Drawings of elements of the kitchen corner cabinet. Do-it-yourself sink cabinet - an interesting option

When choosing such an intuitive and simple piece of furniture, it is important to pay attention to details, because a kitchen sink cabinet can also become an additional storage place for various small items, stylish element decor. Let us consider in more detail the selection criteria, taking into account the size of the kitchen, the type of models and the durability of materials. Or maybe it’s worth making an original sink with your own hands and decorating it for the interior?

modern furniture It has various forms and dimensions, it is made of expensive and economy class materials. In order not to get confused in a wide range, we will try to determine the main parameters that you need to pay attention to when buying.

Multiple bowl option

Differences in form and type of structures

Depending on the place allotted in the environment, you can choose the desired configuration of the locker.

There are three types of structures:

- Straight - a classic rectangular or square bedside table, which is easy to build in anywhere on the work surface, except for the corners, or take it to a separate "island". Depending on the size, you can think of several shelves for storing dishes, drawers, and build in a washing machine.

Roomy straight

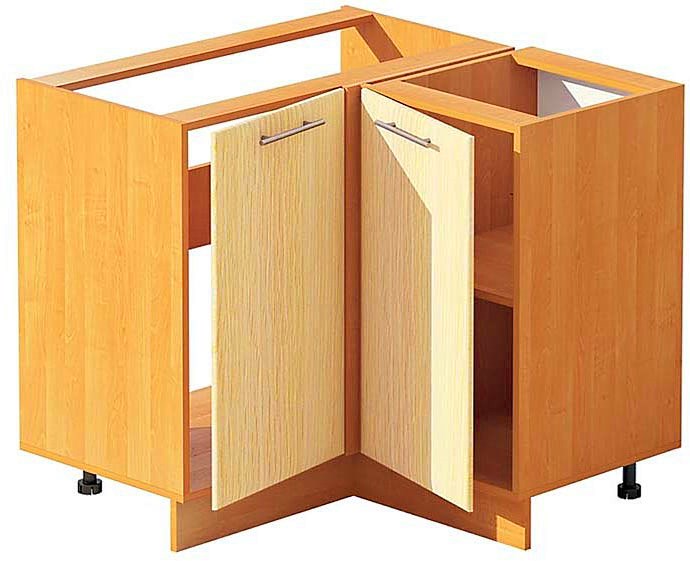

- Corner - cabinet, which is adjacent to two perpendicular walls of the room. Can have a rectangular, L-shaped or triangular shape, takes up little space, suitable for small spaces. But such designs have a significant drawback - in order to comfortably use them inner space, will have to equip the furniture additional devices – drawers, brackets or carousels.

Rational use of space

- Trapezoidal - roomy model with one or more doors, compartments, wide table top. Allows you to build a sink of any shape, place inside a lot of shelves with dishes.

multifaceted

As for the shape of the shells themselves, it all depends on personal preferences. There are models of square, round, oval, rectangular and asymmetric shapes. Models in the form of a wide rectangle are considered the most capacious; they can wash both a large pot and a baking sheet.

Rectangular bowls are the most spacious

Many housewives prefer sinks with several compartments (double, triple), where one bowl is used for washing dishes, the second - for defrosting food or fruits / vegetables. The number of compartments can vary from 1 to 5. Convenient with a special mesh or ribbed surface designed for drying.

On a note! For added convenience the sink can be equipped with grates, a basket, cutting board, colander. Models are designed for spacious kitchens- in small room they take up a lot of work surface space. One of the most functional "bonuses" is a food waste chopper.

The optimal size of the kitchen sink

To determine the dimensions, it is important to consider not only the presence free space but the size of the kitchen itself. For medium and small rooms, small straight lines or corner models. Massive trapezoidal or rectangular with a wide table top is best installed in big room.

Kitchen island

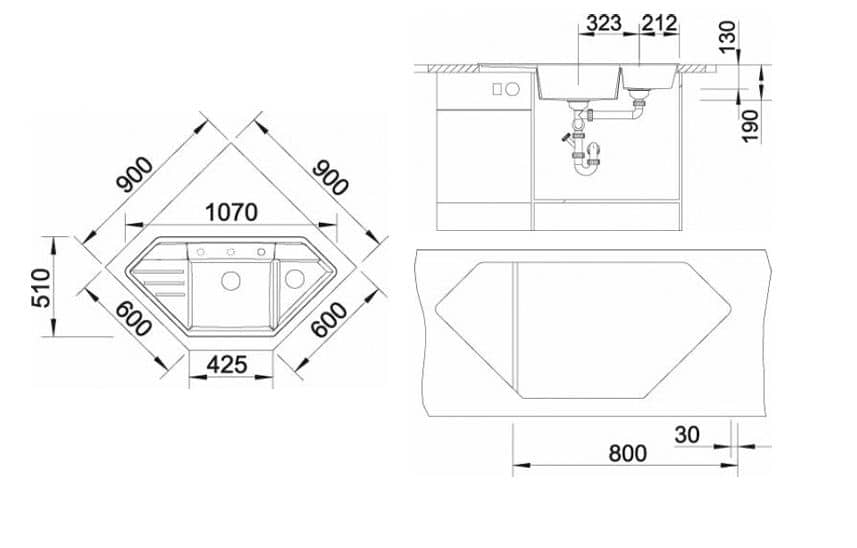

On a note! A standard straight bedside table has a width of 50 cm, a depth of 60 cm, but models with a width of at least 80 cm are considered the most comfortable. The most common sizes corner design– 90*90 cm.

