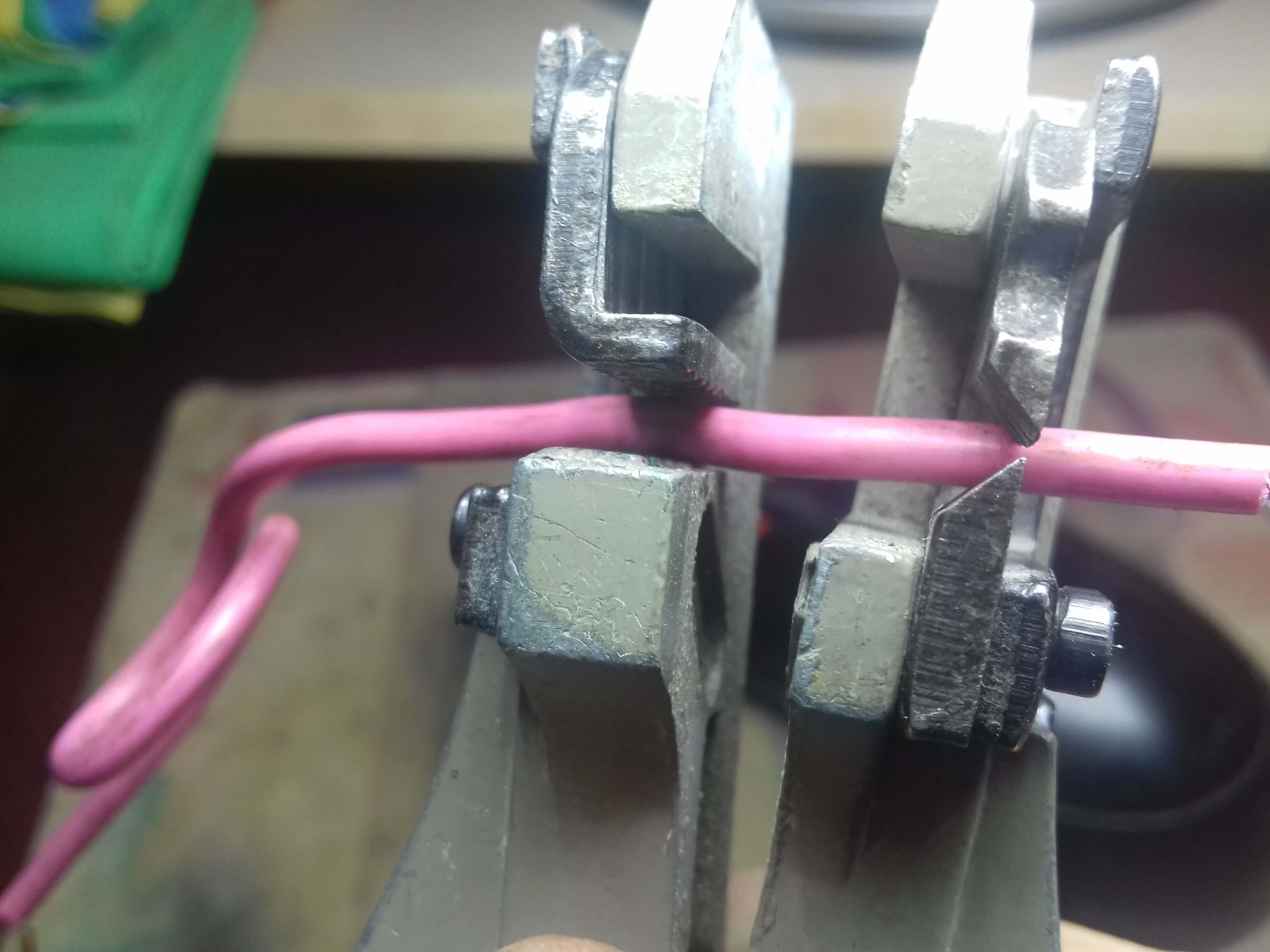

The photo is far from best quality, but what are.

For experience, we take a cable with rubber insulation, by eye somewhere 4x10, diameter 20mm. We clamp the bracket and adjust the blade.

Now we take the tool to the distance we need for stripping and make circular movements, the more movements, the better the cut.

Then we stop and cut along the cable, it takes a lot of effort to cut such insulation. The knife blade at this moment will automatically turn in the right direction.

We tear off the insulation and then we clean the ends of the wires.

Also, if the cores inside the cable are damaged, or the insulation is damaged, it is possible to cut out part of the insulation on any part of the cable and re-power, insulate the damaged area.

When there is not enough turning radius for cutting the cable, a knife with a hook helps out.

During the work shift, the tool rescued me several times. It is very convenient to clean the cable with double insulation and screen, cuts everything completely.

