Glass frame partitions - excellent sound insulation, strength and quality

Interior walls of a frame house

First of all, let's deal with the axioms. Internal walls frame house should be divided into two types - carriers and partitions. The first are part of the frame of the building and serve necessary elements rigidity. The latter separate the premises and only partially stiffen the future home.

You will have to plan the load-bearing walls even at the foundation level. Usually under them use the same reinforcement as under the perimeter. Partitions can be erected already in the course of construction. Rigid functions are rarely assigned to them, but they have them in mind.

We put the load-bearing walls of the frame house

So, we will start the conversation with the load-bearing walls of the frame house. They are placed together with the outer ones. Why are load-bearing walls needed? The answer to this question is obvious. Far from always external walls of your home are able to withstand and qualitatively share the load that the roof and upper floors create.

For example, a one-story building with shed roof with an area of 3x6 meters can easily do without internal load-bearing walls. But to build a house of 6x6 meters without them will not work. The rule here is simple. If you can lean on the outer walls with both ends of the genital lags (and not suffer from their deflection!), Then you do not need load-bearing ones. Otherwise, you will have to install them. We would not recommend hanging the floors of a frame house (simple wooden logs 200x50 mm) more than 4 meters (maximum 4.5 meters). Of course, this does not mean that the room cannot be larger than 4x4 m. One of the walls can be of any length, but the second will be limited to the length of the floor lag.

What material do we usually make the load-bearing walls of a frame house from? A board of 200x50 mm is usually used. The same one that goes on the outer walls. It is not worth making load-bearing walls from boards of smaller thickness.. They are placed not on the floor, but on the board of the first crown.

The alignment of the load-bearing walls and the installation of the jibs (read) is carried out at the construction stage of the floor where it is located.

The wall is filled with noise-absorbing material (read) or insulation. In the future, you may want to heat part of the house, and not the whole. Therefore, load-bearing walls can become a real barrier to cold. However, someday we will tell you about the conservation of a house or individual rooms and describe in detail all aspects of such events.

Is it possible to fill a load-bearing wall only halfway? Yes. Just be careful with the fixation of mineral wool. Put more brackets on the top and around the perimeter than on the side walls. Cotton wool will not be subject to lateral friction and the temptation to "fall off" will be greater. Fixation brackets should be placed every 10 cm.

Do I need to use a membrane or other fabric in load-bearing walls? We strongly recommend doing this due to the improvement in noise isolation. If the house is heated on both sides of a load-bearing wall, then cheap tar paper can be used. It costs a penny, but it "copes" with sound and dust from cotton wool no worse than a membrane. The smell from it will disappear in just a week (completely), do not be afraid of it. Tile paper or membrane is fixed with paper clips from a construction stapler.

An inch board (100x25 mm) is put on top of the paper or membrane. The interval between them is chosen according to the finishing material. For drywall or lining, they usually make 60 cm between the middle of the boards. Be sure to put the bottom (floor) and top (ceiling board), regardless of the interval.

Attention! I strongly recommend to remember, but it is better to write down and photograph this crate. You will need to screw in a screw or hammer in a nail, remember your work and you will not break into the "emptiness". If you know where you will need to make wood reinforcement, it is better to fill the boards there now (for example, for the top kitchen cabinets or mirrors in the hallway).

We put partitions in a frame house

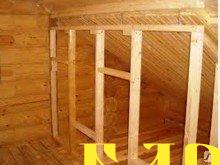

So, how to correctly place room partitions in frame house? There are two approaches here. It is impossible to distinguish between them the right one. The first is to create load-bearing structures between the floor joists and install vertical boards on them, which will become the wall frame. The second method is more simple. If you decide to make the floor, as we suggest (read here), then the wall racks can rest on the floor itself or a board screwed to the floor (for example, 100x25) projected onto the floor.