An important size parameter for a sink is its depth. If you wash dishes in a shallow bowl, splashes will scatter on the walls and adjacent cabinets, and too deep washing is corny inconvenient - you have to constantly bend over. Models with a depth ranging from 16 to 20 cm are considered optimal.

Important! The size of the sink should be such that from it to the wall and the edge of the countertop there is a gap of at least 5 cm, and the distance to the stove is 50 cm or more.

Cabinet installation methods

Depending on the configuration and material of the furniture, the sink can be installed in three ways. Each of them has its own operational features.

- Overhead - classic version for a straight nightstand with a collapsible top. The “roof” is removed from the furniture, the place of which is occupied by the sink and fixed by the edges. This option is most suitable for self-assembly- even a beginner will not have any difficulties with installation and connection to communications.

Sink cover option

- Mortise - a hole is made in the countertop of the cabinet, where the sink is lowered. To increase the tightness of the joints, use rubber compressor, and the seam is additionally treated with a special two-component adhesive. Such a model can be installed independently on wooden countertops(MDF, solid wood, chipboard), but for surfaces made of artificial stone, it is worth calling a specialist.

Mortise for wooden kitchen

- Integrated - form one unit with the tabletop due to the careful fit and snug fit. For self-assembly, such bowls are not suitable - to achieve monolithic surface, without having the necessary skills and materials, it is extremely difficult. Therefore, they are made to order along with the countertop.

Integrated artificial stone model

Integrated sinks are most often made of natural or artificial stone. This is the most expensive construction, but also the most practical - the absence of sides and high-quality polished joints exclude the penetration of water and small debris, guarantee ease of use, long term furniture service.

On a note! Monolithic ones differ in installation cost. Most simple models literally hold on to one glue - with a heavy load or from the operation of the grinder, gaps may form at the joints. Professional installation assumes an exact match.

The integrated model looks like a continuation of the countertop

Materials for sinks and cabinets

Cabinets are made from the same materials as kitchen sets. The most popular materials: chipboard, MDF and solid wood. Price is the deciding factor for many.

- chipboard - the most a budget option with a huge range color solutions. Disadvantage: the threat of formaldehyde resin fumes in case of poor-quality edge processing or damage to the protective layer of chipboard. The main thing is that in production it is used moisture resistant plate. The best coverage– laminate high pressure HPL.

Chipboard or MDF coatings can imitate almost any material

- MDF - can be called the "golden mean" between price and quality. This is a wood chip board. binder in which they serve exclusively natural materials: lignin and paraffin. In structure, it is denser than chipboard, holds fasteners better and does not evaporate harmful substances. The best option would also be a coating with HPL plastic - it is the most scratch resistant, has a wide variety of colors and fits snugly to the surface without letting moisture through.

- An array is expensive, it can swell or dry out from hot air. It looks spectacular due to the unique structure of the tree, but requires constant care. Undeniable advantages are the reliability of fastenings and the possibility of restoring damaged surfaces.

The countertop can also be made from solid wood.

If you can quickly decide on the choice of material, then you usually have to think about buying a sink. Let's take a closer look at the three most popular options for modern interiors.

Stainless steel sinks

Stainless steel is a classic material known for its durability, strength and hygiene. You can choose an economy model, and a premium class - it all depends on the thickness of the sheet and the quality of the seams. When choosing a stainless model, give preference to welded - made using the technology of "invisible seams", so that it lasts longer. As for the type of coating, the most practical is matte or “anti-graphic”: drops and scratches are not so noticeable on it as on a mirror gloss.

The original bowl of stainless steel

Disadvantages:

- The instability of the coating to scratches, after which corrosion spots may form.

- A monotonous design that does not differ in a variety of colors.

- Loud noise of water hitting metal (may be compensated with sound-absorbing padding or thickness).

Sound-absorbing pad will significantly reduce the noise effect of stainless steel

Stainless steels made of AISI 18/10 steel are considered to be of the highest quality - in this grade of metal, the chromium content must be at least 18%, and nickel - 10%. Optimal Thickness steel - at least 0.9 mm (or better - 1-1.5 mm). On the market you can often find offers of economy class sinks. Before agreeing to a tempting purchase, ask the seller for a certificate or passport for the product. If the ASTI 202 brand is indicated in it, this is the designation of technical steel, which is easily corroded and quickly fails. If everything is in order with the metal, check its thickness - cheap products with an indicator of 0.4-0.6 mm can be deformed from heavy dishes.

Advice! When buying a stainless steel sink, take a magnet with you: if it sticks, the protective layer is too thin, and rust will form on the metal over time. It is optimal when the magnet slides over the surface or does not react to it.

Ceramic sinks - pros and cons

Cabinet with a ceramic sink looks stylish, especially if you place it near the window - reflections sun rays on a glossy surface will give the interior bright accent. make modern models from porcelain or faience (porcelain is considered more durable, but also costs twice as much).

In addition to the spectacular appearance This material has other advantages:

- Does not require special care– perfectly cleaned with detergents and warm water.

- Resistant to high temperatures.

- Eco-friendly.

- It is distinguished by low noise (ceramics is able to absorb sounds, so the noise of the water jet will be almost imperceptible, unlike a table with a stainless steel sink).

- Holds heavy dishes with ease.

- The color does not fade or wash out.

- It can have a different texture, decor and non-standard shape.

Ceramics can be the highlight of the kitchen

This model is quite heavy, so the nightstand must be designed to support an impressive weight. Snow-white faience ceramics may darken over time, and stains from bright dyes may form on colored faience (porcelain is better protected from these shortcomings). The most significant minus of a ceramic bowl is fragility. Worth not holding back cast iron pan- and cracks or chips may form on the surface of the sink. And a plate or glass that slips out of your hand is almost guaranteed not to withstand a fall on ceramic surface.

Sinks made of artificial stone

Liquid stone or acrylic - the most affordable option. Such sinks are made to order along with the countertop, but there are more economical options- overhead, mortise models. Produce liquid stone from mineral chips and acrylic resins, resulting in a surface that is strong, light and with a pleasant roughness.

Mortise model made of artificial stone

Disadvantages:

- May crack or dent from boiling water, a hot pot or pan.

- Changes color from food, chemical dyes.

- From abrasive detergents and hard washcloths leave noticeable scratches.

- Dark color may fade in the sun.

Worthy of special attention innovative materials, such as tectonite or agglomerate. In their composition, about 80-90% is occupied by stone chips(quartz, marble, granite) with the addition of fiberglass and polyester resins. They withstand temperatures up to 300 degrees, are not afraid of scratches, do not lose color after exposure to ultraviolet radiation and detergents, and reliably imitate the structure natural stone. Manufacturers additionally treat surfaces with an antibacterial and dirt-repellent coating. The only drawback is the high price.

Integrated bowl made of quartz agglomerate

Note! Connoisseurs of natural stone can purchase a container made of marble, onyx or granite, but they are expensive, because they are hollowed out of the rock and need regular processing protective compounds. This is an exclusive item that will only be appropriate in luxurious interior, whose owners spend little time cooking. By performance characteristics sinks made of agglomerate will give odds even to granite.

A model made of natural stone will become a luxurious element of decor

Making a cabinet with your own hands

Despite the huge selection of furniture, it is not always possible to buy what is needed for the kitchen. custom size. In this case, there are two options: draw up a sketch, take measurements and entrust the manufacture to a master furniture maker, or take on the job yourself.

The easiest way self-manufacturing- alteration of one of the direct elements of the kitchen set. To do this, you need to disassemble the locker, cut it out on back wall holes for communications, and cut a hole to fit the sink. You can go further and make a nightstand from MDF, chipboard or wood from scratch.

Model from an old cabinet

On a note! For home experiments, it is better to take MDF or moisture-resistant plywood with a thickness of at least 12 mm. DS boards are easy to cut, but in artisanal conditions it is difficult to edge them with high quality in order to prevent formaldehyde evaporation.

In addition to the base materials, you will need:

- Surface mounted or mortise (for self-assembly best option- stainless steel).

- Furniture screws.

- Electric jigsaw or a wood saw.

- Sandpaper.

- Antifungal primer for wood.

- Accessories: door hinges, handles, internal corners.

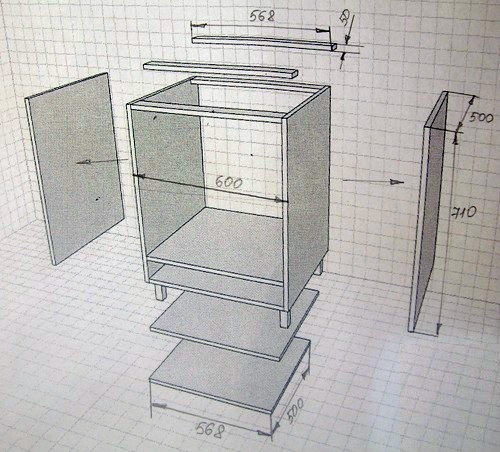

Before you go to the store for building materials, you need to draw a sketch of the future product on paper. You will have to rely in the calculations on your own measurements and the availability free space.

