Facades of high wooden private houses. Material requirements: what kind of wood are kitchens made of. D wooden facades

Facade decoration is an important component of the architecture of the building

Nowadays, building your own home is not just a tribute to fashion.

And the decoration and decoration of the facade is business card property owner. And the more diverse, complex and bizarre it is, the more memorable and bizarre it is. Facade finishing gives you the opportunity to express your feelings.

The right combination in the selection of facade materials at the design stage allows you to simulate the future space of the living environment.

We live in an age of more and more new and practical materials for exterior finish able to withstand all weather conditions and requiring minimal maintenance.

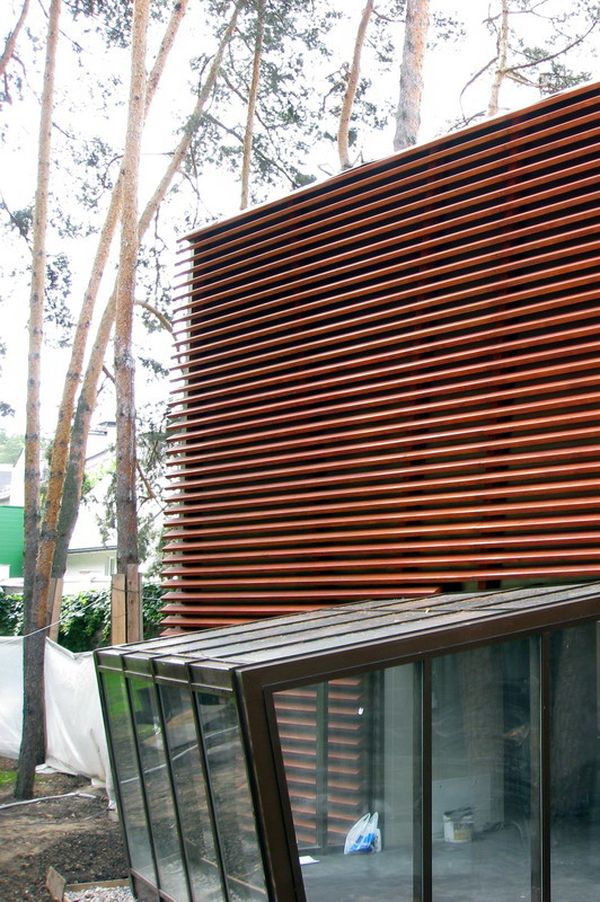

But until now, natural and environmentally friendly products are in great demand for finishing the facades of houses. clean materials including exotic woods. As part of our conversation, I would like to see natural wood in the first place. Exactly facade board made of wood can show us durability, reliability and visual comfort. Ventilated wooden facades are in great demand among the modern generation of architects and designers.

Despite the fact that the tree is a living natural material - facades from natural wood(oblique planken profile) are sufficiently resistant to external influences external environment. The facade board is resistant to cold, sun, wind, rain. Performance characteristics will not change for a long time, and the appearance will be impeccable.

The style of home decoration in a combination of wood, glass and stone is currently considered very modern and practical, emphasizing the status and financial success of the owner of the house.

The use of facade boards by various segments in combination with modern materials gives you the opportunity to make your home truly unique and original.

Hinged ventilated facade.

Harmonious wooden facades of houses- this is not a luxury and not a tribute to fashion on the part of the owners of buildings, rather, it is taking care of your family, including maintaining the health of loved ones and creating psychological comfort. Modern facade materials help to make real the most refined fantasies of building designers.

IN old times man used a tree to build housing, in our age the tree has returned again as construction material, but new technologies have literally breathed a second life into this facade finishing material. We can offer you a huge selection of tree species that are used in our climatic conditions for more than one year, and have proven themselves with better side in this matter. These are durability, resistance to external influences, environmental friendliness and aesthetic appearance.

Finishing the facade of the house and filing the roof with a wooden facade board on a frame system of guides to which the mounting plate with the board is attached allows it to move freely when the air humidity changes, creating an air flow between the building itself and the facade.

"Floating" fastening system, easy to assemble, does not require additional maintenance, if necessary, one or more elements of the facade can be replaced without completely replacing it. Finishing the facade of a country house with a tree has many advantages over other materials, and above all it concerns the preservation of the natural appearance of the building for a long time. Our facade system allows you to create wooden ventilated facades not only on new houses, but also for the restoration and restoration of rather old and not presentable houses. wood finish facades of cottages on a ventilated basis is quite resistant even to the most strong winds, high humidity and temperature fluctuations, this makes living in the house extremely comfortable and desirable.

Facades are like a dress for a fashionista. Hiding the "wrong side", they give the building a complete look.

