Calculation of supply air to the room. Fan selection and calculation

- Exhaust ventilation in the kitchen

- Fan power calculation

- Air change rate

- Another way to determine the power of the device

Nowadays it is impossible to imagine our life without ventilation systems. They are installed in industrial buildings, in offices, in educational institutions, in shops, in apartments. The operation of these systems is unthinkable without the use of exhaust fans of various capacities. A widely used element of apartment ventilation is a kitchen hood. She may have various forms, sizes, design.

The amount of purified air in the room will depend on the calculation of the power of the kitchen hood fan.

Exhaust ventilation in the kitchen

But external beauty is not the most important thing. The main task of this appliance is to rid the kitchen of odors, burning, soot and grease that appear during cooking. Exhaust ventilation removes fumes from different kind heating appliances. It prevents the appearance of dirty plaque on the ceiling and on the surface of the walls. This allows you to perform redecorating much less often, which will save a significant amount of money. Less time will be needed for general cleaning.

A device capable of passing a certain amount of air through its filters can cope with the task of cleaning the atmosphere in the room. And for this you need to choose a device with a fan of the required power. How to calculate the power of the device?

Back to index

Fan power calculation

An example of calculating the performance of a kitchen hood fan.

- Using a tape measure, measure the size of the kitchen and determine its volume in meters. To do this, multiply the length by the width and height. The BTI documents indicate the area of \u200b\u200bthe premises. Example: the kitchen area is 10 m². The height from floor to ceiling is 3 m. We multiply the area by the height and get 30 m³. This is the size of the kitchen.

- Next, the value characterizing the air exchange is calculated. To do this, multiply the volume of the kitchen by the number of complete air updates per hour. Building codes and regulations (SNiP) provide for an air exchange rate of 10-12. So to calculate the power exhaust system you need to multiply 30 m³ by 12. The result is a figure of 360 m³ / h. So much air must be renewed every hour.

- To carry out the exchange in such a volume, a fan with a capacity of 400-800 m³ / h is needed. But standard ventilation ducts able to pass only about 180 m³. Therefore, the fan will not help much here.

- In this case, the recirculation hood system will help, which passes the air through the filters and sends it back to the room. Power is also required to overcome the resistance of the filters. Therefore, 40% should be added to the calculated figure. It will turn out 560-1120 m³. This should be the power of the hood fan in a 30 m³ kitchen.

- In some cases, you can do without a ventilation duct. To do this, the exhaust fan is installed in a specially equipped opening in the wall, in the ceiling or at the junction of the ceiling and wall. This installation allows the use of a less powerful fan.

Hood power for different rooms.

This is just a simple calculation of the required power of the exhaust fan. If the kitchen does not have doors, then the volume of the adjacent room must also be taken into account. So, the formula for calculating the fan power for general cases is: room width x length x height x exchange rate = desired value. You can calculate the volume of the room without any problems. It is enough to measure the length, width and height and multiply them.

Back to index

Air change rate

Multiplicity for rooms different type is defined like this:

Table for calculating the minimum hood performance in relation to the volume of the kitchen.

The highest multiplicity is chosen for use in rooms with many people, with high humidity and temperature, with large quantity dust and strong odors. In a kitchen with an electric hob, you can choose a lower indicator, with a gas stove - a larger one. This is due to the fact that when the stove is turned on, the gas emits combustion products. The fan, selected taking into account the above data, can be mounted in the wall, window, ceiling of the room.

The range of kitchen hoods for stoves is huge, there are models different forms and sizes. But appearance in this technique is not the main thing. More important technical specifications power and volume of pumped air. Functionality is more important than aesthetics. Only a competent engineer can accurately calculate the performance of a kitchen hood. However, when selecting exhaust equipment for apartments and private houses, simplified formulas are often used. Let's consider how to use them correctly and adequately interpret the results of calculations.

When cooking on the stove, fumes, soot, pleasant and not very smells are inevitably formed. From all this kitchen room must be disposed of immediately, otherwise you can forget about a comfortable microclimate and cleanliness in the kitchen. You will have to spend a lot of effort on washing the hob and the walls around from grease deposits, and also keep the windows open all the time for ventilation.