Outcome

I understand that not everyone will take something from home to work, because the employer must issue the right tools. But for me, the main thing is convenience in the process of work, because it’s enough to waste precious nerves on working with a clumsy tool.As for this knife, I can say that the idea is great, but the implementation let us down a bit. Too much plastic where there shouldn't be. In the future, you can replace the plastic thread of the adjustment wheel by mounting the nut and come up with something with the conical part where the knife blade rotates, because when stripping the cable, pressure appears on the edges of the cone.

There are no complaints about the blades and knives, the material is quite durable. It fulfills its role, cuts insulation and cores into a light one. You can only find fault with the quality of sharpening, but this is not a katana)

The plans are to find a replacement for the Soviet megaohmmeter and falling apart indicator screwdrivers.

Thank you for reading)

The product was provided for writing a review by the store. The review is published in accordance with clause 18 of the Site Rules.

I plan to buy +21 Add to favorites Liked the review +53 +96When carrying out any electrical work, regardless of whether new electrical wiring is being used or an existing electrical network is being repaired, it is necessary to make wire and cable connections. It doesn't matter which core you need to connect, aluminum or copper, in any case, we need a tool to strip the wires. Depending on how the insulation of the wire cores is arranged - it is covered with a layer of varnish or has a plastic sheath - in each case it may be necessary various techniques its removal.

Arrangement of wires and cables

How to properly strip a wire can be understood when you know exactly how it is arranged, what materials it is made of, and what it is intended for.

Let us immediately define that a wire is one or more strands of an electrically conductive material (copper, aluminum, etc.), on top of which a dielectric sheath (phase insulation) is made. The cable consists of two or more wires covered with a common insulating sheath (belt insulation), which can be made in several layers, depending on the functional purpose. But a dielectric is a substance that does not conduct electricity, it is also called an insulator or insulating material.

For the manufacture of phase and belt insulation, dielectric substances are most often used in the form of various polymers, such as:

- polyvinyl chloride (denoted by the abbreviation in the marking of wires - PV);

- polyethylene high pressure(PP);

- (PF);

- some others.

The application of a polymer sheath to metal conductors is carried out on specialized equipment by extrusion. Also, wire insulation is made from silicone rubber (KG), rubber, impregnated cable paper, in the form of a braid of fibrous materials, and many other dielectric substances. In addition, along with insulation, protection against mechanical damage is used for cables that are laid in the ground, and open way- in the form of an armor shell (B), made of lead, aluminum or a thin steel strip wound on a cable, covered with a layer of bitumen.

Thus, depending on the design of the dielectric sheath and the material from which it is made, it becomes clear that each type of cable will require a different functionality a tool capable of qualitatively removing insulation.

Purpose of wires and cables

How to remove the insulation from the wire so as not to damage it also depends on understanding what it is intended for and what function it will perform in operation.

Yes, by functional purpose wires and cables are divided into:

Depending on their functional affiliation, they all have significant differences: the copper wire of a telephone wire has the largest cross section of 0.5 mm2 and thin insulation, and the wire of the same copper of a power wire up to 1 kV starts from 1.5 mm2 and must have a thickness insulation, which is guaranteed to exclude the possibility of electrical breakdown.

Therefore, in order to qualitatively strip the wires from insulation and to accurately remove the sheath from the cable, it is necessary to use tools and devices that differ in functionality.

There are many ways to strip wires. Hand tools, which are used to strip the insulation from the cable, can be divided into:

If everyone can handle the first category of a cleaning tool, then for the second group some experience and skills will already be needed, but the third category professional fixtures, which makes it possible to produce simple work, and removal of insulation from special cable, will already require certain knowledge and practice in work.

Simple cleaning tools

Simple or improvised means that can be easily removed from insulation include conventional tools, which are in every home workshop.

Here, in the first place, of course, is the knife, as the most commonly used tool for removing insulation in everyday life. The main requirement for knives for cutting cable products is relatively small size, a short and strong blade, and it also does not hurt to have the handle insulated. Suitable stationery and any construction knives. But even in this category there are special knives made taking into account the specifics of the work - they have a thick dielectric handle and a short, durable blade. special form you can always buy them at hardware store for the sale of electrical products or tools.

Here, in the first place, of course, is the knife, as the most commonly used tool for removing insulation in everyday life. The main requirement for knives for cutting cable products is relatively small size, a short and strong blade, and it also does not hurt to have the handle insulated. Suitable stationery and any construction knives. But even in this category there are special knives made taking into account the specifics of the work - they have a thick dielectric handle and a short, durable blade. special form you can always buy them at hardware store for the sale of electrical products or tools.

Power wires of small cross-sections can be stripped using sharp wire cutters or side cutters, but this will require accuracy and certain skills so as not to bite the core without calculating the effort.

It is best to remove polyethylene insulation from simple telephone wires by heating them with a soldering iron tip, since the insulation melts easily, and thin copper wire it is not damaged. It is quite difficult to do the same operation with a knife and not cut the copper wires without experience.

You can clean the varnish coating of the copper conductor with a fine sandpaper, as well as heating the wire section with a soldering iron on an acetylsalicylic acid tablet, while you can also immediately tin the cleaned place of the future contact, eliminating the possibility of its oxidation in further operation.

