How to make a deformation seam. Construction of expansion joints in foundations. The use of various types of seams in construction

New sealing technology - "warm seam"

The problem of freezing in winter time years of exterior panels in apartment buildings can be solved by technology

restorative repair of seams that form at the joints of wall panels. If the seams are repaired, the quality of thermal insulation and sealing of the space between the panel will increase significantly, and the humidity in the room will stop rising and the temperature will drop.

This sealing of the seams is called "warm seam" and is very good recommendations after a fairly wide application throughout Russia, regardless of climatic zones and temperature differences.

The seam treatment method proposed by our company provides for the use in stages of materials such as Macroflex sealant, Oksiplast sunscreen mastic, Vilaterm-SP polyurethane foam insulation. And heat-insulating and sealing works on this technology are carried out as follows.

First, the repaired joints of the wall panels are properly processed. Then, if necessary, the damaged sections of the facade of the building are restored at the joints of the outer panels. Then, the inter-panel seams of the building are re-insulated, carefully and intensively. And only then is the thermal insulation and sealing of the joints of the panels on the facade outer part of the building carried out directly, which should restore the performance of the panels and the building itself.

When we talk about preliminary work - processing of seams, we mean cleaning the seams from dirt and remaining paint, from any traces of previously used sealant, removing those sections of the panel that have peeled off, from the remnants of the solution. Also to preparatory work includes crack bridging. All cleaning operations, according to technology, are carried out only manually, no electrical engineering.

True, you can use some mechanical tools, such as a scalpel or a hammer.

High-quality sealing of seams is possible only on absolutely dry edges of the joints. During repair and restoration work, sealing panel seams produced (according to the “warm seam” technology) using sealing gaskets of the brand “Vilaterm-SP”

Only after careful preparatory work, in a completely cleared and completely dry joint, a gasket is placed (for sealing), which first passed preliminary procedure“compression” by about fifty percent. The gasket "Vilaterm-SP" is laid along the entire length of the joint, without gaps.

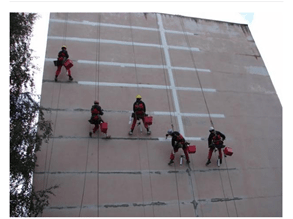

The final sealing of the seams - to fill the joint cavity with a special sealant - is a responsible procedure that can only be performed by industrial climbers. Because this action takes place on the outside of the wall. Specialists for this work use an aerosol can with a special tip. Depending on how wide the joint is, the procedure for filling the joint cavity is carried out once or repeated as many times as necessary.

Please note that sealing and thermal insulation works can only be carried out at temperatures from +35 to -15 degrees Celsius.

Question from a client

Hello.

Can you tell me, please, what are these cracks (or just open joints) along the gutters?

Cracks from 1 to 5 floors.

The house is brick.

How dangerous are they and how much will your termination work cost?

Good afternoon, Irina!

The cost of work is 480 rubles per meter (approximately what you sent in the photographs you have 3 seams of 17 meters each, approximately 25 tr.) But most likely each such seam has a full seam on the other side of the house (if they are already sealed during operation)

So I understand you sent a photo of the courtyard part of the house and the facade was repaired at one time ....

Sincerely, Vadim Snyatkov

thank you very much for the information.

I'll pass it on to my neighbors.

Materials and technology for waterproofing expansion joints

Home / Seam Sealing Articles / Sealing expansion joints in walls

/ Who should close the interpanel seams in an apartment building?

/ Insulation and sealing of interpanel seams

/ Repair of interpanel seams

/ Insulation technology warm seam prices

/ Materials for sealing interpanel seams and joints

/ What to do if you have poor quality seam sealing work

/ How to remove the fungus on the wall in the apartment

/ Sealing expansion joints in walls

/ Primary sealing of interpanel joints and secondary sealing

/ What are the designs of joints of wall panels

/ Sealing of interpanel seams by climbers Price

/ Sealant for interpanel seams and joints, which is better?

/ Sealing window seams from the outside: materials and sealant for window slopes

/ The wall in the apartment freezes through what to do where to go?

/ Monolithic belts repair and finishing

Types of expansion joints and their waterproofing

Deformation is a change in the shape or size of a material body (or part of it) under the influence of any physical factors (external forces, heating and cooling, changes in humidity from other influences). Some types of deformations are named in accordance with the names of the factors affecting the body: temperature, shrinkage (shrinkage is a reduction in the size of a material body when its material loses moisture); sedimentary (settlement - subsidence of the foundation during compaction of the soil under it), etc. If a material body is understood as separate structures or even constructive system in general, such deformations under certain conditions can cause violations of their bearing capacity or loss of performance.

Long buildings are subject to deformations under the influence of many reasons, for example: with a large difference in the load on the base under the central part of the building and its lateral parts, with heterogeneous soil at the base and uneven settlement of the building, with significant temperature fluctuations in the outside air and other reasons.

In these cases, cracks may appear in the walls and other elements of buildings, which reduce the strength and stability of the building. To prevent the appearance of cracks in buildings, expansion joints are arranged that cut the buildings into separate compartments.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Temperature expansion joint

Structurally, the expansion joint is a cut that divides the entire building into sections. The size of the sections and the direction of division - vertical or horizontal - is determined by the design decision and the power calculation of static and dynamic loads.

To seal the cuts and reduce the level of heat loss through expansion joints, they are filled with an elastic heat insulator, most often these are special rubberized materials. Thanks to this division, the structural elasticity of the entire building increases and the thermal expansion of its individual elements does not have a devastating effect on other materials.

As a rule, the temperature expansion joint runs from the roof to the very foundation of the house, dividing it into sections. It does not make sense to divide the foundation itself, since it is below the freezing depth of the soil and does not experience such a negative impact as the rest of the building. Per step warp expansion joints will affect the type of applied building materials and geographic location object that determines the average winter temperature.

Sedimentary expansion joint

The second important area of application of expansion joints is the compensation of uneven pressure on the ground in the construction of buildings with a variable number of storeys. In this case, the higher part of the building (and therefore heavier) will press on the ground with more force than the lower part. As a result, cracks can form in the walls and foundation of the building. A similar problem can be soil settlement within the area under the foundation of the building.

To prevent cracking of the walls in these cases, sedimentary expansion joints are used, which, unlike the previous type, divide not only the building itself, but also its foundation. Often in the same building there is a need to use different types of seams. Combined expansion joints are called temperature-sedimentary.

Anti-seismic expansion joints

As their name implies, such seams are used in buildings located in seismically hazardous zones of the Earth. The essence of these seams is to divide the entire building into "cubes" - compartments that are themselves stable containers. Such a "cube" should be limited by expansion joints on all sides, along all faces. Only in this case the anti-seismic seam will work.