Kitchen hood must be beautiful, productive and larger than the area of the hob

For bakeries and food preparation shops, a range hood is a must. In a cottage or apartment, its installation is left to the discretion of the owners. By building codes residential buildings are equipped with natural or forced ventilation. However, even for small kitchen this air exchange system is often not enough.

Household hoods for the kitchen consist of:

- corps;

- electric motor;

- fan;

- air purifying filters;

- lighting elements.

They can operate in pull and recirculation mode. In the first case room air sucked out of the room, being replaced by new ventilation system. And in the second, it is pumped through internal carbon filters and returned to the room already cleaned.

Important! Connecting the hood to existing ventilation ducts may disrupt its operation, not all ducts are designed for increased load.

For purely exhaust equipment, it is necessary to equip the outlet to the ventilation duct, which does not always look aesthetically pleasing. Plus, for her effective work continuous flow required fresh air from the outside. Equipment with recirculation is easier to install, but its carbon filters will have to be changed at least once a year.

A variety of designs of exhaust technology for cookers

It should be clearly understood that, regardless of the model and power, the kitchen hood is designed to purify and remove polluted air exclusively from the surface of the stove. The space under the ceiling is not available to her, so it is so important to select ventilation equipment according to size. hob.

The performance of the hood is calculated in cubic meters / hour - this is the volume of air that it is able to pump through itself. Power is measured in kilowatts, which reflects the amount of electricity consumed during operation. These two values should not be confused.

Norm Requirements! The performance of the exhaust equipment should be such that in an hour all the air in the kitchen of an apartment or a private house is renewed at least ten times.

According to SNiPs at work ventilation equipment, to which the hood also belongs, should completely renew the air in the room several times in an hour. For kitchens in residential buildings, this value is determined at 10–15. It depends on the type of stove, the mode of operation of the fan and other factors. To simplify the calculations, this coefficient is taken as 12.

How to calculate the power of exhaust equipment

The power indicators of the hood directly depend on its performance. The more it is able to pump air, the more powerful the fan is in it, which needs an electric motor to work.

For equipment connected to ventilation ducts, operating only in exhaust mode, the performance should be calculated based on the cross section of the air ducts. It is almost impossible to do this without engineering knowledge and a housing project. And the calculation of the exhaust power by area is suitable only for recirculation models. Unlike the first option, the size of the ventilation ducts does not affect their performance.

The simplest formula for calculating the area

The classic calculation of the performance of a kitchen hood is the multiplication of the square of the kitchen, its height and a factor of 12. However, the resulting figure is very conditional. It doesn't take into account many factors.

- cooking on an electric stove;

- kitchen room with closed doors and windows;

- rectangular kitchen without an abundance of decorative delights.

If a gas stove is used for cooking, then the coefficient 12 should be changed to 20 without hesitation. In this case, in addition to fumes, the hood will also have to remove gas combustion products from the kitchen. Plus, in any case, it is worth adding 15-20% in reserve.

Calculation of the performance of exhaust equipment by cubic capacity of the kitchen

Another 25-30% of the power must be added to carbon filter. It creates additional resistance for the passage of air flow.

Important nuance! Calculations of productivity and power for the hood should be made based on the area of \u200b\u200bthe kitchen itself and the rooms adjacent to it, if they are not fenced off from the first.

If the door to the kitchen is constantly open or there is an arch instead, then the parameters of the exhaust technology should be calculated based on the total quadrature of the adjacent room. The same applies to corridors, as well as combined living rooms or halls. The absence of barriers increases the amount of air being processed, as it constantly circulates between the kitchen and adjoining rooms.

Accounting for additional factors

The above performance calculation is based on a hood with recirculation. If the technique works in exhaust mode, sending the flow to the ventilation, then its efficiency is greatly affected throughput ventilation ducts. Of course, it is possible to increase the volume of air pumped through a narrow shaft due to increased power engine, however, this leads to an increase in noise from the running fan and overheating of the electric motor.

Approximate indicators of the required performance of the hood in the kitchen

In most private and apartment buildings ventilation ducts in the section do not exceed 125 mm, which allows pumping about 400 m 3 / h of air through them. If you install a hood of greater productivity in the kitchen, then there will be little sense from it. In addition, air ducts often have irregularities, narrowing and turns inside, which further reduces their throughput.