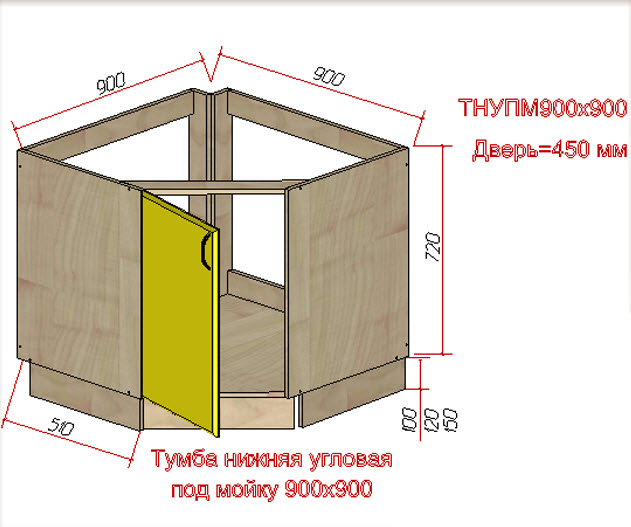

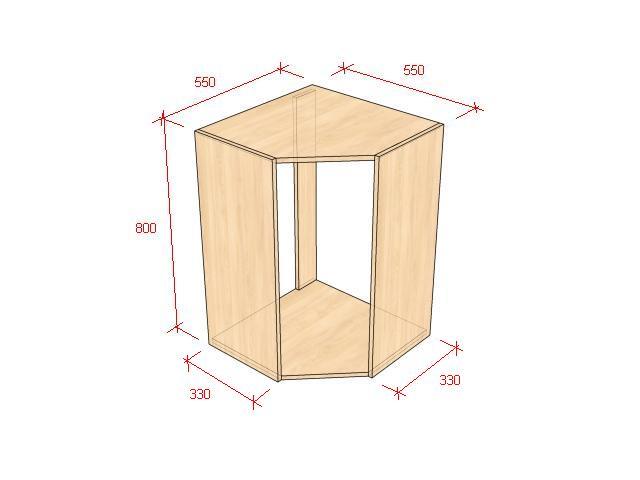

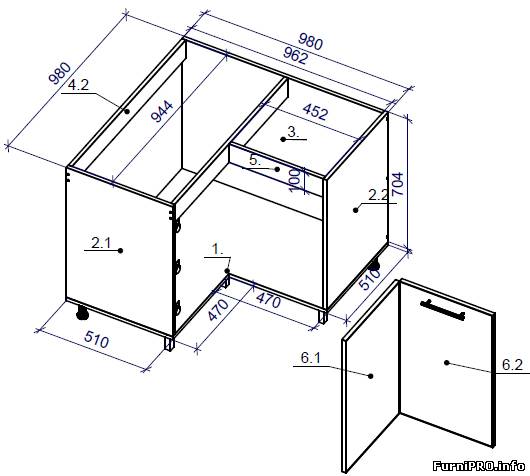

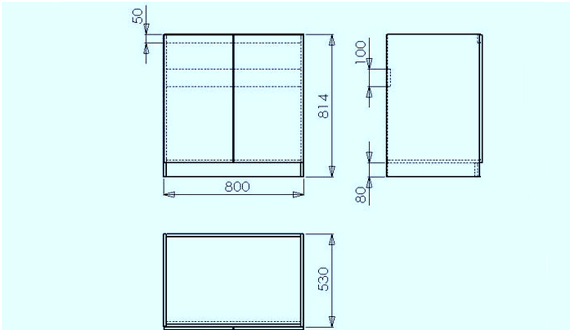

Corner cabinet - the most popular solution for small rooms, but in order to construct it with your own hands, you will need an accurate calculation and a detailed drawing, for example this:

Scheme for manufacturing corner bedside tables

Advice! In order not to be mistaken in details, use special programs (for example, Basis-Mebelshchik, PRO100 or AutoCAD), with which you can not only calculate the amount necessary materials and components, but also to create a visual projection of the future product.

Work algorithm:

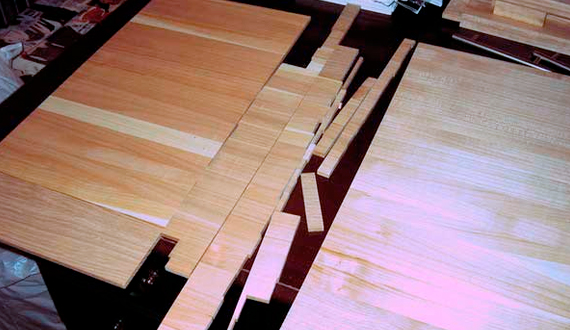

- According to the drawn up drawing, blanks are cut out of plywood or chipboard under the walls, bottom and doors. If you are planning a countertop sink, you will not need a countertop - you just need to choose a sink of the appropriate size. If it is large enough, it is better to equip it with a mortise model, and add the countertop area to the blanks.

Assembly diagram

- Wooden fragments are sanded and treated with a primer.

- After drying, they assemble the box for the cabinet using internal corners and self-tapping screws.

- On the back wall or bottom, cuts are made for pipes, and in the table lid - a hole for the bowl.

Hole cut along the contour

- Doors and handles are hung on the front.

- A container is lowered into the slot and sealed with silicone.

- It is recommended to treat the finished cabinet with any waterproof coating - varnish, paint, PVC film. After that, the structure is fixed on the wall with dowels, and the sink is connected to communications.

In a homemade cabinet, you can install simple internal shelves

Modeling for an overhead sink in AutoCAD

Two ways to install a stainless steel bowl:

Cutting into the table top:

You can assemble a cabinet for a kitchen sink with your own hands, but it will take a lot of time and effort. It is easier to entrust the manufacture of furniture experienced craftsmen, who will do everything for your interior, help you install and connect to the pipeline correctly.

Kitchen important element home improvement space. It carries an important functional load. It is here that food is prepared, the process of harvesting, conservation takes place. Most often, it also has a dining area for daily meals. Therefore, a reasonably planned space greatly optimizes all processes. This is especially true for small kitchens. Furniture kitchen set the main building block of this system. Rationally distribute workspace a corner cabinet for a sink for the kitchen, which will be discussed later, will help.

Design features

Before considering the main types of corner kitchen cabinets let's decide for what purposes the corner segment serves and what functions it performs.

The meaning and functional loads of the corner cabinet under the sink:

- connecting - that is, thanks to this segment, a transition occurs furniture set from one wall to another;

- technical - one of the important nodes is located in it, namely the sink and communications to it. This main purpose - rationalizes the used area. Corner sink is convenient because it can be equidistant from the desktop and hob. This makes food preparation much more convenient. In addition, it can accommodate sinks of various configurations and sizes. Inside it, in addition to the communications drain system, there may be water filters, a flow heater, a garbage container, drawer systems for storage, most often household chemicals;

- aesthetic function - this element fits organically into the common space.

Varieties

There are two types of corner sink for the kitchen: L-shaped with an acute angle, these sections are also called attached, and a cabinet for the kitchen with a beveled corner. They differ in internal overall dimensions, device, quantity and method of opening the doors, ease of use.

Corner cabinet for the kitchen under the sink, the main overall dimensions.

In kitchens made according to individual orders may be slightly different overall dimensions.

L shaped

Beveled corners

Choice of size and shape

In order to make the right choice of corner cabinets, you need to know their features, advantages and disadvantages. In attached sections with an acute angle, the internal space is smaller than that of pedestals of the second type. They can be equipped with two doors or one that opens two sections at once (accordion door). The convenience of the second option is that access to the far corner inside the section is simplified. The corner cabinet for the kitchen under the sink with a beveled corner is more spacious, as it has a larger volume. It is possible to install a sink bigger size. In addition, they are convenient in terms of use, as the beveled corner makes it easier to access the sink. The disadvantages include the fact that she has only one small door.

The problematic place of the corner sections under the sink is the countertop. The standard canvas has a size of 60 cm wide. In the case when postforming, a laminated tabletop is used, a seam falls on the corner segments. This point is not relevant for cast countertops made of artificial stone. Corner overhead sinks are sold that fully correspond to the dimensions of the working surface of the cabinet. Or for this section, purchase a special postforming 120 cm wide.

What else you need to consider when deciding on the choice of the corner segment:

- kitchen area. The bevelled section takes up more space;

- you should immediately decide on the size and shape of the sink for the kitchen.

You can not immediately purchase it, but you need to select a model and download a technical drawing on the Internet. When you buy a cabinet, take it with you and show the sales consultant a drawing. This will help to avoid possible errors;

- material used to make kitchen and countertops. Remember that laminated board is most prone to swelling from moisture. Therefore, it is desirable that the surface of the countertop be seamless;

- general style and interior design;

- decide whether the corner element will contain additional elements: grinder, filters, flowing heater. In this case, it is reasonable to give preference to a segment with a beveled corner.

Only by summing up all these points, you can decide on the choice.

Manufacturing materials

When deciding on a cabinet, you need to be guided by the materials from which it is made. Main types of materials:

- laminated board - an affordable option. This is, in fact, pressed glued wood chips covered with a layer of plastic. It should be noted that moisture should not get inside the plate. For these purposes, the ends, in the part where water can get in, are protected by an edge;

- pedestals made of laminated board with MDF facades. MDF is wood waste crushed to a dispersed state, vacuum pressed under high pressure. the top plate is covered either thin layer special film, or veneer (thin cut of wood), veneered facades. The slab can be protected by staining. Painted MDF has a wide color scheme. Their advantage is also that they can be embossed. The facade does not require trimming the ends with an edge. The most popular and optimal, in terms of price-quality ratio, option;

- natural wood - in the vast majority of cases, only facades are made from it. The tree, though the most environmentally friendly pure material, but also quite capricious. It must be well dried, expertly fitted and covered with special varnishes. These compounds protect it from moisture, temperature changes, mechanical stress;

- facades made of plastic and glass - they are quite beautiful and expressive. But expensive, like wood. They are framed in aluminum end tape. Susceptible to scratches, glass, to chips and cracks;

- cabinets made of food grade metals. It is most often furniture for food production where high sanitary and hygienic requirements are imposed.

Washing plays an important role in ease of use.

Wooden

Options for corner segments

There is a wide range of sinks on the market, including corner sinks.

What types can be used:

- corner sinks - sinks are suitable for cabinets with an acute angle rectangular shape. For the second type, with a beveled corner, the choice is wider, since more working surface;

- round sinks 50, 60 cm, these are standard sizes. It should be remembered that a section with an acute internal angle is also suitable for sink 50;

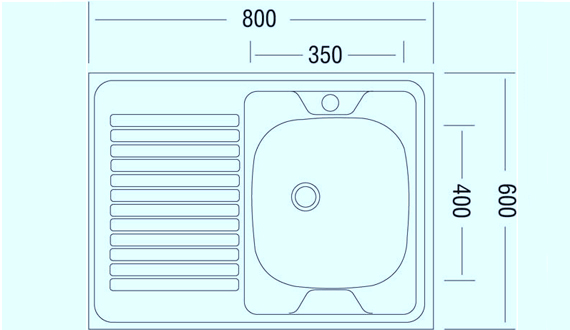

- direct washing - most often manufacturers produce them in lengths of 60 cm (600 mm) and 80 cm (800 mm). The depth depends on the type of sink (consignment note or mortise) and shape.

Floor corner cabinet under the sink, its choice is directly related to the size and shape of the sink.

oval

Rectangular

Filling

Do not forget to take into account the interior filling of the cabinet. If technical units (chopper, water filter, flow heater) are concentrated there, then it is reasonable to use a pedestal with a beveled corner, as it is more spacious. When you plan to use it for storage, then both options will do. You just need to decide on the dimensions of the stored things. This will determine the height of the shelves.

In the attachment segment with an acute angle, it is possible to use special retractable baskets, swivel shelves, which is quite convenient.

If a garbage container is located in the corner segment, then when planning the internal space, it is better to know its size in advance. Then you can rationally accommodate additional shelves.

![]()

Deciding what the corner will be floor element under the sink, consider the combination of the above factors. best material countertop fake diamond. Then a sink made of the same material is more suitable. If the work surface is covered with a laminated board top, then it is more correct to use overhead sinks.

A segment made entirely of laminated board is not much cheaper than a pedestal with MDF facade. Therefore, from an aesthetic and practical point of view, the second option should be preferred.

The main thing, for the safety of the cabinet - maximum protection prevent water from entering the plate. To do this, all possible joints are sealed with a sealant, the edges in contact with moisture are trimmed with a protective tape, and a furniture plinth is installed.

How to make your own

If you have certain skills, you can independently assemble the corner segment. A laminated plate is the best option for a do-it-yourself kitchen, from which it is easiest to make it.

The sequence of actions is as follows:

- determine the type of section. To do this, consider the size of the room, and what will be located inside the segment;

- check out the main types of sinks for corner cabinets. Both types are suitable for sink 50. Choose the best option and download the sink drawing;

- think over and sketch a drawing of a cabinet with detailed dimensions;

- with a drawing, contact a company that cuts laminated boards to size. They will also tell you where to purchase accessories and end tape;

- when all the blanks are available, you can assemble the corner segment. To begin with, the sidewalls are mounted, they are attached to the bottom of the cabinet. Next, install and secure the connecting strips. Then the legs are screwed on. Mark and cut recesses for door fasteners. Install them, hang the doors. Depending on the type of sink, overhead or mortise, prepare the countertop in order to mount the sink. In order to make a hole in the countertop, use a jigsaw. Pre-make markings on the countertop in the form of a sink. The mortise sink is installed only on the sealant. It is important to follow the assembly sequence.

So, the floor corner segment for the sink is an important element of the kitchen furniture set. It carries a significant functional load. There are two main types of pedestals. Depending on a number of the above facts, one of them is chosen. A significant element is the shape and dimensions of the sink, internal filling. When choosing a material, interior design plays a major role.

Video

A photo

lower tier kitchen furniture usually consists of a chain of cabinets connected together and covered with a common table top. When making a kitchen set, there is a reserve for savings, which Igor Kalinin talks about.

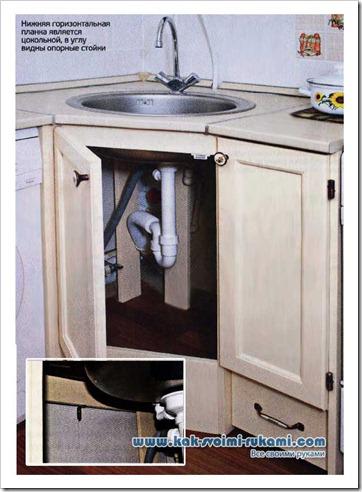

IN small kitchens it is convenient to place a cabinet with a sink in the corner, especially since the water supply and drain are located there. The single door of this cabinet, as a rule, stands at an angle of 135 degrees to other doors. Make this corner cabinet more difficult than any other, and more material will be needed. But the problems are not limited to this; during installation, you will have to make numerous cutouts for communications in the sidewalls and the bottom shelf of the cabinet.

The lower tier of the kitchen with imitation corner cabinets

Racks inside the corner "pedestal".

Connection of pedestals adjacent to the corner with horizontal planks using corners.

You can refuse cabinets in the kitchen

I decided to do it easier - not to make such a time-consuming and material-consuming piece of furniture, but to limit myself to just its imitation. Of course, there is a work surface with a mortise sink and a mixer, a facade with a handle and a plinth, too. Not only the cabinet itself!

First, it is necessary to install adjacent cabinets strictly according to the level. Then connect them with horizontal crossbars - bar 1 on top (see figure) and the same bar at the bottom (ego plinth plank, and it is not visible in the figure). I secured the planks with the help of "corners, bent to the desired angle. If there are full-fledged cabinets on both sides of the corner imitation, then connecting them with planks is not difficult. Another thing is if there is a place for washing machine that stands on the floor. Then the sidewalls of its niche, also imitating a cabinet, must be attached to the wall with corners.

The lower horizontal bar is a basement, support posts are visible in the corner

The frame will be more rigid if the horizontal strips are attached to the wall.

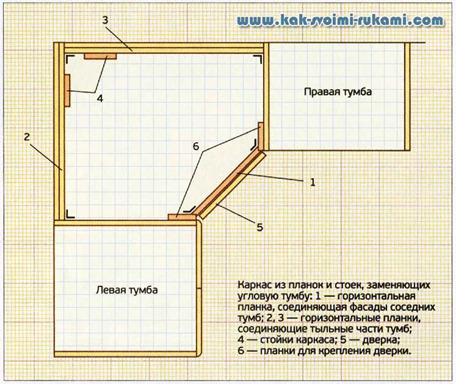

Cabinet frame manufacturing

The next stage is the connection of the pedestals with horizontal strips 2 and 3 adjacent to the wall (see figure) using corners. In the corner, these horizontal strips are fastened together and with racks. Racks are bars of furniture board. They are located in places where there are no communications. Planks are attached to them with self-tapping screws.

The upper edges of the sidewalls of all pedestals and the planks connecting them lie in the same horizontal plane. A tabletop will lie on them, which I will attach with corners or self-tapping screws through upper shelves full cabinets. The joints of the tabletop parts are located on the racks and connected with special ties. They are sealed with silicone and covered with decorative overlays on top.

Inside the imitation cabinet there is free access to communications. And yes, there is plenty of storage space.

It is better to drown the lower bar-plinth. This looks more beautiful, and it will become more convenient to use the sink: the feet do not rest against the base.

Homemade corner cabinet - drawing

A frame made of planks and racks that replace the corner pedestal: 1 - a horizontal bar connecting the facades of neighboring pedestals; 2,3 - horizontal strips connecting the rear parts of the pedestals; 4 - frame racks; 5 - door; b - straps for fastening the door.

Below are other entries on the topic "How to do it yourself - to the householder!"

The sink is the most demanded element of kitchen furniture. Cabinet under the sink, like others kitchen items It's easy to make your own. In order to make a beautiful and creative cabinet for washing with your own hands, you need a little skill, the availability of the necessary materials and the right tool.

Preparatory stage

The cabinet for washing is one of the simplest in its design; its manufacture will be accessible even to a novice master. At the same time, all such objects are similar in design to each other. The only exception is the internal contents - the location of the shelves and so on.

From the materials you need to prepare:

- two side walls;

- two upper struts;

- doors - one or two, depending on the design and width of the bedside table;

- bottom plinth;

- wooden pins and furniture screws;

- furniture hinges.

The most acceptable material that can be used for the production of kitchen cabinets is chipboard or MDF, as well as boards for plinth and spacers. The following tools will be required:

- screwdriver;

- drill;

- manual a circular saw for cutting chipboard and boards.

When making a sink with your own hands, its dimensions will depend on the dimensions of the sink, which is mounted in the cabinet, as well as the size of the room where this furniture will stand. You can make a wide bedside table in which the sink will be combined with the countertop.

How to make a cabinet under the sink? The most common option is a cabinet with a width of 400 to 800 mm. Double models can be up to 1.2 meters wide, if the dimensions of the kitchen allow. Standard sizes sidewalls remain the same regardless of the width and are 530x814 mm, where 814 mm is the height, and 530 mm is the bottom depth.

The width of the bottom is formed on the basis that the dimensions of the thickness of the chipboard, from which it is planned to manufacture the sidewalls, will be subtracted from the total width of the pedestal twice. For example, if the total width is 800 mm, as in the figure below, then the width of the bottom, provided that the chipboard has a thickness of 14 mm, will be calculated as follows: 800-14-14=772 mm. The spacers and bottom plinth have a length equal to the width of the bottom. The width of the doors is selected based on the width of the cabinet, but the height is a constant value. The width of the doors will have to be calculated very accurately and accurately. If a mistake is made in the calculations, the doors will either not close, or an ugly wide gap will appear between them.

Below are the drawings of the main parts:

Door calculation

The width of the bottom plinth, according to the drawing, is 80 mm. If we subtract 80 mm from the total height (814 mm), we get 734 mm. From this figure, subtract the thickness of the countertop for the sink (25 mm) together with the thickness of the edge multiplied by 2. If we take this dimension equal to 2 mm, we get 734-25-2-2=705 mm as a result.

- if the total width is 800 mm, divide it in half and get 400 mm;

- from this size, the width of the ends on both sides, equal to approximately 2 mm, is subtracted - it turns out 396 mm;

- the gaps between the doors, 2 mm each, and between them and neighboring furniture, also 2 mm each, are also subtracted - as a result, we have a width of 396-2-2 \u003d 392 mm. In order not to miss exactly, you can subtract another 2 mm, as a result we get the width of each door 390 mm.

Assembly

So in in general terms it is known how the do-it-yourself cabinet for the kitchen sink is calculated. This stage, along with cutting chipboard and boards, is the most important. It can be advised to cut not at home, but in a workshop with the appropriate equipment. But to collect better at home from prepared parts.

Before assembling the bedside table, it is advisable to coat the ends and places where the chipboard will be joined with silicone using a special gun. This will prevent the destruction of the material from moisture, which will inevitably fall from the washbasin. Do-it-yourself cabinet for washing is assembled in the following sequence:

- The bottom of the bedside table is connected to its sides. The bottom is located above the upper border of the plinth, the width of which, according to the drawing, is 80 mm. The bottom and side walls must be strictly at an angle of 90 degrees relative to each other. After docking through the sidewalls, two holes are drilled into the end of the bottom for furniture screws. They need to be drilled at a distance of at least 5 cm from the edge of the boards.

- In the same way, a bar, which is a lower plinth, is attached to the structure with screws.

- Next, two spacer bars are installed. One - on the facade, under the very top, flush with the upper ends of the sidewalls. The second is behind, somewhere 20 cm lower. Also fastened with self-tapping screws.

- Facades of doors under hinges are milled. For this, a special pen drill or cutter with a diameter of 35 mm is used. Recesses are drilled at a distance of 2.5 cm from the end of the door and at a distance of 10 cm from the top and bottom. The cutter deepens so that the loop fits freely there, but you can’t overdo it. Next, 2 hinges are screwed on each door.

- In conclusion, the reciprocal parts of the loops are screwed to the sidewalls. It remains only to insert the sink into the assembled body of the nightstand.

How to install a sink

This step is relatively easy to perform. The metal shell is inserted into the body from above, but it must be fixed, otherwise the required rigidity will not work. If this is not done, the cabinet will fall apart sooner or later (see video).

There are two methods for attaching a metal shell to the body.

- The same silicone is used, and two tasks are solved at once - sealing the upper part of the body at the junction with the sink, the whole structure is given rigidity. To do this, silicone is applied around the entire perimeter to the upper end of the case. After that, a sink is put on top. Assembled in this way, the case can be immediately installed, connected to the drain and used.

- Self-tapping screws are used to fasten the sink - this option is more reliable. Please note: in any of both methods, silicone is applied to the upper end of the pedestal - primarily for sealing, and not just for fixing it.

Below are the dimensions of the sink, under which the cabinet was built. It will be installed in the structure without problems. There are options for the location of the sink both on the right and on the left, when viewed from the side of the facade.

As a result, the made piece of furniture will look something like this:

Other manufacturing options

The bedside table with a sink has many versions and is installed in different places kitchen or bathroom, depending on the layout and area of \u200b\u200bthe premises. One of the options is a wide bedside table, in the top tabletop of which you need to make a cutout for installing the sink (see the picture below).

Can be crafted corner sink- this approach saves space, the design fits organically into the interior. It turns out a little more complicated, but the basic assembly principles remain the same. There are also various options installation of shelves in the interior of the cabinet. For finishing facades and sidewalls, a variety of methods are used - such as lamination with paper-resin films, pasting polymer films, staining with waterproof paints and others. Choose your option that suits your interior and the size of the kitchen.