To the most common facing materials natural origin carry the tree wood siding(planken), although this is an expensive pleasure for construction customers.

To the most common facing materials natural origin carry the tree wood siding(planken), although this is an expensive pleasure for construction customers.

Types of wooden facades

Of all kinds wooden facades planken stands out - siding. Planken is not just a facade board made of wood, akin to lining. The material is boards planed on four sides, the side ends of which can be beveled or rounded. A planken with an oblique profile is more in demand by designers, since it can be used to create both classic versions of wooden facades and modern style. However, products with rounded edges also look very interesting. Today, in private architecture, the planken is widely used to interior decoration buildings, to create ventilated facade systems (installation of ventilated facades ), construction of arbors and fences. Sometimes it is used as a deck board.

Ventilated wooden facade: materials

As with any material used for outdoor work, planken is presented with high requirements in terms of resistance to adverse weather conditions. And although sometimes made from pine, yet it is mainly made from Canadian red cedar, thermally modified abachi, larch. This is truly an elite, beautiful and durable material.

![]()

![]()

Benefits of finishing the facade with planken

Here it is appropriate to first recall how lining is done with clapboard. The most significant drawback in this case is the "thorn" connection, since such a cladding does not tolerate swelling or, on the contrary, drying out of wood that occurs during changes in humidity. Lining boards can warp, twist. If it becomes necessary to replace one of the boards, this will not be possible due to the peculiarities of the spike connection.

Unlike lining, planken lining is fixed so that there is a small gap between the boards, which provides ventilation and does not allow moisture to linger in the cracks. Wooden facades can absorb moisture and swell slightly during periods of high humidity, but the lining will not deform due to the ventilation gap.

Classes and price

Like many other lumber, planken is divided into classes depending on the quality of the products: "Extra" ( top quality), "A", "B", "C" - the last two refer to the economy class.

Products of any category retain the main advantages of the material - durability, strength, resistance to negative atmospheric influences. The main difference between products of different classes lies in their appearance: planken of the Economy category may have knots, small non-through cracks, resin pockets, which do not affect its performance in any way.

Products of "Extra" quality do not have these visual defects. The price of the material depends not only on the class, but also on the dimensions of the board. Wooden facades- it is stylish, reliable and durable.

Thermoash, thermopine: features, price, how to buy

Thermowood has become one of the most used wooden materials thanks to the combination of advantages natural wood and excellent performance. Thermopine or thermoash are free from such disadvantages as rottenness, high hygroscopicity, susceptibility to deformation or easy flammability. During production, these materials are heated with steam to a temperature of 180-220 degrees, which increases the density of wood, changes color and evens out the texture.

One of the most popular materials of this type is thermopine. Affordable price and good specifications allow you to use it to create an attractive external appearance of buildings. If you want to make your home resistant to various atmospheric factors, then you should buy thermopine because such facades are not afraid of rain, snow or wind. They withstand both severe frosts and extreme heat equally well. Buy a thermopine can different sizes and species, and its price will be quite affordable.

Another type of heat-treated wood is thermo-ash. The strength of this wood and its elasticity were noticed many centuries ago, and its beautiful texture was used in the manufacture of furniture and various decorative elements. In our time there was new material – thermoash, which retained all the qualities of natural wood, but at the same time came to new level operational characteristics.

Many people are now striving buy thermoash for finishing facades due to its high density and hardness. Exactly thermoash was the first wood to be heat treated. The result is a material that guarantees maximum wood stability and wear resistance. In order to protect your home from the influence of various weather factors, you can buy thermoash.

Facade systems of this material have excellent moisture resistance, strength and thermal conductivity. When choosing thermoash, price plays a role, since only high-quality products are able to ensure compliance with the declared characteristics. In addition, heat-treated ash is not inferior to exotic wood in its beauty. As you can see, for beautiful and environmentally friendly houses, it is the best suited thermoash, price which is quite affordable and corresponds to the quality.

An abundance of new forms, bright facing materials, a variety of customization options kitchen furniture turn pleasant moments of interior design into real agony of choice. For those who do not agree to exchange the warmth and luxury of natural wood for fashionable plastic and aluminum, manufacturers will offer wooden facades in hundreds of design options. The fee for naturalness is high, but there is an alternative - a combination of solid wood with other materials.

Natural wood, especially from valuable hard rock, is an expensive material. And when looking at the variety of offers of wooden facades in different price segments, doubts creep in: are all products really made of solid wood?

Wooden furniture: luxury and warmth

On the wooden surface visible relief

In fact, there are several options for the production of wooden facades. Headset doors can be made:

- From a bar - the most expensive material. Solid beams are spliced together using the "groove-spike" method. The connection is reinforced with an adhesive layer. Mostly hardwoods are used.