Important! The effectiveness of a kitchen hood depends on the mode of operation and the method of its installation, as well as the cubic capacity of the room, the type of stove and design features ventilation ducts.

If you follow a simplified calculation, then for a small kitchen, a low-power hood will suffice. However, formulas are formulas, and common sense never hurts. The smells from the stove fill a small room faster, and their concentration in this case turns out to be an order of magnitude higher than in spacious kitchen. For quite small room where food is prepared, it is necessary to select equipment more powerful than the calculated indicators.

Choice of kitchen hood: noise vs performance

With an increase in power, the noise of the exhaust system increases. Excessive noise will quickly tire the housewife, as a result, cooked food may turn out to be of little use for consumption.

Modern hood for home cooking during operation, it makes 40-45 decibel noise

Household hoods are equipped asynchronous electric motors, which, unlike power units in vacuum cleaners or drills, are much quieter. However, when they are turned on at full power, the noise becomes noticeable. Only at low and medium speeds they do not create unpleasant sensations.

Advice! Optimal extraction- This is a model with adjustable power and several modes of operation.

Completely silent kitchen appliances does not exist. Manufacturers are doing everything possible to reduce its noise, but they are far from omnipotent. At the same time, the noise intensity depends not only on the power of the electric motor and fan, but also on the cleanliness of the filters and air ducts. Without regular maintenance, the hood will bring instead of comfort only headache.

Video: how to choose a hood of optimal design and power

The kitchen hood is part of a forced ventilation system, so the calculation of its power and performance should be carried out together with the design of all ventilation. The above formulas will help you navigate the calculated and required numbers. For most home kitchens, this is sufficient. If you want maximum efficiency and stability in your work, then it is better to turn to professionals for accurate calculations.

Musty stale air in the living room, fumes and rich smells of food in the kitchen, exhausts and amber of fuels and lubricants in the garage - such conditions suggest that how to calculate draw power.

1

It is a mistake to think that it is to purify the air from unpleasant odors. Air fresheners work best for this. Ventilation should also serve to rid the premises of substances in suspension (such as fats, which otherwise settle on the surface of furniture, walls and ceilings), as well as combustion products and fumes. Often the fundamental criterion for choosing a hood that is connected to the ventilation system is not power, but quiet operation..

Productivity is also important, since it is expressed in how many times in a certain period of time the air in the room is completely updated. Yes, this concept is quite flexible, because opened door eliminates the complete isolation of the kitchen from the hallway or living room. Eventually air masses move freely, drawn by drafts, the movements of people and animals. In addition, as the room is ventilated during cooking in the kitchen or warming up the car engine in the garage, the air coming from the outside is polluted. But we will rely on the recommendations of the SES, according to which, within an hour in the same kitchen, the entire volume of air should be replaced at least 12 times. This thesis will serve as the basis for how to calculate the power of the hood.

Hood power calculator

Specify the size and type of the room.| Room type | Kitchen Bathroom Toilet |

Required performance: |

| Room |

m 2 X cm |

|

| Ceiling | cm |

2

Somewhat earlier, such a factor influencing the choice as the noise emitted by the exhaust system was mentioned. We should not forget about this property of turbines built into kitchen ventilation, because it directly depends on the power, that is, the number of revolutions per minute, as well as on the diameter of the channel and the number of elbows in it, the distance to the ventilation shaft, the density of filters and other trifles. Therefore, you always need to find a compromise between the desire to buy more powerful equipment and the desire to spend evenings in the kitchen in a cozy environment.

According to the facts, the comfortable noise threshold in the room is no more than 30 decibels (db), this is the so-called background noise - the distant roar of motors of cars passing along the street, birds chirping outside the window, the murmur of water in the pipes. At the lowest speed, a truly quiet hood emits no more than 35 dB, at the second speed - within 45, at the third - about 50 dB. When compared to household noise, this is equivalent to a whisper at 5 meters from you, a conversation at 10 meters and a quiet conversation at 3 meters, respectively. Accordingly, a noise threshold of 55 dB can be considered uncomfortable, given that there is always enough work in the kitchen.

