Internal reinforcement masonry. Ensuring the spatial rigidity of buildings. Repair for main cracks

Sometimes walls, even those made of brick or reinforced concrete slabs, fall into disrepair. And there can be many reasons for this: fire, time, the premises were not inhabited for a long time, soil subsidence, design errors, the appearance of an unplanned load. The degree of damage to the walls is different, it depends on it the course of work necessary for their reconstruction or strengthening.

Gain Features

Before starting work on strengthening and repair work, it is necessary to establish the degree of damage and, only then, proceed to work.

There are four levels of damage:

- weak (damaged up to 15% of the wall surface);

- medium (damaged up to 25% of the surface);

- strong (damaged up to 50% of the surface);

- destroyed walls - more than 50% damage.

Advice. To determine the level of wall damage, or the rate of crack movement, you need to install gypsum beacons (for internal walls) or cement (for exterior walls).

Cracks on the outer walls can change their width depending on the season: they narrow in winter and widen in summer.

Beacons are installed according to the following technology: the surface of the wall where the beacons will be installed is cleaned and moistened. Strips of cement or gypsum are applied to it with a spatula (thickness 10 * 4 * 0.8 cm).

Advice. The thinner the beacon, the more accurately you can determine the speed of the crack. It is also better to install several beacons along the length of the crack.

After the lighthouses have dried, they are marked: a line is drawn along the lighthouse with a pencil, an observation notebook is started, and the date of installation of the lighthouse is recorded. To complete the picture, it is necessary to observe lighthouse observers every day. With further growth of the crack, the beacon will be damaged (torn), and with further observation, you can find out the speed of its movement.

Strengthening with a strong foundation

The appearance of cracks did not arise due to design errors or improper foundation laying. There are several ways to fix them.

First way. Crack depth less than 5 mm. In this case, fill cement mortar or warm plaster with polystyrene. First, the crack is thoroughly cleaned and moistened, after which it is filled with fresh mortar.

Second way. Depth of cracks more than 5 mm. For good result metal staples are used.

Strengthening brick walls in this case occurs in the following order:

- the crack is cleaned and moistened;

- poured with a solution of cement and sand;

- along the crack at some distance from it, holes are drilled 11 cm deep, 2 cm in diameter, step - 15-20 cm;

- the strobes serve as the base of the brackets, the depth of which is 4 cm and the width is 3 cm (the strobes are attached with a mixture that was used to close the crack);

- reinforce the staples.

Important. In order for the staples to serve for a long time, they must be processed and plastered. The same applies to gratings to reinforce walls.

Third way. For deep or through cracks, metal jumpers are used (they are fixed rigidly with bolts on both sides of the crack), and then the damaged area is replaced.

Since the metal conducts both current and cold well, it is necessary to insulate the walls with restoration work.

Reinforcement with strands

They are used if the verticality of the walls is violated, followed by their collapse. For the screed, round fittings (with a diameter of 25-30 mm) are used, they are screwed either to each other in the corners, or to strobes that are installed at the joints of the walls (the second option is more reliable).

If the damage to the walls is stronger, then install clips from various materials:

- reinforced;

- reinforced concrete;

- compositional;

- steel.

This is what heavy looks like

The principle of strengthening the walls is approximately the same: first, metal corners are installed and attached to the walls, then a grid is made of various materials. The cells are attached to the wall with anchors (10-12 mm), or the joints are welded, or fastened to a metal mesh. After that, the mesh must be plastered with a cement mixture.

Reinforced concrete structures can also be reconstructed or strengthened. Such works are of two types: restoration of individual sections, or replacement of the protective layer (in whole or in part).

For partial restoration, cement putty is used, having previously cleaned and moistened the surface. If it is necessary to carry out a large reconstruction or replacement of the protective layer, it is better to use shotcrete. If the structure is load-bearing, then the thickness of the protective layer is increased to 3 cm, and if not working, then up to 2 cm.

Important. Before starting restoration work, it is necessary to clean the protruding fittings from rust.

Strengthening the opening in the wall - process features

We strengthen the opening

The piers are reinforced by disassembling a part of the masonry and replacing it with a new one, or inserting a steel plate or a reinforced concrete gasket slab. To carry out these works, support beams are installed in the opening strictly vertically.

Then, a part of the masonry is carefully disassembled, or a steel or reinforced concrete slab is inserted. Gates are installed in the recess and gates are attached to them, to which, in turn, a steel plate or reinforced concrete slab is attached. After its installation, it is covered with cement mortar. After complete drying of the latter, the supporting structure is disassembled.

The end of the work is the complete restoration of structures.

You can see an example of strengthening dilapidated walls with rolled metal in the video below. We definitely recommend doing this.

We will be grateful if you press the buttons social networks. Let your friends also be able to get acquainted with the above technologies.

Have a nice day!

Quite often, for buildings with brick walls, such a complex of works as repair or complete restoration is required.

Stitching

Gain brickwork in this case, it can be done in several ways, which depends on the causes of deformation, the nature of the damage.

The main reasons for such deformations lie in the following:

- Structural errors: insufficient depth of the foundation of the building; uneven settlement, the appearance of stresses in the walls, the discrepancy between the existing calculated loads, any deformations of beams and ceilings; the use of warm solutions; violations in the spatial rigidity of the composition;

- Poor operation: subsidence of the foundation; waterlogging of the wall; leveling the mortar, in which it is driven deep into the masonry;

- Production errors: punching an opening with violations; lateral buckling masonry; improper plastering; poor-quality dismantling of floors; laying beams without the use of distribution plates;

- Design Bad quality: increase in the number of storeys without carrying out all calculations; improper redistribution of loads; lack of developments on the state of the soil in the construction sites.

At the same time, there are many ways to correct such deformations: jointing, re-laying, full restoration, strengthening of floors, beams, supports, increasing and redistributing the bearing capacity, and much more.

Methods and stages of work to strengthen the masonry

Stitching

Jointing of brickwork is usually needed when there is significant weathering of the mortar. This can greatly worsen the thermal and mechanical properties of the wall, reduce by fifteen percent bearing capacity.

At the same time, before starting work, all damaged seams are washed with water, then they are filled with fresh mortar and smoothed. After drying, you can start painting.

Jumper reinforcement

Quite often, work is required to disassemble or repair old brick lintels. If there are single shallow cracks, then they can simply be filled with a solution under pressure. However, in the case when the damage is large enough and threatens the integrity and safety, it is necessary to take measures such as dismantling the brickwork and its restoration.