Solid wood doors with contrasting solid insert

- Furniture shield. More accessible than an array. Small pieces of wood are glued together into a single piece by pressing.

- Combined material: the frame of the paneled door is made of solid wood, and the insert (panel) is made of veneered chipboard, glass, glued board.

- Veneered facades: MDF or Chipboard boards, glued laminated timber from inexpensive softwood, facing - natural veneer.

The price of wooden facades for the kitchen directly depends on the cost of materials and the complexity of their processing. Spliced furniture boards They are cheaper because there is practically no waste left in their manufacture.

Only a master can determine the material of manufacture "by eye"

The most affordable are combined doors. The shade of the decorative layer of wood and the insert is selected so that it is impossible to visually distinguish the material from wood and slab.

Precious wood veneer sets can cost more than inexpensive solid wood furniture.

Natural wood kitchens: types of facades and production features

If earlier wooden facades were associated exclusively with classic kitchens in a traditional format (doors with panels, cornices and showcases in the upper tier), today among factory products there are furniture for modern laconic kitchens: with blind doors, bent shape, in unusual textures and shades.

Solid wood furniture in a loft interior

Pros and cons of wooden facades for the kitchen

Wood is an expensive and capricious material. Despite the complexity of processing and the need for special care, facades for the kitchen made of wood have undeniable advantages:

Gorgeous sets for country houses

- Durability. When choosing quality products from solid breeds, you can safely expect that several generations of the family will admire the furniture.

- Environmental friendliness. In processing, only harmless PVA glue is used; adhesive compositions based on synthetic resins are not used. Wooden facades cannot become a source of unhealthy fumes, even if a polyurethane-based varnish is used for the top coat.

- Uniqueness and wide choose color solutions.

wooden furniture after a few years, you can update by removing the top lacquer layer. One of the main advantages is the possibility of restoration and repair. Small chips, scratches, cracks are easily repaired at home, and after professional restoration traces of defects will not be detected even by a specialist.

Naturally, furniture facades made of wood are not without drawbacks. The kitchen is a room with the most unsuitable conditions for natural wood. Constant fluctuations in temperature, hot steam, high humidity- factors that must be taken into account when choosing facades.

Advantage: furniture can be restored several times

So that the furniture does not lose its attractiveness, install a powerful hood, give preference to an electric oven And hob without drying out the air. Monitor the humidity level - the indicator should be stable all year round.

The temperature in the room should not exceed 24 ° C. Headsets with tinted lacquered doors should be protected from too bright light from the window so that the surface does not burn out with spots.

Material requirements: what kind of wood are kitchens made of

Regardless of what breed kitchen furniture is made of, the material must be evenly dried. Be sure to check the humidity: wood should not contain more than 10% moisture.

Manufacturers use only proven raw materials

For custom-made parts for one headset, dried wood is not used different ways: The material may behave unpredictably in the future. Array Process protective equipment that penetrate deep into the fibers. Impregnation is completely invisible on finished goods, but perfectly protects furniture from moisture, fungus, insects.

Oak: refined texture and excellent performance

The most common hardwoods for kitchen fronts are beech, oak and ash. The lightest is beech. Almost white wood is easily tinted in any shade, and the pattern has a pronounced pink tone. Solid oak is valued for its interesting texture with a deep pattern. Often tinted in desaturated golden hues that emphasize the natural beauty of the wood.

Bright tone and beautiful texture: sweet cherry

Among the popular species is sweet cherry. The material is much softer than oak or beech, but this array is chosen by connoisseurs of rich natural patterns.

Ash detail in enamel and patina

Budget facades softwoods are made from cherry, birch, alder. The most affordable - from pine, spruce.

Doors made of inexpensive wood are tinted under an expensive breed

Soft woods are more prone to warping and cracking. Therefore, for kitchens it is better to choose hard rocks. Furniture from soft wood must be protected from shock.

Panel facades: solid doors made of finger-jointed timber

Fashionable wooden facades for kitchens in a modern style are solid. The main decoration is the natural pattern, texture and tone of wood. It is the absence of decor in the form of panels, carved overlays, cornices that gives elegance to such sets. Designers recommend hiding even outdoor fittings by equipping retractable and hinged doors touch sensors.

Solid blind doors without thread and panels

The material of manufacture may be different. The most expensive are facades made of spliced timber of expensive species: oak, walnut, beech. Exotic rare breeds are also used - rosewood, wenge. But the price of furniture can be simply sky-high.