If you do not pay attention to decibels, then the calculation of the hood is very simple. You have a certain volume of the room, the so-called cubic capacity, within these limits the air must be constantly updated, preferably at least 12 times per hour. So we first calculate the volume of the room, multiplying its length, width (this will give us the area) and height V=S. H, and then we multiply the result by the same 12 complete air purifications. However, this number of ventilations is usually calculated on the maximum load of the hood, that is, it will mean prohibitive noise in the kitchen during the same hour. Therefore, be sure to add at least 15% to the result of multiplications (ideally 30%) and get V. 12 . 15=P, that is, the power determined by cubic meters per hour (m 3 / h).

The choice of hood is largely influenced by the type of hob, due to the different amounts of combustion products emitted into the air. Yes, at electrical panel they are completely absent, as well as in induction, and in gas they take place, along with soot. Therefore, for the first two in the kitchen, 3x4 meters is enough minimum power 486 cubic meters per hour, and for the third at least 650 cubic meters of air in the same time. Accordingly, the coefficient of renewal of air in the room for electrical hobs taken as 15, and for gas 20 times per hour. It is logical that if the doorway is devoid of a closing sash and has turned into an arch, the power should be increased due to the spread of odors and combustion products, and for the same surfaces it will already be within 600 and 800 m 3 / h, respectively.

3

Unlike the kitchen, the room reserved for the car should be much better ventilated. And this is logical, since it is difficult to compare by the amount of combustion products released gas stove and an internal combustion engine. Therefore, before you calculate the hood, you need to decide which vehicles and in what quantity you will put there. The emissions of a car and a truck vary greatly in volume and content of harmful substances, especially if the former requires high-octane gasoline, and the latter quietly consumes diesel fuel. According to the air exchange standards established by ABOK, one a car it is necessary to provide air flow in the amount of 180 cubic meters per hour.

In addition, there must be an inlet opening that ensures the supply of fresh air in the proper volume. However, it is impossible to step over reasonable limits here, because otherwise the garage will simply get cold in winter. As a rule, for each square meter rooms add 25 square centimeters in cross section exhaust duct. Well, knowing the area, it will not be difficult to calculate the radius, based on the formula S = πR2, which will be transformed into R = √(S/π). It is better to locate the air outlet at the highest point of the garage, for example, through the roof, building up a pipe with a length of at least a meter. To prevent precipitation from entering the room, the upper end of the pipe must either be bent 90 degrees or covered with a special cap of the "fungus" type.

When arranging ventilation, it is necessary to minimize access to cold in the autumn-winter months, taking into account the recommendation of SNiP 21-02-99, maintain a temperature of at least 5 ℃ in the garage.

As for basements and other completely enclosed spaces, here you also need to remember about humidity. It can only be fought with enhanced high-quality ventilation, for which, when calculating the exhaust power, we take a factor of 20, corresponding to the amount of air exchange per hour. In addition to the above ratio of the area and cross section of the outlet channel, you can use another option - for each square meter there are about 15 millimeters of pipe diameter. In this case, it is desirable to make at least 2 knees in the outlet channel, since a straight pipe is an excellent cold bridge.

It is not recommended to make many bends, because the more there are, the stronger the noise of the exhaust system. In addition, each knee reduces ventilation efficiency by approximately 10%. In order for the air drawn out by the turbine to be replenished at the same speed, several inlet openings can be made by supplying them with retraction fans. The entrance channels are located closer to the floor, at a distance of 40 centimeters from it, and are covered with a fine mesh to prevent the penetration of rodents.

Fans general purpose used to work on clean air, the temperature of which is less than 80 degrees. Special heat-resistant fans are designed to move hotter air. For operation in aggressive and explosive environments, special anti-corrosion and explosion-proof fans are produced. The housing and parts of the anti-corrosion fan are made of materials that do not enter into chemical reaction with corrosive substances of the transported gas. Explosion-proof design eliminates the possibility of sparking inside the casing (casing) of the fan and increased heating of its parts during operation. To move dusty air, special dust fans are used. Fan sizes are characterized by a number that indicates the diameter of the fan impeller, expressed in decimeters.