Along the anti-seismic seams, double walls or double rows of supporting columns are arranged, which are the basis of the supporting structure of each individual compartment.

Shrink expansion joint

Shrinkage expansion joints are used in cast-in-situ concrete frames, since concrete, when hardened, tends to decrease somewhat in volume due to water evaporation. The shrinkage seam prevents the occurrence of cracks that violate bearing capacity monolithic frame.

The meaning of such a seam is that it expands more and more, parallel to the hardening of a monolithic frame. After the hardening is over, the resulting deformation seam is completely minted. To give hermetic resistance to shrinkage and any other expansion joints, special sealants and waterstops are used.

The picture shows two sections of a residential building in Maryino. They converge at an angle and are connected by balconies. Between balconies on both sides - Expansion joints between buildings. First, we sealed the joints with vilaterm with a diameter of 40 and 60 mm, then closed them with a strip of painted galvanized sheet. The sheets were attached with dowels and self-tapping screws to the wall; they were not attached to the building with dowels, the solution was to glue it with sealing mastic.

Expansion joints between buildings - filling vilaterm

If we have two sections of houses, docked with blank end walls. There is only one constructive solution, it is necessary to perform a sealing unit for two walls in a manner that is used at the joints of panels of panel houses. I will only clarify that sealing must be done around the entire perimeter of the joint, that is, close the parapet on the roof too. The sealing gasket must be inserted with 25-30% compression, i.e. select the cross section according to the size of the gap between the walls (if there is a gasket).

The sealing of joints of expansion joints of building structures and its individual elements is carried out by viloterm / isonel with a compression of at least 60%. The diameter is selected depending on the width of the seam. A mastic with a high adhesion index and a high elongation coefficient is applied over the vilaterm. Sometimes Macroflex foam is used for good fixation of the vilotherm and additional thermal insulation. If it is provided by the project for the building.

7.220. Expansion joints in the walls and ceilings of stone buildings are arranged in order to eliminate or reduce the negative impact of temperature and shrinkage deformations, foundation settlements, seismic effects, etc.

Outcome: in normative documents the mandatory need to seal these seams is not stipulated. All this is determined from the conditions of construction and subsequent operation of the building, that is, it should be reflected primarily in project documentation and then already completed by the builders.

Methods for sealing interpanel seams in panel buildings

Before starting work on sealing interpanel seams (joints), it is necessary:

determine the cause of freezing, leakage of panel seams.

We will carry out comprehensive work on sealing and repairing interpanel seams of the entire building or problem areas of the facade of the building.

Before starting work, a specialist will visit the site to inspect and select materials.

We will select materials for sealing joints based on the type of joints, weather conditions and wishes of the customer.

The work will be carried out using technologies industrial mountaineering or traditional methods of work (scaffolding, cradles).

Our climbers have been trained in specialized training centers, they know construction specialties, and most importantly, they have a large practical experience works on sealing interpanel seams of buildings.

Stages of work on sealing interpanel seams of panel buildings

Before starting work on sealing interpanel seams (joints), it is necessary to determine the cause of freezing, leakage of panel seams.

Inspection of interpanel joints

The scope of work on sealing interpanel seams depends on the type of seam defects, the place of their manifestation and the design of the sealed joints.

If defects in inter-panel seams are detected more than 25% of the estimated scope of work on sealing seams on the facade, it is necessary to seal inter-panel seams and joints throughout the entire scope of work, also to seal the joints between the balcony panels and the exterior inter-block panels of the house, as well as adjoining windows to the panels.

In the presence of spot leaks in the interpanel seams, the interpanel seam itself, as well as the horizontal and vertical interpanel external seams adjacent to it on the facade of the building and the adjunction of window blocks to the panel of this seam, are subject to repair.

If there are leaks at the junction of window and balcony blocks to the panels of the house, only these seams are subject to sealing.

If the seam freezes or "blows through", then only defective interpanel seams are subject to repair and sealing.

Methods for carrying out high-altitude work on sealing interpanel seams of buildings

After examining the interpanel seams of the building, one of the following options for sealing and repairing interpanel seams is selected:

Sealing of interpanel seams with 100% opening of joints to be repaired with their subsequent cleaning and sealing;

Repair and restoration sealing of the external seams of the building with partial opening of defective seams;

Surface sealing of house panel joints.

Technology for sealing interpanel seams

Preparation of interpanel repair joints

Preparation includes cleaning the surface of the seam from old sealant, paint, dirt. The edges are cleaned with a brush and degreased with a solvent.

Laying insulation

After preparation, heat-shielding polyurethane sealant "Macroflex" is poured into the empty joint between the panels. When hardened, this sealant expands and fills all the voids and cracks.

After pouring "Macroflex", a hollow insulation "Vilaterm" with a compression of 15-30% is applied to the polyurethane sealant that has not yet hardened.

Vilaterm is laid a little deeper than the plane of the wall, the remaining groove is filled with sealant.

Sealant laying

The sealant is applied with a spatula and special spatulas.

Materials for waterproofing interpanel joints

Frequently asked questions about seam sealing:

/

The foundation is the supporting structure of the entire building, therefore, the life of this building depends on its quality performance. During the construction of any foundation structure important role play deformation seams.

An expansion joint is a specially designed area that performs a protective function and allows the foundation to withstand temperature and soil fluctuations. The expansion joint in foundations has received the greatest distribution in areas where seismic activity is increased. Most often protected belt type grounds.

All expansion joints used in modern construction industry are divided into the following types:

- Sedimentary;

- Temperature;

- shrinkable;

- Seismic.

The choice of the desired type of seam depends on the type of soil and the temperature parameters of the region.

The calculation of the exact number of joints required should be carried out by an experienced surveyor. In order to correctly arrange a seam that protects the foundation from deformation, it is necessary to adhere to certain rules:

- The height of the expansion joint for the foundation must be equal to the height of the base itself;

- The step between the seams is determined on the basis of calculations. The average figures are as follows: if the house has wooden walls, the step will be 0.6 m; brick walls - 0.15 m;

- The structure of the future building also plays an important role. If the house is with an extension, then expansion joints are also required along the corner borders;

- The width of each seam is on average 10 to 12 cm;

- The choice of heat and water insulator for each type of base will be different: slab foundation it is better to protect with tarred tow, and tape - separately with a heat-insulating and waterproofing layer;

- During the construction of the blind area, one or more wooden slats are used, which are poured with bitumen;

- A seam between the blind area and the foundation structure is not required if the base is already isolated from moisture and cold.

The tips listed above are universal and apply to all types of expansion joints. Following these tips will allow you to build a strong and reliable foundation that will last for decades.

The device of the seam that protects the foundation from deformation

The difference between expansion joints from each other predetermines the scope of their application. For example, the device of a seismic seam on foundations is justified in areas of increased seismic activity. It takes on the load during ground vibrations and protects the building from deformation. If it is required to make a seam between the main building and the extension, the foundations of these structures must be separated by a layer of penplex, styroform or armoflex 2 cm thick. This measure will smooth out possible fluctuations.

The zones for the installation of expansion joints on foundations are regions where the air temperature during the year has a large range. To smooth out soil movements due to temperature changes, the foundation area under the house is divided by wooden slats into separate sectors (maps). Such seams are more popular when protecting unheated premises.

Shrinkage expansion joints are mounted between the layer of foundation blocks and the concrete poured from above. The reason for such operations is to take into account the ability of concrete to decrease in size when water evaporates.

The construction of a sedimentary protective seam is shown during the construction of the foundation under a multi-storey building. This allows you to evenly distribute the total load and prevent all kinds of damage.

Installation of seams against deformation of buildings is carried out with the involvement of various profiles. In other words, modern builders select the best version of the profile and make it a deformation seam for the foundation.

Important: all expansion joints arranged at the base of the building must be clearly stated in the project documentation.

The purpose of installing foundation joints is to protect the structure from deformation and ensure its stability.

How to fill expansion joints

If the seam at the base of the structure is not properly arranged, it may collapse. It is very important to use only high-quality sealants, the elasticity index of which is suitable for sealing such joints. The material for the manufacture of such sealants are polymers (butyl rubber, silicone, polyurethane, etc.).

Most popular when working on expansion joints is a polyurethane sealant that provides greater endurance and long service life of insulated structures. The cost of this material is different from other offers, but it's worth it.

Preparation for sealing is aimed at cleaning the seam from dust and dirt. So the treated seam will receive a high-quality and durable coating. Sealants based on polyurethanes, in addition to high elasticity, have high level adhesion to the surface, heat-resistant and withstand temperature fluctuations from -100°C to +100°C.

How to isolate the seams

The entire structure of the house under construction in the drawings is divided into separate sections- Knots for expansion joints. A mandatory point for the installation of such seams is their waterproofing, especially if there is a basement or basement floor.

When choosing a waterproofing material, the determining factors are the size of the seam, the likelihood of deformation, pressure and maximum load, the nature of the impact on the seam. key point is the water pressure value.

When designing a waterproofing expansion joint, the most efficient technology- an artificially formed loop, which subsequently collects moisture. In addition, the device of moisture-absorbing pads in the very thickness of concrete is shown. After protecting the seams from moisture, it is necessary to carefully check all joints for leaks.

Expansion foundation joints arranged in accordance with all the rules ensure the reliability of the foundation of the building for many years. This is especially true on shaky, unstable soils. At the stage of designing houses and industrial facilities in seismically active regions, the installation of expansion joints is one of the mandatory items of design estimates. The laying, sealing and waterproofing of these joints also affect the overall strength of the foundation.

Construction of expansion joints in foundations updated: February 26, 2018 by: zoomfund

Read on topicAny structures and structures are subject to deformation for various reasons: building settlement after construction during operation, temperature and seismic effects, soil heterogeneity at the base of structures. Undoubtedly, in the design and construction it is necessary to take into account all these factors and make the facility as safe as possible for people, as well as minimize the possibility of damage and the risk of frequent repairs. Because in modern world Increasingly, large and massive structures are being built, both residential and commercial, industrial, it is impossible to do without the use of expansion joints in all structural elements of buildings.

Definition, purpose of expansion joints

In order to reduce stress in structures due to deformation and shrinkage of elements of buildings, bridges, roads and other structures, expansion joints are arranged in them. These are elements that divide the entire structure into separate blocks, which allows them to move freely in certain directions. This phenomenon significantly reduces the risk of destruction of structures in places of possible deformation. Sections separated by such seams settle evenly within their volume, without interfering with the integrity of neighboring blocks.

Types of expansion joints

There are many classifications of expansion joints.

Types of expansion joints according to the nature of the load, due to which deformation occurs:

- Sedimentary. These deformations occur due to uneven compaction of soils under different parts of the building. This can happen for several reasons. First, changes are affected by uneven weight distribution. In modern architecture, houses are often built with different heights, with many design features in parts of the building. Secondly, the reason may be the heterogeneity of soils under individual parts of a structure or house. Homogeneous soil under the entire base is considered an ideal case, which is extremely rare. With a significant difference in the values of the settlement of individual elements, vertical deformations can occur in the form of fractures, shears, cracks, and displacements. Settlement-type expansion joints are calculated for each case separately and arranged vertically along the entire height of the building from the foundation. They are designed to compensate for the difference between the settlement of individual structural blocks.

- Shrink. Such deformations are caused by a decrease in the volume of structures and elements. All concrete monolithic parts and masonry: when solidifying and hardening, the mixture loses moisture. This aspect is also calculated, and the structure is divided into certain parts to avoid cracks, breaks, etc.

- Temperature. It is especially important to take into account this type of deformation in areas with climate change: summer-winter. At different times of the year, the structures of the outer parts are exposed to temperatures, which affects their volume. Especially in winter, when the wall with inside indoors and outdoors has a significant temperature difference. Despite the fact that its inner part has a constant temperature, and the outer part undergoes great changes, inside the structure, internal stress that can reach the limit and lead to irreversible consequences. To solve this problem, temperature seams are arranged. Often they coincide with shrinkage. Unlike sedimentary joints, expansion joints are necessary only in the ground part of buildings, since the foundation does not experience large temperature fluctuations if it is calculated and arranged correctly.

- Seismic loads occur in areas with frequent earthquakes and ground vibrations. In these cases, the buildings are divided in a special way into separate independent blocks, separated by special seismic expansion joints, which have a special structure, which makes it possible to maintain the integrity of the structures during seismic activity.

In addition, expansion joints in buildings are classified according to the type of structure in which they are arranged. Allocate seams located:

- in the walls;

- in foundations;

- in concrete floors;

- in monolithic slabs.

The expansion joint in each element has a separate structure. Thus, the features of changes in forms and loads for each section and direction are taken into account. This classification can additionally include an expansion joint between buildings. For example, in urban space, you can often find interconnected residential buildings and shops. They, as a rule, have different architectural features, volumes and sizes, materials of construction, but they are united by one common wall. So that these objects do not affect each other's changes, compensating seams are also arranged between them.

Design: the main nuances

When designing buildings, all possible loads that will affect structural elements are taken into account, and, depending on this, expansion joints are distributed in such a way that they compensate for all destructive effects directed to each element.