Solid wood kitchen

Available facades - cherry, alder, cherry, wood conifers. Solid products made of glued boards are more durable. If deaf kitchen doors seem boring, there is an alternative: factory-made solid facades with a false panel. Finished doors are milled, creating a traditional "paneled" look. You can also order hand carved on shield products.

Paneled doors: manufacturing features

Wooden facades with panels are a classic that never goes out of style. The design of the door is assembled and glued separate parts:

Doors with classic and slatted infill

- Straight parts of the frame, milled on one side for an insert and decorated with a molding - a decorative rounded cut.

- An insert with a thin section around the perimeter that connects to the groove of the frame.

The parts are glued together. Finished facades are clamped onto special machines until dry.

The price of products depends on the material of the frame and insert. For the frame, it is desirable to choose solid wood.

Panel material:

- MDF - used in curved facades, because bending the shield to the desired shape is difficult and expensive.

- Wood lattice. Use rails of any breed: the element is not subject to stress.

- Insert from inexpensive soft wood.

- Glass or stained glass - often used in the manufacture of doors for the upper tier of furniture.

Doors with glass, grille, standard insert

The panel part is also made from expensive wood, but the price in this case increases. Available option: hardwood frame and inexpensive veneered plywood or MDF insert.

Luxurious carved facades: handmade or high-precision computer technology

The most expensive and difficult to manufacture are carved wooden facades. Until now, the workshops offer hand carving. Each detail of the pattern on the tree is cut and polished by hand. Such furniture is unique, and at the request of the customer, the craftsmen will transfer any pattern to the doors.

IN industrial scale manual decoration was replaced by the work of high-precision milling machines. The whole process - from drawing to the completion of the thread is controlled computer programs.

Thread types on kitchen fronts:

- Carving along the contour of the frame.

Geometric pattern on the contour

- Openwork carved inserts.

- Carving on solid facades.

3D wooden facades

A novelty in the furniture market is textured solid 3D facades. Such doors are made of solid wood or MDF boards. Body waves, honeycombs, asymmetric patterns are created by special milling machines.

Textured products are not veneered. Decor options - painting, tinting, varnishing. Facades with voluminous texture are ideal for modern urban interiors.

Finishing options: toning or painting

Classic options design of wooden facades - toning and varnishing. Impregnation of the facade with special dyes (usually alcohol-based) does not completely cover the surface. The composition is absorbed unevenly, emphasizing the natural pattern, giving the wood the necessary shade. After the tinting layer has dried, the products are varnished.

Apply water-based or polyurethane-based varnish. Water varnish is absolutely harmless, has no specific smell, dries quickly. But in the kitchen it is better to use classic varnish. The layer will protect the wood from water and stains. Lacquered surface requires care and careful handling: the layer is quickly covered with scratches, and when overheated and from exposure to some chemical substances may darken.

Finishing layer: gloss, enamel

Another processing method is impregnation with special oil. Oil penetrates inside the facade to a depth of 3 mm. The effect is a pronounced pattern, muted shine and a natural golden tint. The disadvantage is that the facade, covered with oil, cannot be repainted, varnished, or changed color. To get rid of the oil layer, you will have to grind the surface to the depth of impregnation.

Enamel painting - great option for kitchens from inexpensive breeds. There are technologies for creating a matte, glossy surface. Painted facades patinated, applying contrasting layers along the contours of the panels, frames.

Veneered facades: an alternative to expensive solid wood kitchens

Veneered facades from furniture manufacturers are an affordable replacement for expensive wood sets. Outwardly distinguish MDF board, trimmed with high-quality veneer, from the facade of a solid array is almost impossible. The difference is only visible on back side doors. If the base is used joiner's shield, then the transition between the veneered surface and the base is absolutely invisible.

Imitation of luxury: types of veneer for the kitchen

In the production of veneered facades, natural valuable hardwood veneer is used. The most common types are oak, maple, walnut. Products coated with exotic species are popular - zebrano, wenge, merbau.

exotic veneer: zebrano

Veneer is produced by peeling thin sheets of wood from a single bar. The strips are dried. Natural veneer is glued to the facade using cold glue and hot methods. In fact, veneer is a fairly durable layer of natural wood. Standard thickness of sheets used in furniture production- 3 mm.

But material from hard and exotic rocks is expensive. As an inexpensive alternative, the new kind veneer - fine-line. This is a natural imitation of valuable varieties of veneer. Raw materials for production are inexpensive soft breeds. Thin sheets are cut from a bar. Special knives peel off the webs different thickness.

The resulting sheets are dried. Paint the dried veneer in different shades, depending on the color and texture of the rock, the pattern of which they plan to recreate. The dyed stripes are collected in piles, combining several shades. Treated with glue and dye. The collected stacks are glued together under pressure. Subsequently, strips of veneer are cut from the glued stack, ready for facing.