Expose the racks so as not only to get comfortable and correct rooms, but also to strengthen the frame of the house. For example, if your building has two floors, then the interior walls can significantly reduce the fluctuation of the second floor floors. This is a pretty powerful tool. skillful hands builder.

Usually builders draw rooms on the floor, and then put racks according to the drawn projection.. So you can appreciate the convenience of the doors and the volume of the rooms. Remember that such “estimates” always visually reduce the volume of the resulting rooms.

What is worth making interior partitions in a frame house? Usually, a 100x50 mm board is used for this. It's definitely not worth it. Keep in mind that the wall will grow interior decoration. Its thickness in the most successful scenario will be 17 cm or more (board 100x50 + two crates on each side 100x25 + drywall on both sides of the wall 12 * 2).

After completing the installation of windows and doors, you should take up the installation of interior partitions.

In frame houses, it is allowed to choose from several different types of partitions:

- Frame-sheathing.

- Single plank.

- Double plank with soundproofing.

Consider the design and installation of a frame-sheathed partition, as the most economical and easy to assemble.

Naturally, you should not throw away brick partitions for frame houses, however, this option will require a full-fledged strip foundation. And when the house is made of wood, it is recommended that the partitions be made of the same material. However, the final decision remains with the owner of the house.

Required tool:

- nail puller;

- a hammer;

- nails;

- hacksaw for wood (electric jigsaw);

- a ruler or, if simpler, a flat two-meter rail;

- construction level;

- roulette.

- simple pencil.

Necessary materials:

- edged board for the installation of racks (vertical) for the partition. Thickness 3 ... 5 cm, width - 10 cm or more. Please note that if joint supports are installed in the formation (including for partitions), then the width of these boards must necessarily correspond to the width of the main supports;

- Chipboard, drywall, plywood, fiberboard. In the latter case, due to the small thickness of the material, the walls of the partitions must first be upholstered with boards (not even tongue-and-groove) - this is an additional cost of money, time and effort;

- various soundproofing materials, for example, mineral wool, sheet foam, etc. If foam is selected, it can be fixed using special “ liquid nails» for this material.

Installation of frame-sheathing type partitions

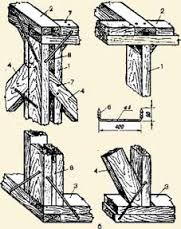

1. Frame formation:

a) attaching boards 50 mm thick to the floor and ceiling, in which grooves 25 mm deep are provided (the width of the boards is equal to the thickness of the partition racks). In the lower and upper trim, the grooves must be installed opposite each other (distance less than 500 mm);

b) side racks are installed directly on the load-bearing walls with an interference fit between the strappings. All other racks are installed in the strapping grooves;

c) the length of the uprights should provide a slight tightness so that the upright is assembled not just with the help of muscular strength, but with a slight tension (it is allowed to tap a little with a hammer or mallet at the points where the end of the uprights are mounted into the strapping grooves when inserting the uprights into the grooves).

d) you can fix the rack in the groove using nails that are driven at an angle into the edge with inside. As a result, the nail enters the strapping boards at the partition. Nails must be chosen so long that it exceeds at least 2.5 times the thickness of the rack;

A frame house is essentially a box in which there are no rooms. And the final stage in the creation of the final project will be the installation of interior partitions. Interior partitions in a frame house are of two types:

- Brick.

- Wooden.

The latter are divided into three additional types of room zoning. In addition, each category has its own characteristics of design, installation and possible loading of shelves with mirrors on a vertical plane.

Varieties of interior partitions for a frame house

The option of erecting brick borders between rooms is of little demand. This is an additional load on the foundation, and it must be made according to a certain tape technology. If the house is made of wood, then the partitions are made of the same material.

Single plank partitions

Bars are stuffed on opposite walls, and tongue-and-groove narrow boards are mounted without the slightest gaps, very tightly from floor to ceiling, they are fixed with nails at least every 5 cm. This will be part of the interior partition in the frame house. Then another bar is attached, securely fastening the previous two parallels. Thanks to this fastening, the design is quite durable. But along with this, it does not have thermal and sound insulation.