The device of expansion joints is diverse. They are produced at the construction site from special materials or from the increasingly popular finished metal profiles. The design of a metal expansion joint includes special rolled products and (if necessary) inserts made of various materials, selected depending on the place of application. For each element of the building, the guides have a different structure and are prepared from dissimilar materials, since they perform different functions.

At the design stage, not only the location of compensating cuts, their frequency, size and composition are calculated. Often, for individual places, a different expansion joint is determined. The node, which reflects the principle of adjoining structures, must be drawn and painted in detail so that there are no difficulties with its assembly at the construction site. In each case, the composition and type of the seam can be individual, since different parts of the structures experience certain loads, which are not always the same. Such situations can arise at the interfaces of blocks of different heights, destinations, weights, etc.

Expansion joint in different building elements

For all designs, the device of compensating gaps is individual, they have their own technical solution, composition, dimensions and features. Each material and design has its own expansion joint. SNiP 2.03.04-84 gives an example of calculations for the most common reinforced concrete structures in various conditions, SNiP 2.01.09-91 talks about calculations in subsidence soils and undermined areas.

Seams in foundations: purpose

The foundation is one of the most complex and critical parts of any structure in the construction. The safe functioning and reliability of the structure depend on its integrity. Therefore, in its design, everything must be thought out to the smallest detail - from the correct design solution to correctly arranged expansion joints. The foundation experiences several types of destructive loads at once: from shrinkage and seasonal movement of the soil; uneven subsidence different parts building. The outer perimeter may be subject to temperature changes (in rare cases, it is more often referred to the upper part of the foundation wall, which passes into the basement). The expansion joint in the foundations must compensate for all incoming influences and give it elasticity and mobility. In addition, it must have high-quality external waterproofing, which will prevent the penetration of moisture into the body of the seam to avoid destruction of its very foundation.

Device Features

The expansion joint in the foundations is arranged along the entire height of its walls from the sole of the base. The distance between the seams is determined by calculation and depends on the magnitude of the influencing loads, the type of soil, the material for the walls, functional purpose premises, etc. For brick buildings, the step is from 15 to 30 m, for wooden buildings - up to 70 m. In addition, compensating gaps should also be present at the boundaries of building parts that have different technical purposes, since the greatest stress occurs there.

The expansion joint in the foundation slab is a gap that separates it into separate blocks. It is filled with tow impregnated with resin.

One of the components of the foundation is the blind area. It also needs compensating gaps, because if it is unevenly subsided and the movement of soils, this element can simply break, which will lead to the wetting of the base walls. The blind area will cease to fulfill its protective function. Seams are arranged in increments of up to 2 meters, wooden slats are laid in them and poured on top with hot bitumen or other polymer that provides reliable waterproofing.

The junction of the blind area and the foundation wall necessarily has a movable seam. Usually its role is played by the waterproofing finish of the outer wall of the base.

Expansion joints in the wall

Vertical structures are exposed to several deformation loads at once. They are affected by precipitation during operation, temperature effects (seasonal and with a simultaneous temperature difference between the outer and inner parts in cold weather), the load from top coat, snow masses. Therefore, when calculating the expansion joint in the wall during design, it is important to take into account all the effects and arrange divisions that will not allow the structure to collapse.

AT modern construction use a wide variety of materials and methods for the construction of walls, which are:

- prefabricated block and brick;

- monolithic concrete / reinforced concrete;

- prefabricated panel;

- combined.

In all of them, destructive effects occur, and the stronger and harder the material, the greater the deformation loads appear in the structure. The division of the wall into blocks using expansion joints allows individual parts to deform at certain intervals without the threat of destruction of the entire element, within which no dangerous stress occurs.

Design and installation of expansion joints in vertical structures

For internal and external walls, the gap spacing is calculated differently; this is done at the design stage. The height of the walls is divided into compartments along the entire height, arranging expansion joints between them. The distance between them for load-bearing walls after calculations is from 20 m, for internal partitions - up to 30 m. The location of expansion joints in places of maximum stress allows you to remove these very stresses. As mentioned earlier, temperature and shrinkage joints occur in the above-ground part of the house and basically coincide, are located in places of the greatest concentration of temperature differences - at the corners of the outer walls. Expansion joints that compensate for sedimentary effects are arranged along the entire height of the wall to the base of the foundation and are evenly distributed along the length of the building.

An important nuance in the design of joints in the walls is their filling and design, since they are located on the visible parts of any building, especially if additional cladding is not implied.

Temperature expansion joints are arranged in the horizontal plane of the wall. In the process of erection, a tongue is placed in the masonry, which is covered with roofing paper in 2 layers and clogged with tow. close the seam clay castle. These materials do not react to temperature changes, thereby compensating for the deformation of the wall. With manual laying, the seal is invisible and does not require additional cladding.

In modern construction, profiles for expansion joints are increasingly being used. The advantage of using them is a special design that reinforces the gap in the wall. This prevents the appearance of cracks in the area of the expansion joint in the process of exposure to destructive loads. In addition, there are inserts made of hydrophobic materials in the body of the profile, which prevents moisture from entering the wall material and its further destruction. The design of the outer part of the expansion joint is made in such a way that it fits perfectly into any facade. A large assortment of the proposed profiles allows you to choose the most suitable design for any building.

Seams in horizontal slabs

When installing monolithic floor slabs, expansion joints must be made, since concrete is a rigid inelastic material and is subject to destruction as a result of various loads and simultaneous subsidence of the entire volume of the building. With the help of calculations, the width of one floor block is determined, and according to this parameter, interfloor elements are poured. Seams are filled with waterproofing materials and seals.

Seams in concrete floors

Floors constantly take the load from interior items, equipment, and their coatings are constantly subject to wear. In one room, floors of different materials can be arranged, which during operation do not seem to react to the incoming load, humidity and other influences. Such areas also need to be divided, like a monolithic concrete floor.

By appointment, expansion joints in concrete floors are divided into 3 main types.

- The insulating joint has a round or square shape, separates the floor from walls, columns and other internal vertical structures, from their impact in order to avoid deformation floor covering. When it is constructed, the entire perimeter is laid with polymer insulation and a concrete floor is poured inside the resulting contour.

- The shrinkage joint is designed to prevent cracking of concrete during hardening and operation. It is arranged in two ways: with the help of slats that form seams, which are inserted into the material until it loses plasticity; cutting and device after final surface treatment.

- The structural seam is performed at the boundaries of the shifts in the pouring of the floor sections. He has complex view tongue-and-groove connections and allows concrete to move in a horizontal plane and does not allow changes in adjacent sections.

Expansion joints in floors are gaps that divide the surface into several blocks or sections. In the vast majority, various profile structures are used for the construction of expansion joints.

The main types of profiles for the device of joints in the floors are as follows.

- Embedded - aluminum systems built into the plane of the floor covering. They are used in dry industrial premises with high traffic, regularly exposed to heavy equipment, machinery and special equipment. The profile can be reinforced with a rubber insert, it can have a decorative stainless steel overlay.

- Overhead. These systems are installed at the junction different coatings. They are a seam. Such profiles also withstand heavy loads from machinery and a large number of people. With increased load, the profile can be reinforced with polymer inserts.

- Waterproof profile systems are designed not only to compensate for deformation loads, but also to protect the floor cut from moisture and water ingress in rooms with little waterproofing or in open areas, parking lots, warehouses, etc. Such profiles are made of stainless steel, have in their design special gaskets PVC or rubber.

- Dividing systems are soft or hard PVC profiles. They are arranged as expansion and expansion joints in monolithic floors for various purposes. PVC profiles seal and protect floor joints, they are resistant to temperatures, acids and detergents, which makes them universally applicable. Expansion joints in concrete floors are sometimes filled with polymer mastics. PVC systems are the most functional and durable, so they should be preferred.

Technology for dividing joints in floors

Concrete floors are poured not at once the entire area, but in parts, in several stages. Separation joints must be arranged at the junctions of different sections of the pour, since the concrete may have different properties. Often, before pouring, the perimeter of the site is limited with insulating materials, which will later serve as a seal for the joints formed. If the pouring area is large, then the seams can be cut already in the finished floors. The size of the gaps and the distance between them is calculated based on the size of the coefficient of linear expansion of concrete. The average width of the seam is 12-20 mm, the distance between the cuts is 1.5 m. The depth reaches 2-3 cm. Separation is carried out using special equipment. The seams cut on the finished floor are filled with special seals and sealed with wear-resistant polymers or specialized profiles are built into them.

Seams at the joints of buildings

Often, additional buildings are added to existing buildings: in view of saving space within the city or ease of use in private. Outbuildings can have various purposes: retail space, office space, baths, garages, outbuildings. Almost always, the settlement of the main and additional buildings occurs in different ways. To avoid the troubles associated with this phenomenon, it is necessary to arrange an expansion joint between buildings.

Gaps between buildings compensate for all types of impacts: sedimentary, shrinkage, temperature, seismic. Since the main and attached buildings have one common wall, they organize expansion joint, which combines the protection function against all incoming loads.

Also, a gasket between the walls is needed when the material is heterogeneous: for example, the original structure is stone, and the additional one is wooden. In this case, the seam can be made from waterproofing material without additional structures.

If the foundation for the extension was not calculated immediately, but is being built additionally, it is imperative to separate it from the main one with a seam, because its design may differ. In this case, shrinkage and sedimentation of the base itself and the supported structure will occur.

An expansion joint is arranged along the entire height of the adjoining building.

Expansion joint- designed to reduce loads on structural elements in places of possible deformations arising from fluctuations in air temperature, seismic events, uneven ground settlement and other influences that can cause dangerous own loads that reduce the bearing capacity of structures. It is a kind of section in the building structure, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For the purpose of sealing, it is filled with an elastic insulating material.

Reinforced concrete structures deform with temperature changes - they shorten or lengthen, and due to concrete shrinkage they only shorten. With different draft in the vertical direction, parts of the structures are displaced.

Reinforced concrete structures are, in most cases, statically indeterminate systems, and therefore, from temperature changes, concrete shrinkage, and uneven foundation settlement, additional forces arise in them, which can lead to cracks or breakdown of parts of the structure.

In order to reduce the efforts from temperature and shrinkage, reinforced concrete structures are divided in length and width into separate parts (blocks) expansion joints. If the distance between expansion joints does not exceed the limits specified in the table below, then for conventional structures, as well as prestressed 3rd category crack resistance, temperature and shrinkage calculations can be omitted.

The largest distances between expansion joints in reinforced concrete structures in m, allowed without calculation

Construction type |

Inside heated buildings or in the ground, m |

In open structures and in unheated buildings, m |

Prefabricated frame, including mixed with metal and wooden floors |

60 |

40 |

Prefabricated solid |

50 |

30 |

Monolithic frame made of heavy concrete |

50 |

30 |

The same, from lightweight concrete |

40 |

25 |

Monolithic solid from heavy concrete |

40 |

25 |

Same, lightweight concrete |

30 |

20 |

For prestressed structures of the 1st and 2nd categories of crack resistance, the distance between expansion joints must in all cases be established on the basis of structural analysis

for crack resistance.

expansion joints, to ensure free deformation of parts of the structure, they are carried out along the entire height of the building - from the roof to the top of the foundation, while separating floors and walls. Usually expansion joint make it 2-3 cm wide, filling it with roofing felt, roofing felt (in several layers) or tarred tow.

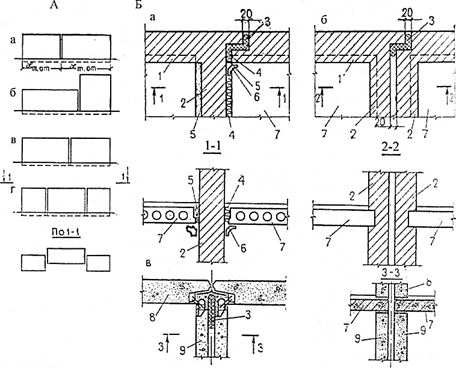

The most correct and clear expansion joint both in prefabricated and monolithic structures, it is created by the installation of paired columns and paired beams along them (Fig. 1, a, b).

This stitch is very handy. frame buildings, especially for heavy or dynamic loads on floors.

Sedimentary seams are arranged between parts of buildings based on soils of different quality or very different in height. Such seams are also carried out through the foundations. When reconnected

the building being erected to the old sedimentary seams are also necessary.

Good constructive solution sedimentary seam is achieved by the installation of counter beam consoles and the corresponding expansion of paired columns based on independent foundations (Fig. 1, c).

It is possible to arrange an inset span of slabs and beams between the two parts of the buildings (Fig. 1, d). With the structures described sedimentary seam the difference in foundation settlements does not cause stress or damage to parts of the building.

In monolithic (overlappings are possible temperature-shrink seams, arranged by freely supporting the end of the beam of one part of the building on the console formed by the continuation of the beam of the other part (Fig. 2, a). With such seams, in order to avoid damage to the consoles due to friction, careful execution of the contacting parts is necessary.

Detail of reinforcement by welded frames of beam consoles expansion joint shown in fig. 2b.

expansion joints should be provided in channels and tunnels, the distances between expansion joints are determined by calculation, but not less than 50 m. See below for examples of expansion joints.

To these nodes, you can add a small note on the installation of keys.

Installing keys expansion joint produced strictly in accordance with the design documentation.

It is required to provide a gap between the body of the key and the reinforcement of at least 20 mm. Fasten the dowels to the reinforcement using a tie wire. Ensure the fastening step is at least 250 mm. Connect the keys along the length using cyanoacrylate adhesives reinforced with RiteLok RT 3500 W or RiteLok RT 3500 V rubbers. In the production of any subsequent work, provide for measures to maintain the integrity of the structure expansion joint.

The device of the expansion joint in the collector of reinforced concrete prefabricated elements.

The outer walls, and together with the rest of the building structures, if necessary and depending on the specifics of the building solution, natural-climatic and engineering-geological conditions of construction, are dissected expansion joints various types:

- temperature,

- sedimentary,

- seismic.

An expansion joint is used to reduce loads on various structural elements in places of possible deformations that occur during seismic events, temperature fluctuations, uneven ground settlement, as well as other influences that can cause their own loads that reduce the bearing capacity of the structure.

This is a cut in the structure of the building, which divides the structure into separate blocks, which gives the structure a certain degree of elasticity. For sealing, it is filled with elastic insulating material.

Expansion joints are used depending on the purpose. These are temperature, anti-seismic, sedimentary and shrinkage. Temperature joints divide the building into compartments, from ground level to the roof inclusive. This does not affect the foundation, which is located below ground level, where it experiences temperature fluctuations to a lesser extent, and therefore does not undergo significant deformations.

Some parts of the building may have different number of storeys. Then the foundation soils, which are located under various parts buildings, perceive various loads. This can lead to cracks in the walls of the building, as well as in other structures.

Also, differences in the composition and structure of the foundation within the building area of the building can affect the uneven settlement of soils of the base of the structure. This can cause the appearance of sedimentary cracks even in a building of the same number of storeys, with a considerable length.

Sedimentary seams are made to avoid dangerous deformations. They differ in that when cutting the building along the entire height, the foundation is also included. Sometimes, if necessary, sutures are used. different types. Can be combined into temperature-sedimentary seams.

Anti-seismic joints are used in buildings constructed in an earthquake-prone area. Their peculiarity is that they divide the building into compartments, which are structurally independent stable volumes.

In walls that are built from monolithic concrete various kinds shrinkage seams are made. When concrete hardens, monolithic walls decrease in volume. The seams themselves prevent the occurrence of cracks, which reduce the bearing capacity of the walls.

Expansion joint- designed to reduce loads on structural elements in places of possible deformations arising from fluctuations in air temperature, seismic events, uneven ground settlement and other influences that can cause dangerous own loads that reduce the bearing capacity of structures. It is a kind of section in the building structure, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For the purpose of sealing, it is filled with an elastic insulating material.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Temperature joints they divide the building into compartments from ground level to the roof inclusive, without affecting the foundation, which, being below ground level, experiences temperature fluctuations to a lesser extent and, therefore, does not undergo significant deformations. The distance between the expansion joints is taken depending on the material of the walls and the estimated winter temperature of the construction area.

Separate parts of the building can be of different heights. In this case, the base soils located directly under different parts of the building will perceive different loads. Uneven deformation of the soil can lead to cracks in the walls and other building structures. Another reason for uneven subsidence of the foundation soils of a structure can be differences in the composition and structure of the foundation within the building area of the building. Then, in buildings of considerable length, even with the same number of storeys, sedimentary cracks may appear. Sedimentary seams are arranged in buildings to avoid the appearance of dangerous deformations. These seams, unlike temperature seams, cut buildings along their entire height, including foundations.

If it is necessary to use expansion joints of different types in one building, they are combined, if possible, in the form of so-called temperature-settlement joints.

Anti-seismic seams used in buildings under construction in areas prone to earthquakes. They cut the building into compartments, which in a constructive sense should be independent stable volumes. Along the lines of anti-seismic seams, double walls or double rows of load-bearing posts are included in the system of the load-bearing frame of the corresponding compartment.

Shrink seams are made in walls erected from various types of monolithic concrete. Monolithic walls during hardening of concrete are reduced in volume. Shrinkage joints prevent the occurrence of cracks that reduce the bearing capacity of the walls. During the curing process monolithic walls the width of the shrinkage seams increases; at the end of the shrinkage of the walls, the seams are tightly sealed.

Various materials are used to organize and waterproof expansion joints:

- sealants

- putties

- waterstops

Expansion joint- a vertical gap filled with elastic material, dismembering the walls of the building. Its purpose is to prevent the appearance of cracks from temperature differences and uneven settlement of the building.

|

|

|

Expansion joints in buildings and their outer walls: |

|

Thermal shrinkage seams arrange in order to avoid the formation of cracks and distortions in the walls caused by the concentration of efforts from exposure to variable air temperatures and shrinkage of materials (masonry, concrete). Such seams cut only the ground part of the building.

In order to avoid the appearance of cracks caused by shrinkage deformations in walls made of cast concrete and from concrete stones, as well as from unseasoned silicate brick(at the age of up to three months) it is recommended to lay structural reinforcement with a total cross section of 2-4 cm2 for each floor along the perimeter of the building at the level of window sills and lintels.

The seams in the walls associated with metal or reinforced concrete structures must match the seams in the structures.

Maximum allowable distances (in m) between expansion joints in the walls of heated buildings

| Estimated winter outside temperature (in degrees) | Masonry of baked bricks, ceramics and large blocks of all types on brand mortars | Laying of silicate bricks and ordinary concrete stones on brand mortars | Masonry from natural stones on brand solutions | ||||||

| 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | |

| below - 30 | 50 | 75 | 100 | 25 | 35 | 50 | 32 | 44 | 62 |

| from 21 to - 30 | 60 | 90 | 120 | 30 | 45 | 60 | 38 | 56 | 75 |

| from 11 to - 20 | 80 | 120 | 150 | 40 | 60 | 80 | 50 | 75 | 100 |

| from 10 and above | 100 | 150 | 200 | 50 | 75 | 100 | 62 | 94 | 125 |

The distances indicated in the table are subject to reduction: for the walls of closed unheated buildings - by 30%, for open stone structures - by 50%

With a change in temperature, reinforced concrete structures are deformed: they are shortened or lengthened, and due to concrete shrinkage, they are shortened. With uneven subsidence of the base in the vertical direction, parts of the structures are mutually displaced.

Reinforced concrete structures, as a rule, are statically indeterminate systems in which, with temperature changes, the development of shrinkage deformations, and uneven settlement of foundations, additional forces arise that can cause cracking. To reduce this kind of effort in buildings of great length, temperature-shrinkage and sedimentary seams are necessary.

Reinforced concrete structures, as a rule, are statically indeterminate systems in which, with temperature changes, the development of shrinkage deformations, and uneven settlement of foundations, additional forces arise that can cause cracking. To reduce this kind of effort in buildings of great length, temperature-shrinkage and sedimentary seams are necessary.

In coverings and ceilings of buildings, the distance between the seams depends on the flexibility of the columns and the flexibility of the joints; in monolithic structures, this distance should be less than in prefabricated ones. With the installation of rolling supports, thermal stresses can be generally avoided.

In addition, the distance between the expansion joints depends on the temperature difference; therefore, in heated buildings these distances are smaller regardless of all other factors.

Temperature-shrinkage joints cut through structures from the roof to foundations, and sedimentary joints completely separate one part of the structure from another. The temperature-shrinkage joint can be formed by the installation of paired columns on a common foundation. Sedimentary joints are provided in places of a sharp difference in the height of buildings, the junction of newly erected buildings with old ones during the construction of buildings or structures on soils of different composition and in other cases when uneven settlement of foundations is possible.

Sedimentary seams also form a device of paired columns, but installed on separate foundations.

|

|

|

Expansion joints: a - the building is separated by an expansion joint; b - the building is separated by a sedimentary seam |

Expansion joints: 1 - expansion joint; 2 - sedimentary seam; 3 - inset span of the sedimentary seam |

Distances between temperature-shrinkage joints in concrete and reinforced concrete structures low structures are allowed to be accepted constructively, without calculation.

|

|

|

The device of sedimentary (deformation) seams along the perimeter of the building envelope: 1 - entrance group; 2 - decorative blind area; 3 decorative path made of outdoor stones; 4 - lawn; 5 - semi-closed drainage; 6 - blind area made of monolithic concrete; 7 - expansion joints with wooden bookmarks (short boards); 8 - wall of the house; 9 - semi-closed (open) drainage in the form of a tray; 10 - sedimentary (deformation) seam between the base of the house and the base entrance group; 11 - windows |

|

|

|

|

|

General view of the structure of the sedimentary (deformation) joint along section 1-1: 1 - pebbles (crushed stone, sand); semi-closed drainage (cut asbestos-cement pipe) resistant flat stones; 4 - pre-compacted base soil; 5 - sand cushion height from 8 to 15 cm; 6 - a layer of pebbles or crushed stone 5-10 cm; 7 - short board; 8 - pipe of closed bypass drainage; 9 - bed-bed stone; 10 - basement of the building; 11 - foundation; 12 - rammed base; 13 possible level of groundwater rise; 14 - a blind area made of monolithic concreteThe end of the form |

|

Sedimentary seams divide the building along the length into parts to prevent the destruction of structures in the event of a possible uneven settlement separate parts. Sedimentary joints run from the eaves of the building to the base of the foundation, the location of the joints is indicated in the project. The seams in the walls are made in the form of a sheet pile, as a rule, 1/2 brick thick, with two layers of roofing; and in the foundations - without tongue and groove. Above the upper edge of the foundation under the sheet pile of the wall, a gap of 1-2 bricks is left so that during the draft the sheet pile does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

Sedimentary seams divide the building along the length into parts to prevent the destruction of structures in the event of a possible uneven settlement separate parts. Sedimentary joints run from the eaves of the building to the base of the foundation, the location of the joints is indicated in the project. The seams in the walls are made in the form of a sheet pile, as a rule, 1/2 brick thick, with two layers of roofing; and in the foundations - without tongue and groove. Above the upper edge of the foundation under the sheet pile of the wall, a gap of 1-2 bricks is left so that during the draft the sheet pile does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

So that surface groundwater does not penetrate into the basement through the sedimentary seam, with its outer side arrange a clay castle or apply other measures provided for by the project. Expansion joints protect buildings from cracks during thermal deformations.

Sedimentary seams are arranged at the junctions of building sections:

- located on heterogeneous soils;

- attached to existing buildings;

- with a difference in height exceeding 10 m;

- in all cases where uneven settlement of the foundation can be expected.

Sedimentary and temperature joints in brick walls should be made in the form of a tongue and groove with a groove size for walls with a thickness of 1.5 and 2 bricks - 13 x 14 cm, and for thicker walls 13 x 27 cm. In rubble masonry of basement walls and foundations, seams can be arranged through.

On device expansion joints of the coating roofing carpet best to break. Rolled rubber can be used as a vapor barrier in the design of the expansion joint.

|

|

|

Expansion joint |

Scheme of installation of a deformation-sedimentary joint between sections of a retaining wall |

In cases where the expansion joint is arranged in the places of the watershed, and the movement of water flow along the seam is impossible, or the slopes on the roof are more than 15%, then it is permissible to use a simplified design of the expansion joint during the device. The deformations of the building are compensated by the upper mineral wool insulation.

In roofs with a corrugated sheet base, it is necessary to fix the main layers roofing material on the edges expansion joint.

Thermal expansion joint with walls made of lightweight concrete or piece materials can be installed in roofs with concrete base or from reinforced concrete slabs.

|

|

|

Simplified expansion joint design |

Expansion joint in roofs with corrugated sheet base |

The wall of the expansion joint is installed on bearing structures. The edge of the wall of the TDSH should be 300 mm higher than the surface of the roofing carpet. The seam between the walls must be at least 30 mm.

A metal compensator installed in an expansion joint cannot serve as a vapor barrier. It is necessary to lay additional layers of vapor barrier material on the compensator.

Temperature joint arrange in walls of great length to avoid the appearance of cracks from temperature changes. Such a seam cuts through structures only on the ground part, up to the foundations, because the foundations, being in the ground, do not experience temperature effects. The distance between these seams ranges from 20 to 200 m and depends on the material of the walls and the area of construction. The smallest joint width is 20 mm.

|

|

| The device of a temperature-strain joint in the partitions of the building: 1 - masonry of small cellular concrete blocks; 2, 3 - cellular concrete floor slabs; 4 - seam with thermal insulation board(the presence of fragments in the seam is unacceptable wall material and glue); 5 - seam in the foundation; 6 - reinforced belt along the perimeter of the building; 7 - reinforced concrete slab grounds; 8 - reinforced belt along the perimeter of the building with external thermal insulation; 9 - roof with thermal insulation according to the rules of roofing | Vertical expansion joint: 1 - outer facing plates; 2 - hydrowindproof layer; 3 - plaster system; 19 - profile for a vertical expansion joint; 23 - wooden frame racks; 30 - insulating material |

Sedimentary seam cuts the building to its full height - from the ridge to the base of the foundation. Such a seam is located depending on some factors:

with a height difference of the building not less than 10m;

if the soils that are used as a base have different bearing capacity;

during the construction of a building with a different erection period.

The smallest joint width is 20 mm

seismic seam suit in buildings that are built in seismic areas.

Scheme of placement and design of expansion joints: a - facade of the building; b - temperature or sedimentary seam with a groove and a crest; c - temperature or sedimentary seam in a quarter; d - expansion joint with a compensator; 1 - temperature seam; 2 - sedimentary seam; 3 - wall; 4 - foundation; 5 - insulation; 6 - compensator; 7 - roll insulation.

The designs of expansion joints should provide the possibility of moving the ends of the spans without overvoltage and damage to the elements of the joint, the rider's clothing, canvas and spans; must be water and dirt impervious (to exclude water and dirt from entering the ends of the beams and support platforms); operable in the specified temperature ranges; have reliable anchoring in the span; prevent the penetration of moisture on the roadway slab and under the border (have a reliable waterproofing).

The designs of expansion joints should provide the possibility of moving the ends of the spans without overvoltage and damage to the elements of the joint, the rider's clothing, canvas and spans; must be water and dirt impervious (to exclude water and dirt from entering the ends of the beams and support platforms); operable in the specified temperature ranges; have reliable anchoring in the span; prevent the penetration of moisture on the roadway slab and under the border (have a reliable waterproofing).

The material of constructions of expansion joints must resist wear, ular and abrasion, the effects of ice, snow, sand; should be relatively immune to the effects of sunlight, oil products, salts.

In general, expansion joints should be located:

- between the foundation and wall masonry using bituminous roll materials;

- between warm and cold walls;

- when changing the thickness of the wall;

- in unreinforced walls with a length of more than 6 m (longitudinal reinforcement of the walls makes it possible to increase the distance between expansion joints);

- when crossing long load-bearing walls;

- at the junctions with columns or structures made of other materials;

- in places of a sharp change in the height of the wall.

Sealing expansion joints

Expansion joints are sealed with mineral wool or polyethylene foam. From the side of the room, the seams are sealed with elastic vapor-tight materials, with outside– weatherproof sealants or flashings. The cladding material must not overlap the expansion joint.

The dimensions of the temperature blocks are taken depending on the type and design of buildings. The largest distances (m) between expansion joints in frame buildings that can be allowed without verification calculation.

In addition to temperature deformations, the building can give uneven settlement if it is located on inhomogeneous soils or in the case of a sharply different operational load along the length of the building. In this case, to avoid sedimentary deformations, arrange sedimentary seams. At the same time, the foundations are made independent, and in the above-ground part of the building, the sedimentary seam is combined with a temperature seam or with an abutment seam (adjacency of buildings of different heights, an old building to a new one). expansion joints arrange in walls and coatings in order to ensure the possibility of mutual displacement of adjacent parts of the building both in horizontal and vertical directions without violating the thermal resistance of the seam and its waterproofing properties.

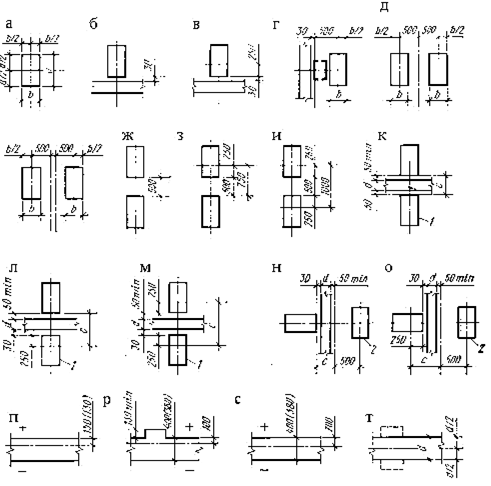

When arranging longitudinal expansion joints or height difference of parallel spans on paired columns, paired modular coordination axles with an insert between them should be provided. Depending on the size of the binding of the columns in each of the adjacent spans, the dimensions of the inserts between the paired coordination axes along the lines of the expansion joints in buildings with spans of the same height and with coverings along the rafters (trusses) are taken equal to 500, 750, 1000 mm.

|

|

|

Binding of columns and walls of one-story buildings to coordinate axes: a - binding of columns to the middle axes; b, c - the same, columns and walls to the extreme longitudinal axes; d, e, f - the same, to the transverse axes at the ends of buildings and places of transverse expansion joints; g, h, i - binding of columns in the longitudinal expansion joints of buildings with spans of the same height; k, l, m - the same, with a difference in heights of parallel spans, n, o - the same, with mutually perpendicular junction of spans; p, p, s, t - binding of load-bearing walls to longitudinal coordinate axes; 1 - columns of elevated spans; 2 - columns of low spans, which adjoin the ends to an increased transverse span |

|

The size of the insert between the longitudinal coordination axes along the line of height difference of parallel spans in buildings with roof beams (trusses) coatings must be a multiple of 50 mm:

- binding to the coordination axes of the faces of the columns facing the drop;

- wall thickness of panels and a gap of 30 m between its inner plane and the edge of the columns of an increased span;

- a gap of at least 50 mm between the outer plane of the wall and the edge of the low-span columns.

In this case, the size of the insert must be at least 300 mm. The dimensions of the inserts at the junction of mutually perpendicular spans (lower longitudinal to higher transverse) range from 300 to 900 mm. If there is a longitudinal seam between spans that are adjacent to a perpendicular span, this seam is extended into the perpendicular span where it will be a transverse joint. In this case, the insertion between the coordination axes in the longitudinal and transverse seams is 500, 750 and 1000 mm, and each of the paired columns along the line of the transverse seam must be displaced from the nearest axis by 500 mm. If the coating structures are supported on the outer walls, then the inner plane of the wall is shifted inward from the coordination axis by 150 (130) mm.

Columns to the average longitudinal and transverse coordination axes multi-storey buildings tied so that the geometric axes of the section of the columns coincide with the coordination axes, with the exception of the columns along the lines of expansion joints. In the case of binding columns and external walls made of panels to the extreme longitudinal coordination axes of buildings, the outer edge of the columns (depending on the frame design) is shifted outward from the coordination axis by 200 mm or aligned with this axis, and a gap of 30 is provided between the inner plane of the wall and the faces of the columns. mm. Along the line of transverse expansion joints of buildings with ceilings made of prefabricated ribbed or smooth multi-hollow slabs, paired coordination axes are provided with an insert between them of 1000 mm in size, and the geometric axes of the paired columns are combined with the coordination axes.

In the case of an extension of multi-storey buildings to single-storey buildings, it is not allowed to mix the coordination axes perpendicular to the extension line and common to both parts of the interlocked building. The dimensions of the insert between the parallel extreme coordination axes along the building extension line are assigned taking into account the use of standard wall panels - elongated ordinary or additional ones.

If there are expansion joints of double walls in places of expansion joints, double modular centering axes are used, the distance between which is taken equal to the sum of the distances from each axis to the corresponding wall face with the addition of the joint size.