Fine-line material

Veneered facades on stage finishing paint, tint, varnish.

Pros and cons of veneered kitchens

Main advantage kitchen set, covered with veneer - affordable price. Furniture will cost a little more than a set of fiberboard covered with plastic. Advantages of veneered facades:

- material stability. Veneered furniture doors do not crack with temperature changes, do not deform.

Wenge: veneer with a matte finish

- The surface can be repaired. The chipped areas are restored, the finish coating is restored.

- Perfect look. To the touch, veneer is indistinguishable from wood, but it is devoid of small defects that cannot be hidden in solid wood products: knots, small cracks, pattern heterogeneity.

- Flexibility. You can veneer both concave and curved panels. Radius doors are made of MDF, which easily takes the desired shape, then veneered.

- Naturalness and durability. At proper care a well-made veneered facade can last for decades.

Solid MDF fronts with veneer

The disadvantage of veneer is the need for careful cleaning. Only special non-aggressive compounds intended for the care of wood and varnish should be used for washing facades. Weak spots doors covered with veneer - edge edges.

Design: luxury kitchens with wooden and veneered facades

IN spacious kitchens country houses look luxurious classic kitchens with wooden facades covered with matte enamel with contrasting patina. Designers offer to combine several shades in one tier.

Single-tier furniture with solid wood facades

Connoisseurs of traditional solutions will love the kitchen with white fronts and lattice inserts in the upper tier cabinets.

Doors with bars and curved facades upper tier with glass

The lower and upper parts can be tinted in different shades: more light tone- for wall cabinets, solid matte gray - for the lower ones.

![]()

Natural wood has natural beauty. Even without carved details, golden patina and carvings, wooden cabinet doors look expensive and elegant.

Tinted details in matte lacquer

IN modern kitchens instead of carving, complex painting and openwork, designers play with a non-standard shape. Multi-level headsets made of solid wood in combination with a bright gloss of metal - A New Look on the traditional cuisine.

Curved doors and irregular shape

Even a tiny kitchen will be decorated with wood and high-quality veneer. To focus on the texture of wood, choose a contrasting shade of the walls and soft warm lighting.

natural veneer: designer furniture

Details from inexpensive breeds are tinted in dark colors. Headset in Japanese style from soft rocks with a wenge tint - the choice for a city apartment.

original solution: dark tinted and frosted glass

Experiment! Combine facades made of solid wood, veneered boards with other materials. Dilute dull glossy veneered facades of the lower tier with snow-white acrylic gloss.

lower tier– veneer, top – acrylic

When choosing facades made of wood or veneer, do not try to save on quality. Give preference to factory parts. You will be sure that the doors will not “lead” in a couple of months, cracks will not appear on them, and the varnish will remain transparent and shiny.

Video instruction for the manufacture of a facade made of natural wood

The video shows step by step how to make furniture facade from natural wood milling table using an Enkor cutter:

Wooden facades are always beautiful and unusual! Wooden facades of houses from SITISTROY LLC are also practical! Indeed, such designs can make any building truly attractive, highlight it against the general background and draw attention to it.

What do we offer?

LLC "SITISTROY" offers to install wooden facades and find out how profitable it is! We offer you a variety of prices and appearance options:

- from larch planken;

- from planken pine;

- from thermowood planken.

planken facades have a number of features with which our masters are well acquainted. Installation is carried out year-round, and the buildings on which installation is carried out can be not only residential, commercial or office, but also industrial.

Planken material is unusual. Using it, a skilled craftsman can create whole images on the walls. This will help different color shades, for which only environmentally friendly paints are used.

Advantages of wooden facades:

- they perform not only aesthetic, but also protective functions, covering the walls and taking on all the adverse effects from the outside;

- they are not afraid of the effects of high and low temperatures, as well as their differences;

- their installation can be carried out even on old buildings after their repair;

- after installation, even the most dilapidated building will look like new;

- thanks to wooden facades, problems with heat and sound insulation can be solved.

Mounting Features

Installation of wooden facades includes several stages. First of all, a frame made of steel or aluminum is installed on the outer walls. Holding preparatory work not required in this case. Mounted on top of the frame wooden facade . Thus, between it and the wall there will be a gap through which air will circulate freely. This will dry inner space if moisture gets in and prevents condensation from forming.

Wooden facades can be insulated. For this purpose, our craftsmen use a heater, the installation of which is carried out in such a way that there is also a gap between it and the base. The latter allows you to dry the insulation if moisture gets on it. In turn, this allows you to extend its life.