According to the principle of operation, fans are divided into centrifugal (radial) and axial. Centrifugal fans low pressure create a total pressure of up to 1000 Pa; medium pressure fans - up to 3000 Pa; and high pressure fans develop pressure from 3000 Pa to 15000 Pa.

Centrifugal fans are made with disk and diskless impellers:

The impeller blades are mounted between two discs. The front disc is in the form of a ring, the rear disc is solid. The blades of the diskless wheel are attached to the hub. Volute centrifugal fan installed on independent supports, or on a frame common to the electric motor.

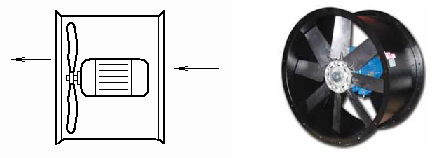

Axial fans are characterized by high performance, but low pressure, so they are widely used in general ventilation to move large volumes of air at low pressure. If the impeller axial fan consists of symmetrical blades, the fan is reversible.

Axial fan diagram:

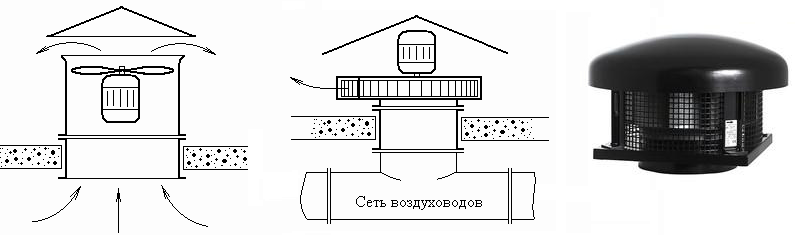

Roof fans are made axial and radial; are installed on roofs, on bare floors of buildings. The impeller of both axial and radial roof fans rotates in a horizontal plane. Schemes of operation of axial and radial (centrifugal) roof fans in:

Axial roof fans are used for general exchange exhaust ventilation without ductwork. Radial roof fans develop more high pressures, so they can work both without a network and with a network of air ducts connected to them.

Fan selection according to aerodynamic characteristics.

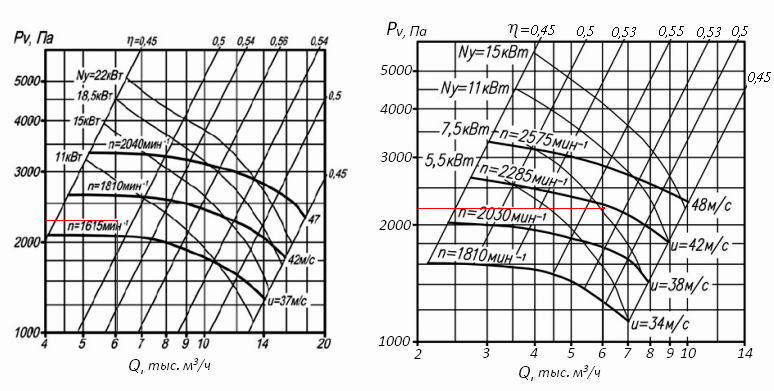

For each ventilation system, aspiration or pneumatic transport unit, the fan is selected individually, using the graphs of the aerodynamic characteristics of several fans. By pressure and air flow on each graph, a working point is found, which determines the efficiency and speed of the fan impeller. Comparing the position of the operating point on different characteristics, choose the fan that gives the greatest efficiency at given values of pressure and air flow.

Example. Calculation ventilation unit showed the total pressure loss in the system Hc = 2000 Pa at the required air flowQc=6000 m³/h. Choose a fan that can overcome this network resistance and provide the required performance.

To select a fan, its design pressure is taken with a safety factork=1,1:

Hb= kHc; Hb \u003d 1.1 2000 \u003d 2200 (Pa).

The air consumption is calculated taking into account all unproductive suctions.Q in = Qc=6000 (m³/h). Let us consider the aerodynamic characteristics of two close numbers of fans, in the operating range of which the values fall design pressure and air flow of the designed ventilation unit:

Aerodynamic characteristics of fan 1 and fan 2.