Double board partitions

This is the more expensive option. At the initial stage, a type-setting frame is installed on the walls, consisting of boards 10 cm thick and wide. A plank is stuffed onto the floor, which allows you to mount intermediate bars. The frame is sheathed sheet pile boards on both sides, for which it received its name. And the void formed inside is filled with heat and sound insulating materials.

Frame-sheathing

As with any other design, the frame is installed first. It is formed from five-centimeter boards. This is a binding. Side partitions are fixed at the boundaries of the load-bearing walls. The partition is built from strapping and type-setting vertical boards. In order for the racks to hold securely, it is worth fixing them in the grooves with nails at a slight angle. The next step will be sheathing with facing material on one of the sides. With reverse side soundproofing material is fixed and the lining of the partition from another room is mounted.

What you need to consider when installing interior partitions in a frame house

The boards that are used for the construction of interior partitions in a frame house are not thicker than 50 * 100 mm, as the finishing of the walls follows. Remember that these structures must be limited on at least one side outer wall. Partition area 2 times more area floors, therefore, it is important to take into account the load (weight and thickness of the partition). When using combustible materials, for safety reasons, the partition should be at a safe distance from heating appliances. This is especially important to consider when installing frame partitions in the bath.

And in order to avoid unpleasant moments with this type of space zoning, please contact us. Our team can handle any task with high quality and at an affordable price.

The walls of a frame house consist of many beams. For many, it will seem that their installation is carried out in a chaotic manner. But this is absolutely not true. There are rules and schemes according to which the assembly is made. Deviation from the norm is fraught with the most serious consequences.

Three mounting options

Solid construction device

For the assembly of such partitions, dried timber is used, with a thickness of 50 to 100 mm. As facing material suitable, chipboard, fiberboard or drywall. Between themselves, the timber is connected “in a quarter” and, for reliability, is fixed with spikes from 10 cm long. Fastening to carrier beam made with metal corners or a triangular bar. Fixation with a load-bearing wall is carried out in a more reliable way: by using a deformation groove or using long nails.

Advice. The length of the fastener is selected so that at least 50 mm of the fastener enters the load-bearing wall. For example, a frame stand with a thickness of 100 mm means a nail of at least 150 mm.

solid baffle

The walls of this type of partitions frame-panel house consist of vertically mounted boards 50x100 mm. For reliability, they are installed every 50-60  mm, and stability is ensured by the device of the upper strapping. The lower ends of the board are fastened into a pre-cut opening in the logs. The voids are filled with polystyrene or mineral wool and a vapor barrier material is attached on both sides. The frame is sheathed with gypsum-fiber plaster or drywall.

mm, and stability is ensured by the device of the upper strapping. The lower ends of the board are fastened into a pre-cut opening in the logs. The voids are filled with polystyrene or mineral wool and a vapor barrier material is attached on both sides. The frame is sheathed with gypsum-fiber plaster or drywall.

Shield panels

In this design, the boards that perform the supporting role are located relative to each other, at an angle of 90 ° C. The walls are assembled from several layers of stuffed boards, with a lining between each roofing felt or other material aimed at protecting against moisture and increasing the soundproofing effect. Depending on the number of layers, the board is selected required thickness: 30 mm - two-layer shield, 20 mm - three-layer. The partition is mounted in pre-cut grooves on the load-bearing walls, ceiling or floor. Finishing may be different, from sheathing sheet materials, before plastering with gypsum or cement mixture.

A little about insulation

In residential frame buildings, special attention is paid to the choice of this material. Good material contributes to the correct distribution of heat in the internal  space of walls, protecting them from premature decay and isolating unnecessary sounds. The heat insulator must be environmentally friendly. For example, vermiculite or ecowool. Expanded clay filling is allowed. Basalt wool used only with a double-sided vapor barrier. For residential buildings, as a heater for frame partitions, the most unsuccessful material is polystyrene foam. It is flammable and emits the caustic invisible gas styrene.

space of walls, protecting them from premature decay and isolating unnecessary sounds. The heat insulator must be environmentally friendly. For example, vermiculite or ecowool. Expanded clay filling is allowed. Basalt wool used only with a double-sided vapor barrier. For residential buildings, as a heater for frame partitions, the most unsuccessful material is polystyrene foam. It is flammable and emits the caustic invisible gas styrene.

Device type internal partitions chooses the owner of the house, if possible self erection or the amount of material used in the work. An important point there will also be a method of fastening: metal corners - a simpler option, cutting out a landing groove, requires skill and at least superficial knowledge of carpentry.

Imagine modern house impossible without interior partitions. They are made from various materials and with different technologies. We will tell you about how such interior partitions are arranged in a frame house.

Types of common partitions

In frame houses, it is customary to distinguish between several main types of such internal walls. It can be single plank, frame-sheathed, double plank and structures with high-quality sound insulation. The choice of certain varieties must be made depending on the purpose of a particular room. It should be said that frame-sheathing options are universal, they are easy to arrange, have an affordable cost and therefore are widely used today.

It is also possible to perform brick walls in frame-type houses, however, this invariably leads to an increase in the load on bearing structures. Therefore, we would not recommend you to make all internal walls from this material. The only exceptions are houses that have a solid strip foundation, which allows them to transfer the load to the ground in a quality manner. Wood, as a material for walls, is most widely used. It is environmentally friendly, a light weight and subject to correct operation can last for a long time.

We make partitions in a frame house

Mounting interior walls starts after installing all windows and doors. When using wood  vertical racks made of boards with a thickness of about 50 millimeters and a width of at least 100 millimeters. Such dimensions of the racks guarantee maximum strength, stability and durability of the erected structures. The completed frame can be sheathed with drywall or chipboard. You can also use fiberboard or plywood for sheathing the frame. In the event that the design is done in living rooms, then sheet foam can be used as soundproofing components, mineral wool boards and other similar noise and heat insulators.

vertical racks made of boards with a thickness of about 50 millimeters and a width of at least 100 millimeters. Such dimensions of the racks guarantee maximum strength, stability and durability of the erected structures. The completed frame can be sheathed with drywall or chipboard. You can also use fiberboard or plywood for sheathing the frame. In the event that the design is done in living rooms, then sheet foam can be used as soundproofing components, mineral wool boards and other similar noise and heat insulators.

Equipping frame-sheathing partitions

Technology must be followed exactly construction works and a certain sequence of finishing. So, the frame is initially made, for which boards 50 millimeters thick are attached to the ceiling and floor. This will allow us to perform the so-called strapping, into which the supporting racks are subsequently inserted. In this case, the side extreme racks must be attached to the walls. Such frame elements should be inserted into the grooves made with little effort. They are fixed with nails or screws. To increase the rigidity of the structure, it is possible to arrange horizontal jumpers between the vertical posts.

It should be remembered that the frame is the basis of the entire structure. Therefore, the quality of its manufacture should be approached with all responsibility. After completing work with load-bearing elements and walls, you can begin to sheath them decorative material. This work is carried out on one side, after which noise is laid inside and thermal insulation materials. Only after that proceed to the sheathing on the opposite side of the partition.

It should be remembered that the frame is the basis of the entire structure. Therefore, the quality of its manufacture should be approached with all responsibility. After completing work with load-bearing elements and walls, you can begin to sheath them decorative material. This work is carried out on one side, after which noise is laid inside and thermal insulation materials. Only after that proceed to the sheathing on the opposite side of the partition.

Conclusion

The arrangement of partitions in a frame house is not difficult, so each homeowner can perform this work on one's own. We recommend using frame-sheathing technologies using lumber. It will also be necessary to select high-quality noise and heat insulation materials, which will increase performance characteristics completed interior partitions.