Sometimes arched ceilings with ordinary and wedge-shaped lintels are simply reinforced with reinforced concrete beams, which are installed by the method of supply under the jumpers themselves.

Strengthening runs and supports

When cracks appear under supports, racks, girders, it is necessary to take measures to unload to the actual bearing capacity of the masonry itself.

To do this, install metal platinum or gasket reinforced concrete slabs which bear part of the load. In some cases, it is required to make a complete disassembly and installation of a new masonry.

Repair of weak spots

If there are cracks on the walls with a width of up to 4 mm, they can be restored by injection of cement mortar. With significant deep and through cracks with an opening of 4 mm or more in the damage zone, this section is re-layed. In this case, a brand 25 solution is used when dressing with an old undamaged masonry.

If the wall has a significant thickness, it is necessary to carry out work on its complete restoration (with through large damage).

Replacement of some sections

Reinforcement of masonry may require the replacement of rather severely deformed individual sections. These may be some places of the walls that have lost their bearing capacity, as well as deep cracks and chips that lead to subsidence of the wall section.

In order to make a replacement, install temporary fasteners above the deformed places. Damaged areas with defects are completely transferred using mortar grade 100. Masonry is carried out with full fit individual bricks.

To relay load-bearing walls without disassembling the floors, multi-tiered temporary fasteners are installed, which transfer loads from deformed sections. Such fasteners cannot stand for more than five days.

Before starting work, it is necessary to install unloading beams, which are laid from the side of the weakest sections. All vertical gaps are filled using a plastic cement mortar, and from above - with hard greasy cement. Having strengthened the areas, it is worth waiting until the solution hardens. Only then can finishing be done.

Reinforcement of piers

If it is necessary to strengthen the brick walls, the following types of work are performed:

- Dismantling of window and other openings;

- Temporary anchorages for outdoor scaffolding are being strengthened;

- Hanging of the higher floors is carried out in the case when the weakening is carried out on an area of more than 25 percent. At the same time, poles, piers, other elements are shifted, the necessary repairs are made;

- Masonry is dismantled, furrows are punched with a jackhammer, damaged areas are felled, which is carried out using a reinforced concrete clip;

- Construction of a special metal frame;

- Demoulding of all monolithic structures;

- Complete disassembly of all installed temporary fixtures;

- Plastering and subsequent painting of the walls.

Also, new masonry one brick thick can be laid, which is tied up with the old masonry every three to four bricks. At the same time, special grooves are made in front of the device for the reliability of the structure.

Complete refurbishment of walls

Strengthening masonry with reinforcing mesh

When strengthening brickwork, a complete re-laying of the walls is sometimes required. In this case, you first need to unload the wall, for which temporary fasteners and supports are installed on both sides, under the floors, a system of crossbars and racks with trays. After that, you can proceed to disassembly and full or partial re-laying, which is carried out on a cement mortar.

To increase the strength and load-bearing capacity, reinforcing wire mesh is usually used. Also, reinforcement is carried out using a reinforced concrete clip, which is laid directly on the masonry. After disassembly window openings quarters are beaten off, then reinforcement is installed, formwork along the perimeter of the opening, concreting is carried out. In order to improve adhesion, furrows are punched every three to four rows of brickwork. Their depth is different, it all depends on the degree of damage.

After the formwork is removed, the piers are plastered, for interior spaces a special layer is applied to the surface warm solution right on the plaster.

Also, a metal corset is used for reinforcement, for which the corners are cut down and in their place vertical metal corners are mounted to the entire height of the wall. Further along the surface, furrows are made with a depth of 2 cm at a distance of 30-50 cm. Metal plates with a width of 4-6 cm are laid in them. At the same time, they are welded ends to the corners. On the corners themselves, tubercles are welded in a checkerboard pattern.

In some cases, it is possible to use a metal mesh, the surface of which is plastered after work.

Improving the stability of the walls

Reinforcement of brickwork is carried out using strands of strip or square steel or using steel channels that are installed in the walls through pre-drilled holes.

After that, vertical plates are strengthened on the sides of the building, while the screed is produced by tightening the nuts at the ends. The final tension is produced using turnbuckles, i.e. couplings with internal double thread. This is carried out in the middle part of the entire length of the banner, which consists of two separate parts. A high-quality screed is provided only when there are no sags, and with a slight tapping, they all make a high-pitched sound, very clean.

Results

After all fasteners are installed, holes and cracks brick wall carefully close up with the help of the prepared cement mortar, shift especially weakened places. All metal parts fasteners after completion of work are painted with a simple oil paint.

Hello. The house is old brick, the hand does not rise to break - the parental house. The walls are cracking from top to bottom. We need to strengthen the foundation. Everyone recommends contacting a specialist, but where can I get one? What is it called? Which organization should I contact? Tell! Sincerely, Vyacheslav. Ivanovo.

Hello Vyacheslav!

The profession of the specialist you require is called a design engineer (do not confuse it with an architect). You can find such a specialist in a design organization that develops construction drawings. In addition, you can contact the construction organizations or teams specializing in the reconstruction of emergency facilities.

The main reason for the destruction you described is the uneven settlement of the foundation. The reasons for such precipitation may be different. The most common are local soaking of the soil, the appearance (intensification) of the heaving properties of the soil due to the rise in the level ground water.

The measures necessary in your case should be developed by a specialist based on the results of a full-scale survey of the state of structures and communications. But since your problem is not unique, the general principles for solving it can be highlighted even without examination.

The first step is to determine the root cause of the ongoing processes. Around the house there should be a waterproof blind area. Water-bearing communications should function without leaks - inspect them. You can assess the groundwater level by checking whether there is water in the basements of nearby houses (if your house does not have it).

If the cracks intersect load-bearing walls along their entire height, and especially if there are cracks that widen at the top of the wall, strengthening the foundation may not be enough. With intense fracturing, the full range of required measures is usually the following:

- Strengthening the foundation.

- Installation of window frames and doorways steel rolling corners and a strip in order to form steel clips around the piers between them.

- Installation of steel bands.

- Elimination of the causes that led to uneven deformations.

- Repair.

Strengthening the foundation is carried out by excavating the soil around the perimeter of the building, followed by pouring concrete. The need for reinforcing concrete, as well as the nature of its adhesion to the existing foundation, depend on the design and depth of the latter. In old houses, as a rule, the foundation was made of rubble concrete without reinforcement. Side surfaces such foundations usually provide good adhesion to fresh concrete. If the surface is smooth and the foundation is reinforced, a small undermining is performed under the base of the foundation in short sections (usually 1 m each) so that the concrete, when poured, gets under the foundation and can take the load.

Pouring concrete under the corner of an existing foundation

Framing openings will require the dismantling of windows and doors, which will necessitate repairs. If there is an internal load-bearing wall in the house, it is imperative to inspect the condition of the openings in it.

Framing the doorway in the interior bearing wall

The strands are made of steel cable, strip or reinforcement. If necessary, their tension is provided special device- lanyard or screws. Places and methods of installing strands, as well as the appropriateness of their tension, should be determined by a specialist.

Reinforcement of brick walls with steel strands

If there was no blind area or it fell into disrepair, it must be equipped. The recommended width depends on the properties of the soil and ranges from 1 m to 2 m. It is advisable to insulate the blind area and the basement of the walls. This will reduce heat loss and insure against heaving processes. The width and thickness of the blind area insulation must also be determined by a specialist.

At the end of the work in the first year, it is advisable not to finish the facades so that it is possible to observe cracks. In this case, gypsum beacons are placed on top of them, by which it is easy to see whether destructive processes.

An example of installing a gypsum beacon

Wide cracks should be caulked with a plastic concrete repair compound.

The full range of activities will be costly. Therefore, an accurate qualified determination of the required scope of work by a specialist invited to the site is very important.

Tkachev Sergey

Examination of stone and armo stone structures is carried out taking into account the requirements of SNiP 11-22-81 "Stone and reinforced masonry structures", as well as "Recommendations for strengthening the stone structures of buildings and structures".

Before the examination stone structures it is necessary to reveal their structure by highlighting the bearing elements. It is especially important to take into account the actual dimensions load-bearing elements, design scheme, assess the magnitude of deformations and destruction, identify the conditions for supporting beams, slabs and other bending elements on the stone structure, the condition of the reinforcement (in reinforced masonry structures) and embedded parts. The size and nature of defects, the presence of typical damage (chips and cracks) directly depend on the above conditions.

For strength determination masonry use tools and appliances mechanical action and ultrasonic devices. With hammers and chisels, by a series of blows, one can approximately estimate the qualitative state of the material of stone and concrete structures. More accurate data are obtained with the help of special hammers, i.e. mechanical action devices based on an assessment of the marks or results of impact on the surface of the structure being tested. The simplest, albeit less accurate tool of this type is the Fizdel hammer. A ball of a certain size is pressed into the impact end of the hammer. By an elbow strike, which creates approximately the same force among different people, a trace-hole remains on the surface under study. In terms of its diameter, c. using a calibration table, evaluate the strength of the material .

A more accurate tool is the Kashkarov hammer, when using which the impact force of the ball on the material under study is taken into account by the size of the trace on a special rod located behind the ball.

But the most modern and accurate devices of mechanical action are spring ones: the device of the Academy Utilities RSFSR, Central Research Institute building structures. The principle of operation of these devices is based on taking into account a certain impact force caused by the descent of a cocked spring. A device of this type is a housing in which a spiral spring is placed, connected to a striker rod. After pressing the trigger, the spring is released and the firing pin strikes. In the TsNIISK device, the impact force can be set equal to 12.5 or 50 kg/cm2 for stone materials different strength.

To determine the bends and deformations of vertical surfaces, their shape and the nature of deviations from verticality and plane, a level with a special nozzle is used, which allows sighting, starting from 0.5 m instead of the minimum 3.5 m when there is no nozzle.

The relief of vertical surfaces is revealed by the method of sighting the instrument from one of its stands on the rail, applied horizontally to pre-designated points of the surface being examined. The results of measuring the deformations of horizontal or vertical surfaces are applied to diagrams, on which, for clarity, lines of equal deviations from horizontal or vertical are revealed, like horizontal lines planes. The cross section is given equal to 2-5 mm, depending on the degree of deviation or violation of the position or local defects of the element under examination and its overall dimensions.

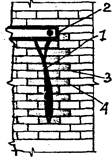

However, first of all, it is necessary to find out the nature of negative changes in the masonry and to establish whether the process of crack formation has stabilized, or whether their number and width of opening increase with time. For this, in the masonry itself, lighthouses. The lighthouse is a strip of gypsum, glass or metal covering both sides of the crack. Beacons made of gypsum and glass in the event of continued deformation, which caused the appearance of cracks, burst.

| Devices for diagnosing the strength of the material: a - Fizdel's hammer; b-the same Kashkarova; c - TsNIISK pistol: 1 - calibrated ball; 2 - angular scale; 3 -

calibration table; 4- replaceable rod for fixing the impact trace |

|

|

Measurement of deformations of a vertical surface using a level with an optical nozzle: a-plan; b- surface of the wall; c - incision; 1 - level; 2 - rail; 3 - places for applying the rail; 4 - lines of equal deviations from the plane |

|

Beacons for monitoring the state of cracks: /-crack; 2-plaster and alabaster mortar; 3- wall material; 4- gypsum lighthouse; 5 - glass lighthouse; 6 - metal plate; 7 - risks after 2-3 mm; 8 - nail |

By measuring the divergence of the lighthouse halves, the nature of the change in the crack or its stabilization is established. A metal beacon is attached to one side of the crack, and it can move along its other edge, along its other side, where the initial and subsequent positions of the end of the beacon are fixed. by the most simple beacon is an paper beacon, which is a strip of paper glued onto a crack, with further expansion of the crack, the paper beacon is torn.

Cracks in load-bearing stone structures correspond to the stages of crack formation (or stages of masonry work under compression). With efforts in masonry F

not exceeding effort F crc

, at which cracks appear in the masonry, the structure has a bearing capacity sufficient to absorb the existing load, cracks do not form. Under loads F  F crc

crack formation begins. Since the masonry does not resist stretching well, stretched surfaces(areas) cracks

F crc

crack formation begins. Since the masonry does not resist stretching well, stretched surfaces(areas) cracks

appear much earlier than the possible destruction of the structure.

The main reasons for the formation of cracks are:

1) poor quality of masonry (poor mortar joints, non-compliance with dressing, backfilling in violation of technology, etc.);

2) insufficient strength of the brick and mortar (fracturing and curvilinearity of the brick, non-compliance with the drying technology in its manufacture; high mobility of the mortar, etc.);

3) joint use in masonry of stone materials of dissimilar strength and deformability (for example, clay bricks together with silicate or cinder blocks);

4) use of stone materials for other purposes (for example, silicate brick in conditions of high humidity);

5) poor quality of work performed in winter (use of brick not cleared of frost; use of frozen mortar, absence of antifreeze additives);

6) non-fulfillment of thermal shrinkage seams or unacceptably large distance between them;

7) aggressive influences external environment(acidic, alkaline salt effects; alternate freezing and thawing, moisturizing and drying);

8) uneven settlement of the foundation in the building.

It is no coincidence that the settlements of the foundations are indicated last condition for the occurrence of cracks in the masonry. It should be borne in mind that during the period of mass construction, mortars without antifreeze additives were used in masonry, lean, non-plastic, i.e. very cheap. All this contributed to an abundant education shrinkage

cracks that need to be separated from the pure sedimentary

cracks that have a specific, easily identifiable character.

Consider the process of formation of cracks in masonry during compression

First stage- the appearance of the first hair cracks in individual stones. An effort F crc

, at which cracks appear at this stage, depends mainly on the type of mortar used in the masonry:

- in masonry on cement mortar F crc \u003d (0.8 - 0.6) F u; ;

- in masonry on a complex solution F crc \u003d (0.7 - 0.5) F u;

- in the masonry lime mortar F crc \u003d (0.6 - 0.4) F u,

where F u—

breaking force.

Second stage— germination and coalescence of individual cracks. This stage begins and proceeds more intensively along the southern facade of the building, which experiences the greatest temperature fluctuations in the atmospheric environment. In addition, crack propagation is observed at wrong organization external drains, violation of their system in places of periodic wetting of masonry.

Third stage- further formation of large fracture surfaces and exhaustion of masonry strength.

|

|

|

The photo shows a building with an attic, based on an internal transverse wall. On the free part of the roof, a slope was created for an organized system of external drainage, however, the corner of the building is significantly wetted. The arrow points to a developing crack that appeared after one year of operation of the reconstructed structure. |

Brickwork defects and their causes: a-wear from 20 to 40%; b-wear 41-60%; c - overloaded piers with wear up to 40%; g - the same, with more wear; e - exposure of brickwork when the plaster is worn |

Analyzing the pattern of cracks, it should be remembered that the appearance of individual cracks in the dressing stones indicates an overstress in the masonry. Crack development in the second stage indicates a significant overvoltage of the masonry and the need to unload or strengthen it.

When large destruction surfaces are formed, it is advisable to replace the masonry with a new one or reinforce it with a structure that fully perceives the operational load.

During the operation of the structure, cracks may open due to the unreasonably large length of the temperature block or due to the absence of a temperature-shrinkage joint at all. During the period of reconstruction with the construction of bay windows, hanging elevators, the installation of additional and attic floors cracks may appear in the masonry due to the insufficient area of \u200b\u200bsupporting the lintels on the wall and the low strength of the masonry, from overloading the pier and the low strength of the masonry. Other reasons for cracking are also possible. For example, randomly located cracks often occur in structures that are in close proximity to the place of driving piles, or in old buildings, the wear of brickwork of which reaches 40% or more.

Strength bricks and stones must be determined in accordance with the requirements of GOST 8462-85, solution- GOST 5802-86 or SN 290-74. Density and humidity masonry determined in accordance with GOST 6427-75, 12730.2-78 by establishing the difference in the weight of the samples before and after drying. The frost resistance of stone materials and mortars, as well as their water absorption, is established according to GOST 7025-78.

Samples for testing are taken from lightly loaded structural elements, provided that the materials used in these areas are identical. Samples of bricks or stones must be intact without cracks. From stones irregular shape cut cubes with a rib size from 40 to 200 mm or drill cylinders (cores) diameter from 40 to 150 mm. For testing solutions, cubes are made with an edge from 20 to 40 mm, composed of two mortar plates glued together gypsum mortar. The specimens are compressively tested using standard laboratory equipment. The areas of masonry from which samples were taken for testing must be completely restored to ensure the original structure.

Technology for the restoration and strengthening of brickwork

As noted above, the brick buildings of residential buildings of mass series had high reliability and a significant margin of safety. But a long service life, violations specifications contents could cause significant damage to the load-bearing brick walls. Depending on the visible damage and the state of the structures, the loads acting on them, and other factors that impede normal operation, during the reconstruction, measures are taken to restoration bearing capacity of masonry. In addition, with an increase in the number of storeys of a structure or another increase in the building volume of a structure, it becomes necessary to amplification brick structures.

Recoverybearing capacity of masonry reduced to sealing and localization of cracks. Naturally, this problem must be solved after identifying and eliminating causes of cracking:

1) eliminate or stabilize uneven foundation settlements by strengthening foundations or foundations;

2) change the conditions for transferring the load to the cracked wall in order to redistribute the load over a large area;

3) redistribute the load on other (or even additional) structures in case of insufficient strength of the masonry itself.

It should be noted that the sealing of cracks should also accompany measures to reinforcement of brick structures, which are necessary with increasing loads and the impossibility of their redistribution to other elements of the structure.

Technologically, sealing cracks in brick walls can be done by one of the following methods or a combination of them.

Crack injection - injection of solutions of liquid cement or polymer-cement mortar, bitumen, resin into the cracks of the damaged masonry. This method of restoring the bearing capacity of the masonry is used depending on the type of structure, the nature of its further use, the available injection options, and most importantly, with a local nature and a small opening of the crack. It can be done using various materials. Depending on their type, they are silicification, bitumization, resinization and cementation. Injection allows not only to monolithic masonry, but also to restore, and in some cases increase its bearing capacity, which occurs without increasing the transverse dimensions of the structure.

The most widely used cement and polymer-cement mortars. To ensure the effectiveness of the injection, Portland cement of a grade of at least 400 with a grinding fineness of at least 2400 is used. cm 2 /g, with a cement paste density of 22 - 25%, as well as Portland slag cement grade 400 with a low viscosity in diluted solutions. Sand for mortar is used fine with a fineness modulus of 1.0 - 1.5 or finely ground with a fineness of grinding equal to 2000-2200 cm 2 /g. To increase the plasticity of the composition, plasticizing additives are added to the solution in the form of sodium nitrite (5% by weight of cement), a PVA polyvinyl acetate emulsion with a polymer-cement ratio P / C = 0.6 or a naphthalene-formaldehyde additive in an amount of 0.1% by weight of cement .

Quite stringent requirements are imposed on injection solutions: low water separation, required viscosity, required compressive strength and adhesion, slight shrinkage, high frost resistance.

At small cracks in clutch (up to 1, 5 mm) use polymer solutions based on epoxy resin (epoxy ED-20

(or ED-16) - 100 wt.h.; modifier MGF-9 — 30 wt.h.; hardener PEPA - 15 wt.h.; finely ground sand 50 wt.h), as well as cement-sand mortars with the addition of finely ground sand (cement - 1 wt.h.; superplasticizer naphthalene formaldehyde - 0.1 parts by weight; sand - 0.25 parts by weight; water-cement ratio - 0.6).

At more significant crack opening apply cement-polymer mortars of the composition 1: 0.15: 0.3 (cement; PVA polymer; sand) or 1: 0.05: 0.3 (cement: plasticizer sodium nitrite: sand), W / C \u003d 0.6 , the modulus of sand size M to =1. The solution is injected under pressure up to 0.6 MPa. The crack filling density is determined 28 days after injection.

The solution is injected through injectors with a diameter of 20-25 mm. They are installed in specially drilled holes through 0.8-1.5 meters along the length of the crack. The diameter of the holes must ensure the installation of the injector tube on the cement mortar. Depth of holes - no more 100 mm, the injector tube is fixed in the hole with caulked tow.

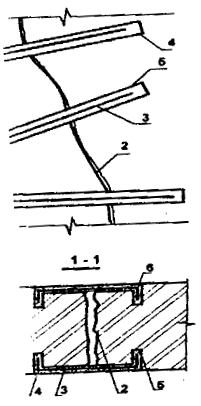

Injection of cracks up to 10 mm wide cement-sand mortar:

Injection of cracks up to 10 mm wide cement-sand mortar:

1 - masonry; 2- crack; 3- holes for injectors through 800-1500 mm; 4- steel tube of the injector; 5- tow, caulked with glue; 6- solution supply

Installation of reinforcing steel brackets

used in methods of restoring the bearing capacity of masonry when cracks open more than 10 mm. To do this, a recess is made in the masonry with a cutter according to the size of the bracket. The bracket is fixed with bolts along the edges, the crack itself is usually injected with a cement-sand mortar and caulked with a hard mortar.

Installation of reinforcing steel brackets: 1-reinforced wall; 2-crack in the wall, injected with cement-sand mortar after installation of brackets; 3-brackets made of reinforcing steel; 4-groove in masonry, selected by a cutter; 5-recesses at the ends of the groove, made with a drill; 6-filling with cement-sand mortar grooves and recesses

At significant damage masonry network of cracks staples perform bilateral, in this case, the masonry experiences double sided compression. Development of numerous through cracks can be stopped by using instead of staples strip steel linings , which are installed in increments of 1.5-2 wall thicknesses.

|

|

|

|

|

|

|

|

|

Double-sided brackets made of reinforcing steel on bolts: 1- masonry; 2- through crack; 3 - strip steel lining; 4- coupling bolts; 5 holes in the wall |

||

The destruction can be so significant that in some cases partial dismantling and re-laying of the destroyed brickwork is required. Typically this is done with the device inserts of brick locks equipped with an anchor .

|

wide, more 10 mm crack ( 1 ) intercepted by a one- or two-sided overlay ( 2) , taken no longer from strip steel, but from rolled metal, which is attached to the wall with anchor bolts. In this case, the overlay is called anchor. Along the entire length of the development of the crack, the damaged brick is removed to a thickness of two bricks and replaced with reinforced masonry on a cement-sand mortar, called brick castle (3-4

).

|

|

Partial or complete filling of openings with masonry: 1 - reinforced wall; 2-window openings; 3 - reinforced masonry of brick grade M75-100 on mortar M50-75; 4- seam, wedged with a metal plate and caulked with cement-sand mortar |

|

Scheme of unloading of brick walls: 1 - jumper / chka-, 2 - boards 50-60 mm; 3- racks with a diameter of more than 20 cm; 4 - wooden wedges; 5- temporary fastening of racks |

An increase in the bearing capacity and stability of the walls can be provided increase in cross-sectional area

, the device of various clips

or metal frame.

Increasing the cross-sectional area the wall is reached by increasing its width. In this case, new sections of masonry are laid out on both sides of the wall, which are securely tied up with the old one, and, if necessary, reinforced. Damaged load-bearing piers are unloaded, the cross-sectional area of the piers increases, respectively, the area of window openings decreases, so window blocks must be replaced.

When resting on a reinforced pier of a truss structure or deviating the wall from the vertical by more than 1/3 of the brick thickness, the pier is preliminarily unloaded by summing up temporary wooden or metal pillars on gypsum mortars.

main ways reinforcing masonry,

are well-proven methods of device clips, extensions

or shirts,

divided into reinforced concrete

and mortar

. When amplifying reinforced concrete clips, shirts and extensions class B10 concrete and class A1 reinforcement are used, the step of transverse reinforcement is taken no more than 15 cm. The thickness of the clip is determined by calculation and varies from 4

before 12 cm.

Mortar clips, shirts and extensions also called plastering, differ from reinforced concrete the fact that they use cement mortar grade 75-100, which protects reinforcement reinforcement.

Reinforced concrete frame device effective in case of surface destruction of the material of piers and pillars to an insignificant depth or in the event of deep cracks, when the piers can be widened. In the first case, the destroyed sections of the wall are cleared to a depth not less than the thickness of the reinforced concrete casing, and the section of the wall does not change as a result of its construction. In the second case, the section of the pier is increased due to the construction of a reinforced concrete cage.

The technological process of installing a reinforced concrete casing of piers consists of removing window fillings, clearing destroyed areas or cutting a pier to the required depth, removing window quarters, installing reinforcement, formwork, concreting, concrete maintenance, formwork removal and scaffold dismantling. The working reinforcement of a reinforced concrete cage can be pre-stressed by heating up to 100-150 ° C (for example, by heating with an electric current).

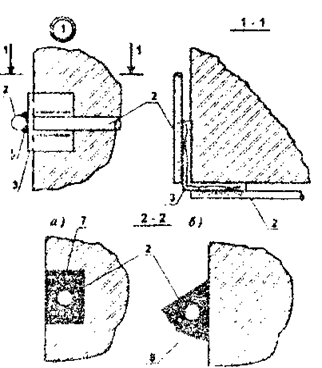

|

Arrangement of reinforced concrete clips: a - without increasing the section of the wall; b-with increase sections pier |

|

|

|

Arrangement of prestressed plaster casing: 1-reinforced wall; 2-metal plates with holes for cords; 3-strand-bonds; 4 holes in the wall for cords; 5-reinforcing rods welded to the plates and tightened in pairs; 6- cement-sand mortar plaster; 7-reinforcing mesh tied to rods |

Instead of reinforcing cages, when strengthening, it is possible to use meshes made of wire with a diameter 4-6 mm with cell 150x150 mm. In both cases, reinforcement and meshes and frames are attached to the reinforced surface with pins (anchors).

On the large areas additional clamps-connections are installed with a step of no more 1m with medium length 75 cm

The formwork of the reinforced concrete casing is built up from the bottom up during the concreting process. For the installation of reinforced concrete clips, the shotcrete method is used, in which formwork is not required. In this case, the pier is applied under pressure to the reinforced surface. concrete mix using a cement gun. The advantage of this method of arranging a reinforced concrete casing is the mechanization of the concreting process. Reinforced concrete clip increases the bearing capacity of the element enclosed in it by 2-Z times

|

|

|

Clamps-ties of reinforced concrete cage: 1-reinforced wall surface; 2 - fittings with a diameter of 10 mm; 3 - clamps-ties with a diameter of 10 mm; 4 - holes in the masonry; 5 - concrete clip; 6- reinforcing cages |

|

|

|

| The device of a plaster or reinforced concrete shirt: 1-reinforced wall; 2 armholes; 3-shirt plaster 30-40 mm or reinforced concrete 60-100 mm thick; 4-reinforcement with a diameter of 10 mm; 5-reinforcement with a diameter of 12 mm; 6-metal pins | Reinforced concrete core device: 1-reinforced wall; 2-openings; 3-rack (core) made of reinforced concrete;

4-niche cut in the wall; 5-reinforcing frame; 6-concrete |

Solution shirts and extensions

differ from clips in only one constructive feature- they are executed unilateral. The shirt can be made and not the entire width of the wall - in the form core.

Sometimes steel clips reinforcing brickwork on permanently operated buildings are left without protective coating mortar or concrete, arranging metal carcass

amplification.

|

|

| Reinforcement of piers with a metal frame: a- narrow pier; b- wide pier; 1- brick element; 2-steel corners; 3-bar; 4-cross link |

|

|

The device of overhead belts from the corners: 1-reinforced wall; 2 corners of overhead belts; 3-cross bars; 4-tie bolts; 5-plaster with cement-sand mortar on a metal mesh |

The device of the metal frame of the walls is less laborious and material-intensive than the device of a reinforced concrete cage, and is widely used.

Preparing for the device metal frames piers consists of unloading piers, removing the filling of window openings and felling quarters. With this method, at the corners of the piers, they are installed to their entire height and tightly adjusted to the piers of the angle steel rack, which, after 30-50 cm in height, are connected with strip steel welded end-to-end to the shelves of the corners. Then the wall is covered with wire metal mesh and plastered.

The metal frame can be applied to the wall or embedded flush into it. In the second case, before installing the frame, the corners of the walls are cut down and horizontal bars are punched in the places where the metal connecting strips are installed.

After installing the frame, the gap between metal elements and the wall is carefully minted with a solution. If the lintels resting on the pier have also been destroyed, it becomes more effective to reinforce the pier by bringing up racks from the corners. In this case, the racks are made slightly longer than the distance between the jumper and the floor. At the top, they are attached to the bare fittings of the lintels, and at the bottom, to the overhead belt from the channel, mounted on the body of the object being reconstructed. The racks are straightened in pairs with clamps, thus creating a prestress. Straightening, breaks, cuts in the shelves of the corners are welded.

Gain corners buildings, it is also advisable to produce using channel lining long 1.5-3 m. Overlays can be placed both from the outside and from inner surface walls. They are connected to the brickwork with the help of coupling bolts installed in pre-drilled holes. Coupling bolts are located along the height of the reinforced part of the masonry through 0.8-1.5 m.

|

|

Summing up racks from the corners: 1-reinforced wall; 2-openings; 3-racks from unequal corners, curved to the side; 4-line break; 5-mortgage detail; 6-bared fittings; 7-welding; 8-solution |

|

|

|

In the event of local deformations and to prevent further opening of cracks, it is carried out by strengthening junction zones longitudinal and transverse walls of the building unloading beams . Unloading beams are installed in previously punched grooves on one or both sides of the wall at the level of the top of the foundation or lintels of the first floor.

Bilateral beams through 2-2.5 m connected with bolts of diameter l6-20mm passed through previously drilled holes in the beams and the wall. One-sided beams are installed on anchor bolts, the smooth ends of which are fixed in the wall by installation on cement mortar in previously drilled sockets. Bolted beam connections are fastened with nuts. Step anchor bolts 2-2.5 m.

The gaps between the shelves of the beams and the brickwork are carefully minted with a 1: 3 cement mortar. For the manufacture of unloading beams, a channel or an I-beam No. 20-27 is used. In places where the walls break into cracks on each floor, screeds are installed from rolled scraps with a length of at least 2 m Before installing the screed bracket for it, a groove is cut down in the wall in such a way that the screed is installed flush with the surface of the brick wall. Holes for bolts are drilled in the wall and in the screed according to the marking 20- 22 mm, with which the bracket-screed is attached to the wall. The distance from the crack to the bolt installation site must be at least 70 cm. Before installation, the screed is wrapped around wire mesh or wire 1-2 mm. After installing the structure, the crack and the strebu are carefully sealed with a brand solution M100.

|

|

|

Installation of metal plates (framework) when reinforcing the building: 1-deformed building; 2-cracks in the walls of the building; 3-linings from channels or from metal plates; 5-tie bolts; 6-shtraba for installing plates, sealed with mortar; 7-holes in the walls for bolts, after installing the bolts it is caulked with mortar |

Typically, development cracks associated with uneven settlement of foundations, requires additional measures not only to increase the bearing capacity of the masonry, but the rigidity of the entire structure as a whole. Gross violation of masonry technology, unacceptable operating conditions of the structure, as in the case of uneven settlement of foundations, cause not only the development of cracks at window and door openings, but also violations of the verticality of the enclosing structures.

In places detachment of external walls from internal to restore the rigidity of the building establish connections from metal frames or reinforced concrete dowels. In this case, the building is said to be reinforced.

However, most often, after eliminating the causes of uneven settlement of the foundation, the building needs to be contraction of the body generally. Perhaps the only way to do this is to creation of tension belts .

|

|

|

|

Arrangement of external stressed belts: 1-deformed building; 2-steel strands; 3-rolled profile from corner No. 150; 4 turnbuckles; 5-weld; 6- cracks in the walls of the building; 7-shtraba in the wall for filled with cement-sand mortar

It should be emphasized here that the most common error in strengthening the hull brick buildings with hard constructive scheme is the creation vertical stiffening disks(laying or reducing the area of window openings, installing vertical metal frames, etc.), while here the most important horizontal hard disk. A tense belt, also called a "bandage", is taken from reinforcing bars with a diameter 20-40 mm connected with turnbuckles.

In rare cases, rolled steel is used instead of reinforcement. The result is a reinforcing element that perceives both tensile and compressive forces, called bracing. Ties-spacers are installed at the level of the coating and at the level of intermediate floors, they can be located both from the outside and from inside structures.

|

|

|

|

| Arrangement of internal stressed belts: 1-deformation building; 2-steel bands with nuts; 3-metal plates; 4 turnbuckles; 5-holes in the walls, which are sealed with mortar after packing the strands; 6-cracks in the walls of the building | |

Reinforcement of floors residential buildings of series 1-447 is determined by the presence of short cracks and fragmentation of brick stone at the points of support of floor slabs. The main reason for the destruction is usually insufficient support area of the floor slab or the absence of a distribution cushion.

Most effective methodology amplification is a mounting technology steel rods and braces under the floor slab, since, as already noted, the creation of a horizontal stiffening disk in buildings of this type is of paramount importance. However, this is a very expensive and busy way, it is possible only with a complete reconstruction with the resettlement of residents. Therefore, they try to local reinforcement of damaged structures.

Local strengthening, depending on the type of floor slabs, with partial or phased reconstruction is carried out by:

—increasing the area of bearing of the beam with the help of metal or reinforced concrete racks, the force from which is transmitted outside the destruction zone;

-increasing the area of support of the slab by means of a belt fixed in the zone of destruction of the masonry;

-devices under the end of the floor slabs of the reinforced concrete cushion.

Calculation of brick elements reinforced with reinforcement and clips

Longitudinal reinforcement , intended for the perception of tensile forces in eccentrically compressed elements (with large eccentricities), in bending and tension elements, in reinforcing brickwork during reconstruction, is quite rare, therefore it is not considered in this section. However, with the growth seismic danger of some regions of central Russia due to underground workings and other anthropogenic factors, as well as when laying railways and highways near residential areas, longitudinal reinforcement is used when facing thin (up to 51 cm) brick walls of reconstructed buildings.

Mesh reinforcement masonry sections significantly increases the bearing capacity of reinforced elements of stone structures (pillars, piers and individual sections of walls). The effectiveness of mesh reinforcement during reinforcement is determined by the fact that reinforcing meshes placed in horizontal seams of masonry sections prevent its transverse expansion during longitudinal deformations caused by acting loads, and due to this increase the bearing capacity of the masonry body as a whole.

Mesh reinforcement is used to reinforce masonry made of bricks of all types, as well as ceramic stones with slit-like vertical voids with a row height of not more than 150 mm. Reinforcement with mesh reinforcement of masonry made of concrete and natural stones with a row height of more than 150 mm little effective.

For masonry with mesh reinforcement, mortars of grade 50 and higher are used. Mesh reinforcement is used only for slendernesses or , as well as for eccentricities that are within the core of the section (for rectangular sections e 0<0,33 y). При больших значениях гибкостей и эксцентрицитетов сетчатое армирование не повышает прочности кладки.

For example, it is required to determine the cross section of the longitudinal reinforcement for a brick pillar 51 x 64 cm, height 4.5 m. The pillar is lined with ordinary clay bricks of plastic pressing brand 100

on brand solution 50

. In the middle section of the column, the reduced design longitudinal force acts N p=25 t, applied with eccentricity e o =

25 cm in the direction of the side of the section, which has a size of 64 cm.

We reinforce the column with longitudinal reinforcement located in the stretched zone outside the masonry. We constructively reinforce the compressed zone of the column cross-section, since with the external location of the reinforcement, frequent installation of clamps will be required to prevent buckling of the compressed reinforcement, which will require additional steel consumption. The installation of structural reinforcement in the compressed zone is mandatory, as it is necessary for fastening the clamps.

Cross-sectional area of the column F \u003d 51 x 64 \u003d 3260 cm 2. R \u003d l5 kgf / cm 2(at F> 0.3 m 2). Design resistance of longitudinal reinforcement made of class steel A-1R a=l900 kgf / cm 2.

Tensile reinforcement is taken from four rods with a diameter of 10 mm F a \u003d 3.14 cm 2.

Determine the height of the compressed zone of the section X at h 0 =65 cm, e=58 media b=51 cm:

1.25-15-51 x (58-65+) -1900 -3.14-58 = 0,

and from the received quadratic equation determine x= 35 cm<

0.55h o =36 cm.

Since the condition is satisfied, the bearing capacity of the section is determined by at = 1000:

pr ===7

hence = 0.94.

Bearing capacity of section

0.94 (1.25 x 15 x 51 x 35-1900 x 3.14) = 25.6 t > N p = 25 t.

Thus, with the accepted cross section of the reinforcement, the bearing capacity of the column is sufficient.

Complex structures are made of masonry reinforced with reinforced concrete, working together with the masonry. Reinforced concrete is recommended to be placed with outside masonry , which allows you to check the quality of the laid concrete, the grade of which should be taken equal to 100-150.

Complex structures are used in the same cases as masonry with longitudinal reinforcement. In addition, it is advisable to use them, as well as mesh reinforcement, to reinforce heavily loaded elements in axial or eccentric compression with small eccentricities. The use of complex structures in this case makes it possible to drastically reduce the cross-sectional dimensions of walls and pillars.

Elements reinforced with clips are used to reinforce pillars and piers having a square or rectangular cross section with an aspect ratio of no more than 2.5. The need for such reinforcement arises, for example, when building on existing buildings. Sometimes it is necessary to reinforce masonry that has cracks or other defects (insufficient strength of the materials used, poor quality masonry, physical wear, etc.)

Clips, as well as mesh reinforcement, reduce transverse masonry deformations and thereby increase its load-bearing capacity. In addition, the clip itself also takes part of the load.

In the previous sections, three types of clips were considered: steel, reinforced concrete and reinforced plaster .

The calculation of elements made of brickwork reinforced with clips, with central and eccentric compression at small eccentricities (not extending beyond the core of the section) is carried out according to the formulas:

with steel frame

N n [(m to R + ) F+R a F a];

with reinforced concrete frame

N n [(m to R + ) F+m b R pr F b + R a F a];

with reinforced plaster clip

N (m R + ) F.

The values of the coefficients and are accepted:

at central compression=1 and =1;

in eccentric compression (by analogy with eccentrically compressed elements with mesh reinforcement)

1 - , where

N p - reduced longitudinal force; F- masonry cross-sectional area;

F a- cross-sectional area of the longitudinal corners of the steel cage, installed on the solution, or the longitudinal reinforcement of the reinforced concrete cage;

f b - cross-sectional area of the concrete of the casing, enclosed between the clamps and the masonry (excluding the protective layer);

Ra- design resistance of the transverse or longitudinal reinforcement of the clip;

- buckling coefficient, when determining the value a accepted as for unreinforced masonry;

t to - coefficient of masonry working conditions; for masonry without damage t to=1; for masonry with cracks t to =0,7;

t b - coefficient of concrete working conditions; when transferring the load to the holder from two sides (from below and from above) t b

=1; when transferring the load to the cage from one side (from below or from above) t b=0.7; without direct load transfer to the cage t b =0,35.

- percentage of reinforcement, determined by the formula

x 100,

where f x- cross-section of the clamp or cross bar;

h and b- dimensions of the sides of the reinforced element;

s- the distance between the axes of the transverse bars with steel clips ( hsb, but not more than 50 cm.) or between clamps with reinforced concrete and reinforced plaster clips (s15 cm).

For example, in the middle section of the pier with a size of 51x90 cm, located on the first floor of the building, after the completion of the construction of the superstructure, the calculated longitudinal force will act N n =60 t applied with eccentricity e about = 5 cm, directed towards the inner edge of the wall. The pier is lined with silicate brick grade 125 on mortar grade 25. The height of the wall (from the floor level to the bottom of the precast concrete floor) is 5 m. It is required to check the bearing capacity of the wall.

Section of the pier F \u003d 51 x 90 \u003d 4590 cm 2\u003e 0.3 m 2.

Estimated masonry resistance R \u003d l4 kgf / cm 2. Distance from the center of gravity of the section to its edge towards the eccentricity

y = = 25.5 cm; = =0.2<0,33,

the eccentricity is within the core of the section. We rely on the wall for eccentric compression with a small eccentricity. The elastic characteristic of masonry made of silicate brick on a mortar grade 25 - = 750.

The reduced flexibility of the wall np == 11.3.

Buckling ratio = 0.85.

Coefficient taking into account the effect of eccentricity, = = 0.83.

Determine the bearing capacity of the wall:

0.85 x 14 x 4590 x 0.83 = 45200kgf

Since the bearing capacity of the wall turned out to be insufficient, we reinforce it with a clip of steel isosceles corners measuring 60x60 mm, d=6 mm. The corners are installed on the solution in the corners of the wall and are interconnected by strip steel strips with a section of 5x35 mm, welded to the corners at a distance s=50 cm along the height of the wall.

Next, we determine the bearing capacity reinforced pier. Coefficient of masonry working conditions t k \u003d 1. Design resistance of steel strips Ra =1500 kgf / cm 2. Plank area f x\u003d 0.5x3.5 \u003d 1.75 cm 2. Estimated resistance of the clip corners (the load on the corners is not transferred) Ra =430 kgf / cm 2. Sectional area of corners Fa\u003d 6.91x4 \u003d 27.6 cm 2. Next, we determine the coefficients and , =0,83, =1-=0,61 and the corresponding percentage of reinforcement: \u003d x 100 \u003d 0.21%

Hence, the bearing capacity of the reinforced pier will be:

0.83.0.85[(14 +0.61xx)4590+430 x27.6]=63800kgf > N p \u003d 60000 kgf

The bearing capacity of the reinforced pier is sufficient.

Work to ensure the stability and rigidity of the walls of the building begins after stabilization and elimination of the causes of deformations that caused violations.

To restore the performance of the walls, prestressed steel strands are installed, and reinforced concrete or reinforced brick belts are also arranged.

The device of prestressed steel strands(Fig. 5) is one of the effective methods for increasing the spatial rigidity of buildings.

Bands made of round reinforcing steel with a diameter of 28 ... 38 mm are installed in grooves punched along the perimeter of the building at the level of interfloor ceilings. The supports of the strands at the corners of buildings are corners that protect the masonry of the walls from local collapse and transfer the compression forces to a large area. Tension is performed by turnbuckles; it can be effectively combined with thermal tension.

Fig.5 Installation of steel ties:

a - building's facade; b- plan; 1 - steel bands; 2 - turnbuckles

The results of the introduction of prestressed steel rods testify to the efficiency of this method, achieved as a result of replacing expensive and labor-intensive work to strengthen foundations and foundations with relatively easy work, as well as its reliability. The use of steel strands is advisable for capital buildings, the wear of the walls of which does not exceed 60%.

Reinforced concrete and reinforced brick belts (Fig. 6) are used, as a rule, for the superstructure of buildings or an increase in operational loads that can cause uneven settlement of buildings. Such belts serve to uniformly transfer the load to the underlying walls of the building, absorb tensile forces that occur during uneven settlement, and maintain the overall rigidity of the building while increasing the strength of the walls.

Fig.6 Wall reinforcement:

a - reinforced concrete belt; b - reinforced seam; 1 - corner; 2 - reinforced brick belt

Belts are located at the level of interfloor ceilings in the form of continuous tapes lying on all main walls, including transverse ones. Belts must have a reliable connection with the walls. The cross section of the reinforcement in them is taken according to the project; it should be within 6 ... 10 cm, depending on the section of the belt.

Reinforced concrete belts are not placed over the entire thickness of the outer walls in order to preserve their thermal properties. On the inner walls, the belts can be along the entire thickness of the walls. When crossing the belts with channels located in the walls, holes are arranged in the belts to pass communications.

With minor deformations of the walls, reinforced seams or reinforced brick belts are arranged. Reinforced seams are made with a thickness of 50 ... 60 mm along the perimeter of all main walls. The amount of reinforcement is the same as in the case of reinforced concrete belts. The effectiveness of the reinforced joint is greatly increased by the transition to the reinforced brick belt, which consists of two reinforced joints located one above the other through 4 ... 6 rows of brickwork and interconnected by vertical rods.