Semi-professional tool

The semi-professional category includes:

- stripper for removing insulation from wires;

- manual adjustable stripper for external cable insulation;

- dielectric pliers for stripping insulation;

- semi-automatic stripper with cutting function;

- nail polish remover;

- stripper for coaxial cables.

All of the above tools for stripping insulation have a number of significant advantages, such as:

- affordable price;

- not very complicated and reliable design;

- simple operation.

Therefore, after carefully reading the instructions for use and having a little practice, everyone will be able to master the skills of working with such a specialized tool.

The functionality inherent in this category of tool will make working with cable products less time-consuming and of better quality. Thus, the removal of the belt insulation of the cable with a stripper for external insulation is guaranteed to leave the phase coating of the wires unharmed.

Professional tools and special fixtures

Progress does not stand still, therefore, in order to increase labor productivity and High Quality works on sale there is a category of tool designed and created by professionals. It is used both for ordinary tasks and for special types work of particular complexity.

As a rule, professional tools are capable of doing several operations at once. For example, to make a communication connection of two computers with a twisted pair, consisting of 4 pairs of single-core copper conductors with a cross section of 0.5 mm2, it is necessary to attach plugs to the ends of the network cable. This is the operation that the crimper performs, managing to clean the insulation on all eight wires at once, crimp them and fix the plug at the end of the cable in one click.

Keep in mind that no knife can replace a real wire stripper when it comes to high-quality electrical work. Try to choose and use only professional tools and specialized devices in your work.

One of the most indispensable tools of an electrician installer is. When the number of connections is calculated not by one dozen, but sometimes even a hundred conductors, the removal of insulation becomes a tedious nightmare that takes up the lion's share of time. To help in this difficult work, special devices have been developed - strippers. In this article, we will look at the main types of this tool, provide our own opinion on which one is better to choose, and also tell you how to use a stripper to strip wires.

Types of insulation strippers

Pliers for stripping insulation differ both in principle of operation and constructively. There are manual, semi-automatic, automatic strippers. All of them are united by the principle of operation, the incision of the insulation and its removal from the conductor to a certain length.

Manual pullers have the simplest mechanism of operation. In appearance, a mechanical stripper is similar to pliers, only on the sponges there are additional sockets with blades under different section current-carrying conductors. This type of tool is suitable for stripping wires with a cross section of not more than 6 mm2, as well as for crimping lugs (some models allow). It is not difficult to work with a manual stripper - you just need to install the core in the nest, press the handles (there will be a girth) and make a circular motion, as a result of which the insulating sheath will be removed.

Semi-automatic puller models are even easier to operate. The mechanism is more advanced, so there is no need to independently scroll the stripper around the wire. It is enough just to fix the core in a suitable socket and press the handle. Also, many models of semi-automatic pullers allow you to cut wires and crimp lugs.

Automatic stripper is already professional tool to strip the insulation from the wire. Its difference from the semiautomatic device is the independent determination of the wire cross-section, due to which the stripping process boils down to the fact that you just need to install the core in the socket and press the handle. Automatic strippers are the most expensive, but can also strip multiple wires at the same time, strip the core of a wire, strip flat conductors, and more.

Which stripper is better to choose

Speaking of small electrical work around the house, it is better to choose a manual cable stripper, which will allow you to peel off the sheath from the cores, with a cross section of up to 6 mm.kv. Mechanical models are inexpensive, about 400 rubles, and for home electricians they will be quite suitable in terms of functionality.

Electricians whose life is directly connected with the laying of electrical wiring, it is better to choose a semi-automatic or automatic stripper. The price of the tool starts from 1000 rubles, for a quality puller you will have to pay even more. But if you take into account how much easier and most importantly to speed up the wiring, you can not hesitate to give preference to the improved mechanism.

Rules for using the tool

stripping veins

Consider the instruction manual using the example of a Chinese semi-automatic stripper that has been serving faithfully for more than a year. This model is absolutely not whimsical and easy to maintain.

The cutting element is a pair of plates with a dimensional notch under different diameters strands, as shown in the photo:

By placing the wire in the grip of the tongs, we leave the wire with a length for stripping the insulation, behind the knives, as shown in the photo below:

Holding the wire, we reduce the pliers, squeezing the handles. The knives converge to cut through the insulation, and the thrust jaws compress and pull the wire back. As a result, the insulation is removed from the wire.

The instruction manual for the manual stripper is provided on the video:

An important point when using a stripper is to choose the right size of the cut in the knives, if you make a mistake with the diameter, the soft conductor will be damaged and may even break off at the stripping site. Also, do not capture a large length of conductor insulation, it is better to divide into several operations of less. With sufficient skill, stripping the insulation with a stripper takes less than a second, and the work itself ceases to be boring and routine. Therefore, the purchase of this device saves time and money, as well as the strength of the electrician. In addition, the tool pays off with a vengeance.