At the intersection of Rv=2200 Pa and Q\u003d 6000 m³ / hour we indicate the operating point. The highest efficiency is determined on the characteristic of fan 2: efficiency = 0.54; impeller speedn=2280 rpm; circumferential speed of the edge of the wheelu~42 m/s

Peripheral speed of the impeller of the 1st fan (u~38 m/s) is much less, which means that the noise and vibration generated by this fan will be less, and the operational reliability of the installation will be higher. Sometimes a slower fan is preferred. But the operating efficiency of the fan must be at least 0.9 of it. maximum efficiency. Let's compare two more aerodynamic characteristics that are suitable for choosing a fan for the same ventilation unit:

Aerodynamic characteristics of fan 3 and fan 4.

The efficiency of fan 4 is close to the maximum (0.59). The frequency of rotation of its impellern=2250 rpm. The efficiency of the 3rd fan is slightly lower (0.575), but the impeller speed is also significantly lower:n=1700 rpm. With a small difference in efficiency, the 3rd fan is preferable. If the drive and motor power calculations show close results for both fans, fan 3 should be selected.

Calculation of the power required to drive the fan.

The power required to drive the fan depends on the pressure it generatesHin (Pa), the volume of air movedQin (m³ / s) and efficiency coefficient:

N in = H in Q v/1000 efficiency (kW); Hb=2200 Pa; Qv=6000/3600=1.67 m³/sec.

Efficiencies of fans 1, 2, 3 and 4 pre-selected according to aerodynamic characteristics: 0.49; 0.54; 0.575; 0.59.

Substituting the value of pressure, flow and efficiency into the calculation formula, we obtain the following power values for the drive of each fan: 7.48 kW, 6.8 kW, 6.37 kW, 6.22 kW.

Calculation of electric motor power for fan drive.

The power of the electric motor depends on the type of its transmission from the motor shaft to the fan shaft, and is taken into account in the calculation by the corresponding coefficient (klane). There is no power loss when the fan impeller is directly seated on the motor shaft, i.e., the efficiency of such a transmission is 1. The efficiency of connecting the fan and motor shafts using a coupling is 0.98. To achieve the required speed of the fan impeller, we use a V-belt transmission, the efficiency of which is 0.95. Bearing losses are taken into account by the coefficientkn=0.98. According to the formula for calculating the power of an electric motor:

N email= N in / k lane k P

we get the following power: 8.0 kW; 7.3 kW; 6.8 kW; 6.7 kW.

The installed power of the electric motor is taken with a safety factorks=1.15 for motors with power less than 5 kW; for motors over 5 kWk h=1.1:

N y= k h N email

Taking into account the safety factorkh=1.1 final power of electric motors for the 1st and 2nd fans will be 8.8 kW and 8 kW; for the 3rd and 4th 7.5 kW and 7.4 kW. The first two fans would have to be equipped with an 11 kW motor, for any fan from the second pair, an electric motor power of 7.5 kW is enough. We select fan 3: as less energy-intensive than standard sizes 1 or 2; and as more low-speed and operationally reliable compared to fan 4.

Fan numbers and graphs of aerodynamic characteristics in the example of fan selection are taken conditionally and do not refer to any particular brand and standard size. (And they could.)

Calculation of the diameters of the pulleys of the V-belt drive of the fan.

V-belt transmission allows you to pick up desired frequency rotation of the impeller by installing pulleys of different diameters on the motor shaft and the fan drive shaft. The gear ratio of the rotational speed of the motor shaft to the rotational speed of the fan impeller is determined:nuh/ nin.

V-belt drive pulleys are selected so that the ratio of the diameter of the fan drive pulley to the diameter of the pulley on the motor shaft corresponds to the ratio of rotational speeds:

Din/ Duh= nuh/ nin

The ratio of the diameter of the driven pulley to the diameter of the drive pulley is called the gear ratio of the belt drive.

Example. Select pulleys for V-belt transmission of a fan with an impeller speed of 1780 rpm, driven by an electric motor with a power of 7.5 kW and a speed of 1440 rpm. Gear ratio transmission:

nuh/ nin=1440/1780=0,8

The required speed of the impeller will be provided by the following equipment: a pulley on a fan with a diameter of 180 mm , pulley on electric motor diameter 224 mm.

Schemes of V-belt transmission of the fan, increasing and decreasing the speed of the impeller: