How to make a coffee table. Making your own wooden coffee table from available materials

A coffee table is always a flight of fancy. There are practically no restrictions on how a coffee table should look like, what design, shape, height, dimensions it should have. This greatly facilitates the task, the main thing is that this piece of furniture harmoniously fits into overall design premises. Nevertheless, many people want the coffee table to be an original, exclusive, unique element of the interior. To do this, it is not necessary to look for finished products in stores for a long time, you can muster up the courage and make a table with your own hands. Many questions may arise: how to make a coffee table yourself, what materials to use, what shape to choose and others, in this article we will present several instructions for making coffee tables without spending a lot of effort, energy and finances.

The most popular materials for coffee tables are considered to be wood and glass. Of course, there are plastic tables, and metal ones, and with stone elements, but still the classics and charm of natural wood tip the scales to the side wooden products. Glass coffee tables look advantageous in hi-tech or other rooms that involve the use of interior items in light colors. That is why we will consider only glass and wooden models tables. Height coffee table depends on the interior in which he will have to fit in. For example, coffee tables with a height of 25 - 30 cm to 50 cm will look advantageous with low sofas and armchairs. If the furniture around has standard sizes, then the table should be of such a height that it is convenient to use it - so that you do not have to bend too low or stretch high while sitting on the sofa. standard height coffee table - 50 - 65 cm. Tables with a height of more than 70 cm are considered high and are not suitable for all interiors, only where they will be used while standing. In the examples below, there will be tables from the first two categories, as well as one model that can be made of any height, including more than 70 cm.

The easiest coffee table to make can rightfully be called a table made of wooden boxes. Such a table can be made from old or new ready-made wine boxes, but if they are not available, and there is no opportunity to purchase either, then it can be made from wooden slats or plywood. For example, suitable wooden planks 7 to 20 cm wide and 15 to 20 mm thick. If you want to make plywood, then keep in mind that it must be sanded, 30 cm wide and 60 cm long. In addition wooden materials you will need self-tapping screws, mounting angles, furniture wheels, stain and varnish.

Option 1. Coffee table from ready-made boxes.

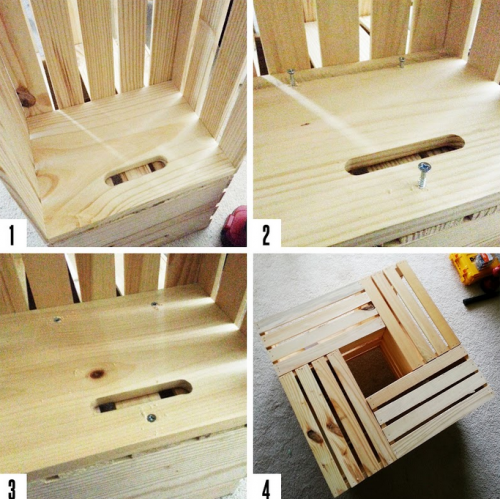

Ready-made wine boxes are good because they greatly facilitate the task, in fact, it is enough to install them correctly, fasten them together and put them on wheels:

- The first step is to make a frame for the table. It will create additional support and increase the strength of the structure. It will also be possible to attach wheels to the frame so that the table can be moved around the room. For the manufacture of the frame, you will need a bar or board 40x100 mm. Since the shape of the coffee table will be square, the frame should be 4 beams knocked together into a square, and a 5 beam should be fixed in the middle, as shown in the figure.

- The dimensions of the frame must exactly match the external dimensions of the future table. Cut two long boards and two short boards. We lay long boards parallel to each other, insert short boards between them, resting their ends against the transverse boards. You should get an even figure. Then we grease the ends of the short boards with glue, press them to the long boards. Then, from the inside of the resulting square, we fasten the boards together with the help of corners and self-tapping screws or screws. We also glue the fifth board inside the square and fix it with self-tapping screws.

- We put the boxes in the design of the future table. We connect them together with self-tapping screws. The side walls of the boxes must be screwed to the rails of the bottom of the adjacent box. There should be at least two fasteners for the side wall - one at the top and the other at the bottom.

- We install the boxes on the frame and fasten to it with self-tapping screws.

- We attach furniture wheels of a suitable size to the frame.

- We are preparing a mixture for painting the table, if we want to make it darker. If a light coffee table is also suitable, then it is enough to open it with varnish. After painting, the surface of the table must be sanded, including from the inside.

- We open the coffee table with varnish and leave to dry. The number of layers of varnish depends on what effect we want to achieve. The more layers, the more glossy surface and the less visible the structure of the wood.

Instead of varnish, you can use satin polyurethane, then the surface of the wood will be satin.

Option 2. Coffee table "boxes" made of plywood.

Such a table can be made completely from beginning to end, spending money only on the purchase of 2 sheets of sanded plywood, self-tapping screws, wood glue or PVA glue. For greater durability and similarity with real wooden boxes plywood thickness should be 15 - 20 mm. For such a coffee table, the price will be lower than for a table made of wooden boards. So let's get started:

- First, we cut narrow plywood side walls boxes, they must be deaf. For 4 boxes there should be 8 walls 400 mm high and 300 mm wide. The cut must be even, so it is better to use a jigsaw.

- We grind the edges of the side walls of the boxes, remove the burrs.

- Since the wide side walls of the boxes and their bottom are planks that are located with gaps, the next step is to make sections or planks for the walls of the boxes. We cut the plywood into strips 100 mm wide and 600 mm long. The gaps between the planks have a purely decorative function, so if you have chosen other sizes for the drawers, then calculate the location of the sections and optimal distance between them (5 - 10 mm).

- For each long side wall of a drawer 300 mm wide, 3 sections 95 mm wide and 600 mm long are needed. If you do not plan to make gaps, then you can use strips 100 mm wide. In total, 24 such slats are needed for 4 drawers.

- For the bottom section of each box 400 mm wide, 4 sections 95 - 100 mm wide and 600 mm long are required. For 4 drawers you need 12 bottom bars.

- On all slats, on the narrow side, we drill two holes with a diameter of 4 mm for fastening to the side walls.

- The next step is to assemble the boxes. We coat the ends of the side plywood walls with wood glue or PVA glue. Then we attach the strips to them, screwing them with self-tapping screws. The heads of the self-tapping screws are sunk into the wood so that they can be hidden with a finish.

- Each box should have the following dimensions: height 300 mm, width 400 mm, length 600 mm. Having installed these boxes in a figure, as in the photo, we get an extravagant table. We connect the boxes with each other with self-tapping screws, pulling the side narrow walls with the walls of the adjacent box.

- To make the design even more durable, we manufacture for it square frame from a wooden bar or board, as described in the previous version.

- The free space in the middle, between the drawers, can be left as it is, or can be made less deep. To do this, a piece is cut out of plywood that repeats the dimensions of the hole, then the piece is inserted into free space and is fixed at about half the height of the box. Now it will be possible to fill up some decorative material on top or put a vase.

- We cover all hats from self-tapping screws with furniture mastic or putty. Then we grind the surface of the boxes.

- We open plywood with varnish (alkyd or polyurethane) in several layers.

The coffee table is ready. Please note that for slats you can use more than thin plywood, for example, 6 - 10 mm thick. The product will turn out not too strong, but more reminiscent of boxes.

DIY carved wooden coffee table

This manual is useful for those who have in their arsenal lathe, milling, grinder, clamps and other tools. From the materials you will need a wooden beam 50x50 mm and wooden boards 25 mm thick, and a width of 45 mm to 10 - 15 cm, wood glue Titebond-2.

Making a table leg

Since we decided to make the coffee table round, we only need one leg. For its manufacture, we take a beam of 50x50 mm and glue it along each other. To do this, you will need Titebond-2 wood glue and clamps or clamps. Please note that you should not use one beam for the legs required thickness, the product will be more durable if you glue two beams of smaller thickness into one.

- The coffee table leg will have carved form, reminiscent of balusters for stairs. We give the glued workpiece the necessary profile on a lathe.

- We grind the surface of the legs for the table.

- We cut out the eyes in the legs to secure the supports - the side legs. It is best to make eyelets in the square part of the leg, one on each side. The depth of the eyelets is about 1 cm.

- Side legs are cut only from solid board of the required width and thickness, gluing is not allowed, and there should be no knots and cracks. We cut out 4 blanks and carefully grind. The edges are milled with a semicircular cutter.

- The side legs should fit snugly into the eyelets of the main vertical leg. If the shape is chosen correctly, then there will be no need to cut spikes on the side legs, the entire side leg will be a spike.

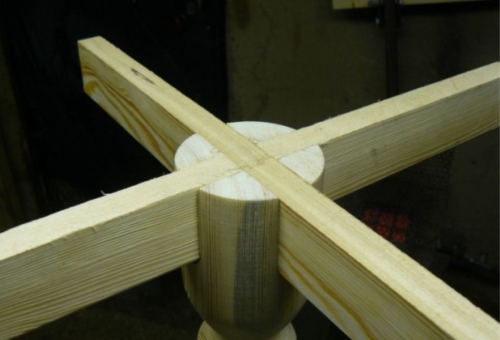

- In the upper part of the riser - the vertical leg, we select through holes for the cross with a cutter.

- We make a cross from boards 45 mm wide, 19 mm thick, the length depends on the size of the countertop. The ends of the cross should rest against the future underframe.

- We glue the cross into the hole in the upper part of the vertical leg.

The leg is almost ready, so let's move on to the underframe.

Making the underframe and fixing it to the leg

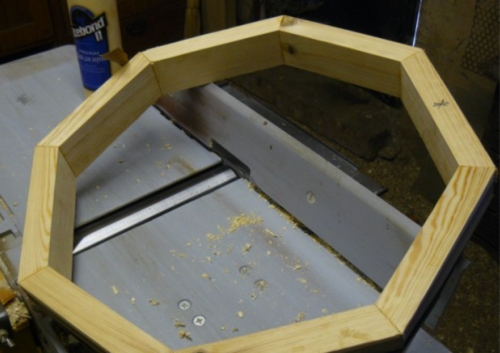

For a round coffee table, a hexagonal base is perfect. For its manufacture we will use wooden boards 20 mm thick and 45 mm wide.

- We cut the blanks so that they form a strong hexagon.

- We carefully grind the surface and glue the workpieces together.

- To make a decorative edging of the underframe, we glue wooden planks with rounded edges along the outline of the underframe.

- We fix the underframe to the crosspiece using self-tapping screws 65 mm long.

Making a round tabletop

The next step is a round tabletop. For its manufacture you will need a furniture shield. In this case, the tabletop was glued together from two furniture boards 300 mm wide. The most difficult thing is to cut an even circle. To do this, it is necessary to determine the center of the future tabletop, fix the nail in it, and put something like a compass on the nail. For example, a piece of plywood of the required length will do. During cutting, the cutter rests against the edge of the plywood, and the circle is even.

The round table top for the coffee table is carefully polished and the edge is processed with a milling cutter.

Coffee table assembly and surface treatment

Do not mount the tabletop directly to the underframe. In the process of temperature deformation, it can crack along the seam. Therefore, so-called crackers are used for fixing. First, we make crackers, as shown in the photo. Then, in the crosspiece, we cut out holes for them with a cutter.

We install the table top on the underframe and the leg with the cross. For convenience, we turn the structure over and align the arrangement of the elements. Then we insert the crackers into the holes in the crosspiece and fasten the crackers to the countertop with self-tapping screws.

![]()

The coffee table is ready - it remains only to open it with varnish. To do this, the surface of the entire product is polished again, then stain is applied, after it dries, it is polished again, since it is necessary to remove the raised pile. Now you can open with varnish. After the varnish has dried normal conditions table can be used.

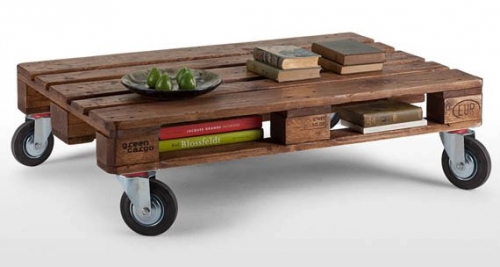

Do-it-yourself coffee tables from wooden euro pallets

Wooden coffee tables come in a variety of configurations and sizes. And recently, tables made of pallets have been especially popular. The cost of materials is minimal, and the final result depends only on the imagination of the one who makes the table. In this case, the whole secret is in the decoration. The choice of color, pattern, decor completely changes the look of the table. And there is a hidden advantage in this - it is enough to update the finish of the coffee table from the pallet, and it already looks like new design interior.

So, first of all, the wooden pallet must be carefully sanded, removing burrs. Then open with varnish or paint in solid color(white, green, blue). Please note that the pallet must be painted all over: both above and below, and where it seems to you that no one sees. You can also draw a picture.

After processing, it is only necessary to attach furniture wheels of the appropriate size to the pallet. 4 wheels are fixed in the corners of the pallet with screws.

![]()

Further decor of the coffee table from the pallet depends on the wishes and imagination of the owner. Inside the pallet, you can lay out books in beautiful catchy covers or albums. If you want to pour pebbles or other decorative stones, then the pallet needs to be finalized. To do this, even before fixing the furniture wheels from the bottom of the pallet, it is necessary to fix a sheet of plywood, exactly to the size of the pallet. It will also have to be painted or varnished so that it does not stand out from the general background.

Now our pallet has a bottom, so you can fall asleep inside decorative materials, which will be visible through the slots in the top cover - the tabletop of the pallet.

For those who love glass coffee tables, the design can be further developed by placing a glass top on top of a wooden pallet and securing it with Velcro / suction cups or with special nails. On such a table it is no longer scary to put a cup of coffee without a tray, a vase of flowers and it is easier to take care of it. Even if something accidentally spills, the glass is easy to clean and wipe off.

The next simple version of a coffee table that combines wood and glass elements is a log table. It is unlikely that you will be able to buy a log in regular store, so you have to go to the sawmill and choose a suitable block. Pay attention that the wood is not affected by bugs or mold. It is advisable to cut the log to the required height there, at the sawmill, since it is difficult to do this at home.

After buying a block of wood, its surface is polished, and then it is completely covered with varnish, stain or oil. Sometimes the chumps are painted a dark bronze color or another shade that suits the interior design.

After the varnish or paint has dried, a round glass top using special suction cups or nails. The resulting coffee table will resemble a mushroom with a transparent hat.

DIY glass coffee table

As you probably already noticed, the glass elements in coffee tables are mostly countertops. Legs can be made from any suitable material - wood, metal, plastic. For example, you can buy ready-made metal legs in a furniture fittings store, order a countertop of the required size, and assemble a glass coffee table at home.

Fastening the legs and glass top is usually done using special suction cups or nails. And even the model wooden table on one curly leg, the manufacturing instructions for which are described above, may well have a glass tabletop, not a wooden one.

To make the product look beautiful, it will be necessary to sand the cross and the underframe, and also to fix the tabletop not with crackers, but with glass bolts or metal corners. It is also possible to fix the glass tabletop on a transparent adhesive, the excess of which must be carefully removed.

Keep in mind that a glass top is heavier than wood, so it needs to be supported by a sturdy base and leg. Also, the design of the coffee table itself can be such that the glass will be firmly held on it without additional fastening. For example, if a niche is provided under the glass in which it fits.

Do-it-yourself coffee table - easy to make yourself using improvised materials or buying accessories in a furniture store. The work is dust-free and takes no more than 2 days. To make a wooden coffee table with carved legs is possible only with the help of special turning carpentry equipment.

The desire to make home furniture with your own hands (for example, do it yourself Coffee table ik) is not always associated with a lack of funds for its purchase or with the lack of suitable copies in stores and furniture stores in the city. Some craftsmen boldly take up carpentry tools to make a coffee table with their own hands, because:

- the process itself gives them pleasure;

- making furniture for them is a hobby;

- work with unusual materials makes it possible to obtain unexpected results.

The choice of material for creating a coffee table

Before you start making a coffee table, a photo of which you will not be ashamed to post online or show to friends, you should pay special attention to the choice suitable materials. To create a coffee table is most often used quality wood and its derivatives. Such materials include:

- glued panels;

- solid array;

- beam;

- plywood.

In order to avoid annoying mistakes in the process of creating a high-quality wooden table, when working with materials, one should take into account the specifics of their processing. It is also extremely important to draw up correct, well-thought-out drawings.

Any of the above materials has both advantages and disadvantages. You need to know about them in advance. For example, plywood, although it is considered quite reliable and durable material, has an unattractive texture.

Chipboard properties

Chipboard is quite inexpensive, its edges are easy to process at home, and modern laminate allows you to imitate any variety of valuable wood species. However, chipboard does not tolerate moisture well. When water gets on non-laminated areas, chipboard begins to swell, losing its presentation. In addition, the glue used in the production of laminated boards, when dried, gives off harmful fumes that are dangerous to people.

Features of solid wood

A solid array is devoid of the shortcomings that are inherent in plywood and chipboard, but it is quite expensive. In addition, valuable wood species are difficult to process. At home, processing such material is unsafe for health, since you can get injured using a specialized tool. This is especially true for some types of redwood. Yew berry, for example, is generally poisonous. Another disadvantage of a solid array is that when it dries, it can crack or curl. It ruins it a lot. appearance, and the reliability of the wooden table drops sharply.

Choosing the ideal material

When viewing photos of do-it-yourself coffee tables, it becomes clear that they are best suited for creating them. wooden countertops and wooden planks or bars for legs. In this case, the tree "does not lead", it does not crack when dried, its strength is higher than that of other types of wood. The advantage of using wood is also its environmental friendliness and the price that is quite affordable for most.

We make a small coffee table with our own hands

Coffee tables made of wood have, as a rule, a typical, standard design. They consist of various legs and tabletops. The shape of the legs and table top, as well as the way they are attached, in various variations may differ greatly. It all depends on the skills of the home master in carpentry and, of course, imagination.

Preparatory work

Before you start processing the material purchased for the coffee table, you should decide what shape the countertops will be. As a rule, tables are made with a rectangular or oval top, since it is this form that is more convenient to use. But no one bothers to do something non-standard, interesting. With the help of a ruler or special carpentry patterns, the contours of the future tabletop are drawn on the workpiece, and then electric jigsaw tabletops of the desired shape are cut.

Working with a tabletop

In order to eliminate the appearance of chips, it is worth taking files for a clean cut of the laminate. If the tabletop is made of solid wood or glued wood board, then it is better to process the edge with a milling cutter. This technique will give it a beautiful relief. After that, the edge should be processed with fine sandpaper, and the coffee table top surface can be coated furniture varnish or stain.

If a chipboard was purchased, then after cutting out the countertop, it is enough to process its edges grinder. This will even out the unevenness. After that, using a building hair dryer, a decorative edge tape is glued.

Choice of coffee table legs

Before deciding on the choice of legs for the future coffee table, you can see photos and drawings of finished tables. At the same time, you can see that the legs today are made of different materials. For example, you can even use driftwood, or glued together planks of a round, square or other shape. These legs are attached to the table top with:

- glue;

- self-tapping screws;

- special corners.

If there is no time or desire to make legs for a coffee table using your drawings, then you can buy ready-made legs made of metal. You can find them in furniture stores and specialized stores that sell accessories. Before screwing the metal legs to the countertop, it is necessary to make holes with a drill in the places where they will be attached. In this case, the diameter of the drill should be two times smaller than the diameter of the self-tapping screws used. When the legs are installed, the finished coffee table can be installed in the place intended for it. After that, you can make drawings and projects for the manufacture of new furniture.

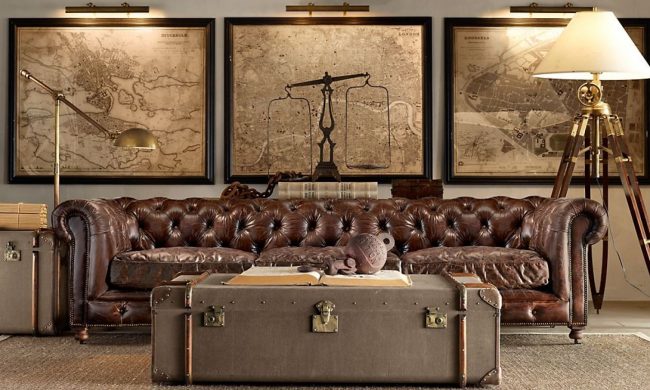

Creating the interior of your home, you want to fill it with comfort. Looking through offers furniture stores, you can easily find suitable furnishings. But the price of stylish things sometimes "bites". Buying the first piece of furniture that comes along just because it is needed is not worth it. Then it’s better to do such a functional thing with your own hands.

stylish things sometimes require minimal costs

A coffee table built from improvised means will look original. The owner will be able to create a model that will most organically fit into the interior. No one else will have a similar thing, as it is unique. There will also be an extra reason to show off your skills to the guests. Moreover, there are a lot of ideas for creativity.

handmade coffee table

Marine theme

Resting on the sea, many bring original shells, beautiful pebbles, starfish from there as a keepsake. And all this splendor is gathering dust somewhere on a shelf. Taking souvenirs as a basis, you can use them to create an original table for your home in maritime theme.

It is not difficult to build a piece of furniture in the romantic style - just follow the step-by-step instructions.

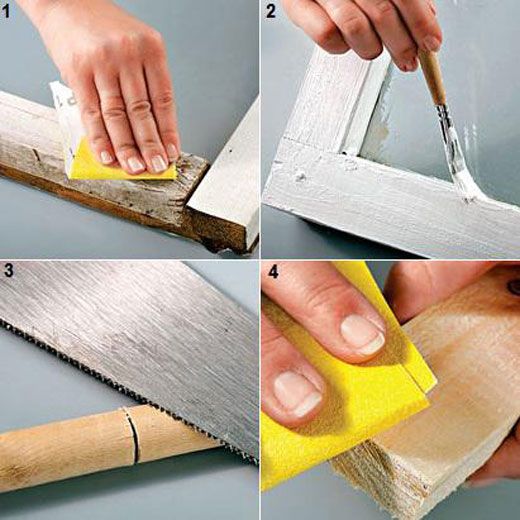

Having replaced old windows with plastic, you should not throw away wooden frames - they make excellent countertops. Cleaning the frame from dust, dirt and old paint, the surface is treated with emery, then the metal mounting corners are removed. If the glass is defective, it should be replaced with a new one.

this coffee table can be made by hand

The prepared frame is painted either acrylic paint or enamel. The first option is preferable if there is a desire to age the thing a little. Concerning colors, then it is better to put the first layer white, the second - blue. As it dries, it is lightly passed over with sandpaper so that whiteness shows through the blue. This motif is more combined with the marine theme. But you can do without blue paint - White color also goes well with the style.

idea realization process

The legs can be made from a shovel handle by sawing it into 4 equal parts. The approximate height of the coffee table should be about 34-35 cm. Roughness is removed from the surface with the same sandpaper.

You will also need boards about 8 cm long, commensurate with the width of the frame itself. You can take a furniture board and cut required dimensions. Legs will then be attached to these bars, so the joints need to be cleaned.

very handy glass top

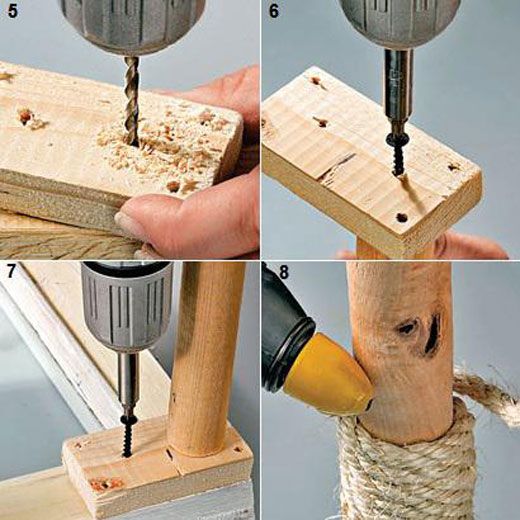

In the prepared bars with a drill, holes are made for fasteners. Through one of them, the legs are screwed to each plank with a self-tapping screw. Then this structure is fixed from the underside of the frame at the corners, fixing with self-tapping screws in several places. Each leg should be wrapped with a thin coarse twine, fixing the turns with building glue.

After all these actions, you get a table with a small recess. Sea souvenirs and shells, which have become decorative ornament. It is better to place them in random order. If necessary, some elements can be varnished or painted in a different color. For reliability, marine gifts are attached to the glass with a transparent two-component adhesive.

you can form a composition of shells

Glass laid on top of the table will complete the design. Its thickness must be at least 4 mm. Other parameters are set 1.5 cm less than the frame itself. When ordering such glass in the workshop, you need to ask for holes for fastenings to be made in it.

The tabletop should be screwed to the frame carefully so that it does not crack, having previously placed leather gaskets under the washers. A coarse rope is glued around the perimeter of the glass on the frame, not forgetting to tie it in the central place of the table knot. outer side frames are sometimes decorated with the remaining small elements of gifts from the sea.

under the glass you can put any decor and even plants

Suitcase variation

Perhaps the grandmothers had an old bulky suitcase lying around on the mezzanine. This can also be a good preparation for a stylish coffee table for those who love travel.

Legs for it can be bought ready-made, made of wood or metal.

elegant suitcase table

If a mobile option is provided, then they should be with wheels. To make it convenient to fix the legs on the bottom, a sheet of plywood is placed inside the suitcase, which is subsequently covered with felt, securing it with hot glue.

for avid travelers

Then it remains only to decorate the resulting table at your discretion (for example, pasting it with stamps or customs tags). Models of legs will help to stylize the suitcase under the existing interior. And if this thing itself is quite massive, then you can do without legs.

graceful legs

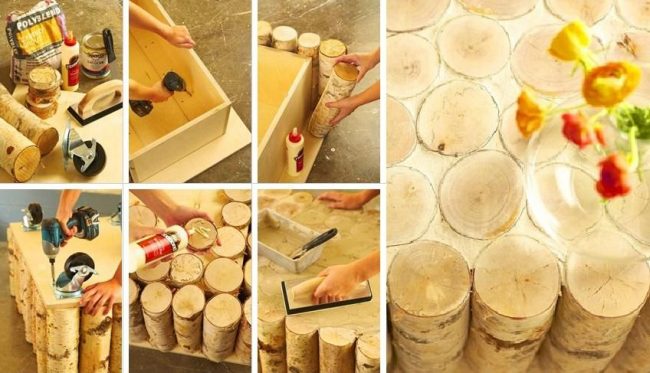

Ideas for country houses

Will bring to the countryside atmosphere warm comfort a table made from small logs. Birch beams will look beautiful, which will need 32 pieces. the same diameter and length. As a basis, you can take a wooden box, covered with a sheet of plywood of large sizes.

The protruding edges of the plywood sheet will become the place where the bars will be attached (along the perimeter of the box, commensurate in height with the length of the logs). To get an imitation that the table consists entirely of birch bars, on horizontal surface the boxes are laid out and fixed with adhesive dies.

The voids between them are filled with putty, which is then overwritten. From the bottom of the resulting table, furniture wheels are fixed at the corners, and the original mobile design is ready.

neat timber construction

You can choose other ideas for designs in a natural theme.

For example, logs can be easily replaced with branches formed around a black-painted plywood box.

Branches laid horizontally look quite original.

natural themes are very relevant

The construction of a solid block of thick wood looks great. The height of the legs varies at the request of the owner.

Such options can be listed indefinitely, but every craftsman will surely come up with a couple of interesting ideas himself.

hemp and saw cuts are very in demand in a modern interior

Other improvised means

People with creative thinking will always find variations of what improvised means can be used to make an original coffee table. Each model will look unusual if the work was done carefully and with love.

how to create a coffee table from improvised means

They began to throw away construction pallets less and less, finding a place for them in the interior. Pallets can be combined at your discretion, stacking in 1 or several tiers, fixing legs or wheels or not.

functional pallet structures

![]()

Boxes stacked sideways on a plywood sheet look great. This makes it possible to get not only a countertop, but also niches for storing things (magazines, books, knitting). The hollow center of the table is decorated with a flower pot.

do not rush to throw away wooden boxes

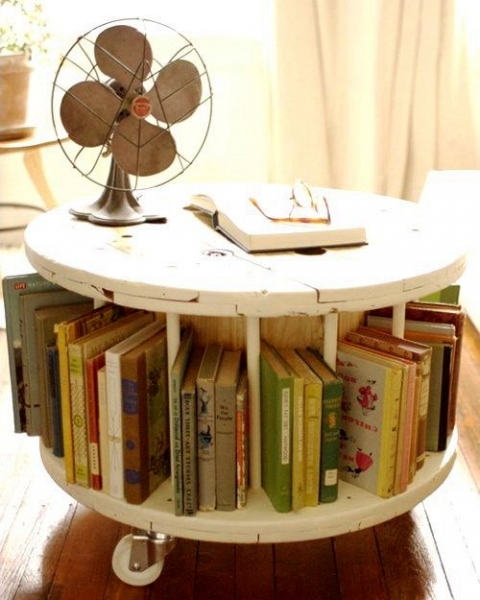

Those who deal with electricity professionally can borrow a wooden coil of the right size (from under the cable) at work. Having cleaned, processed and varnished the surfaces, they get a massive, but rather original table.

even cable spools are suitable

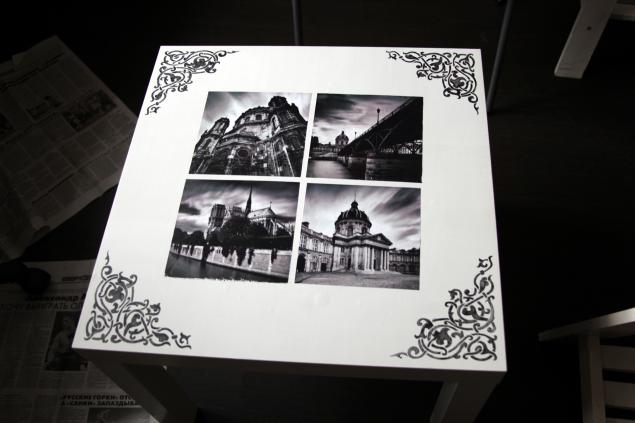

All wooden construction, before combining, should be put in order. Ready-made tables can be painted, stitched, opened with a stain and decorated antique. Sometimes decoupage is used, which will give the model an unusual look.

decoupage allows you to transform the surface

![]()

As you can see from the above, there are many opportunities for creativity. And here you can use not only household items, but also take into service the reserves of your professional activity.

take a look around - perhaps something can be used for a coffee table

So, for example, drivers can stock up on old tires, having issued them in the future with a rough tow line. Do not be shy about ideas that come to mind. It is better to strive to find opportunities for their implementation.

tire decor for avid car enthusiasts

In the era of electronic media, few bother to read printed publications. Despite this, coffee tables still occupy a place of honor in every home.

In addition to their direct purpose, they can be used for other useful things: serving a light breakfast or dinner, minor repairs and home creativity.

Simplicity of construction, a variety of shapes and designs, a minimum of tools - all these advantages of coffee tables attract the attention of home craftsmen. In our article, we will detailed overview popular homemade and give practical advice for their manufacture.

Design options for coffee tables

The easiest way to make a coffee table with your own hands, using shields from edged boards, veneered chipboard or MDF.

In order to hide the connection points of the plates, use classical method- assembly on round wooden spikes (dowels). All that is required from the home master in this case is to accurately mark the installation locations of the spikes on the ends of the sidewalls and drill mounting holes for them in the bottom and top cover.

The simplest coffee table made of MDF board

The simplest coffee table made of MDF board

To increase the rigidity of the structure between its side walls, you need to install a vertical cross member. A small niche for storing magazines and other little things will not be superfluous here. It can be made from a plate left after cutting the covers and sidewalls.

Mobility is a useful option of the table. It is implemented by installing furniture wheels on the bottom. Compact transport wheels can be hidden, or you can buy larger ones and deliberately highlight them. So we get an original table on wheels from polished bars supporting a massive wooden table top.

Those for whom mobility does not play a big role and want to see a solid table in their house in rustic style, you can offer a variant of powerful boards. Such a table will undoubtedly become one of the main decorations in the living room of any country house.

Reasonable laziness, combined with a thirst for creativity, often leads to interesting discoveries. One of them is a table old tire.

It's very easy to assemble:

- AT chipboard cut out two circles with a diameter of 3-4 cm less outer dimension tires.

- Four metal legs are screwed to the first circle.

- The bottom and the cover are fixed with self-tapping screws to the sides of the wheel.

- The jute rope is used to decorate the sidewalls and the lid.

Homemade design from an old tire looks great

Homemade design from an old tire looks great

So it turns out an unusual coffee table, which, if necessary, can be used as a banquette.

The idea of using "random" items to create home furniture proved to be extremely productive. She gave life to numerous homemade products from boxes and pallets. A little imagination and a minimum of expenses are required in order to assemble a coffee table made of wood based on four standard drawers.

The assembly algorithm looks like this: the boxes are placed on edge, placing them in a circle one after the other. Having connected the structure with the help of self-tapping screws, a shelf is made in its center. Here you can put flower vase or pour decor from river pebbles or shells. The woodworking is completed with sandpaper, stain and varnish.

Coffee table assembled from four boxes

Coffee table assembled from four boxes

Natural wood does not need sophisticated decor. Using it for interior decoration, complement the decor with a simple table. To assemble it, you will need several planed bars and slats of a picket fence.

The base frame will look reliable and massive when using a contrast color combination with tabletop. To do this, the bars need to be tinted with a dark stain, leaving the lid in natural color pine sawlog.

Wood in furniture goes well with metal. You can verify this by making a loft-style coffee table on metal legs. Its cover is assembled from three pieces of tongue-and-groove board "forty" and framed with a cornice plank.

Wooden table on metal legs made of smooth reinforcing bar

Wooden table on metal legs made of smooth reinforcing bar

For the manufacture of legs you will need welding machine, a piece of steel plate 1.5-2.0 mm thick and several scraps of smooth reinforcing steel with a diameter of 10-14 mm.

Having bent four rods according to the template, square pieces of plates (or thick carpentry corners as in the photo) are welded to them and alternately attached to a tabletop assembled from a grooved board. For final finishing, you need to grind, toned and varnish the lid, sides and paint the legs.

Instead of a bar for making the base, you can use profile pipe rectangular section. Having welded two rectangles from it, cleaned the seams and covered the metal with silver paint, we will get reliable supports for the countertop, assembled from thick oak boards.

To increase stability, the metal sidewalls under the cover are connected with a piece of a profile pipe.

Coffee tables with sawn wood tops look very impressive. Finding this basic element is easy. At any sawmill you will be offered a "semi-finished product" of the right size. An electric planer and a belt grinder will help you bring it to condition.

![]()

The legs of the table can be made from thick bars or a rebar can be used for them. The contrast between a massive tabletop and a light one metal base will give the design a touch of exclusive design.

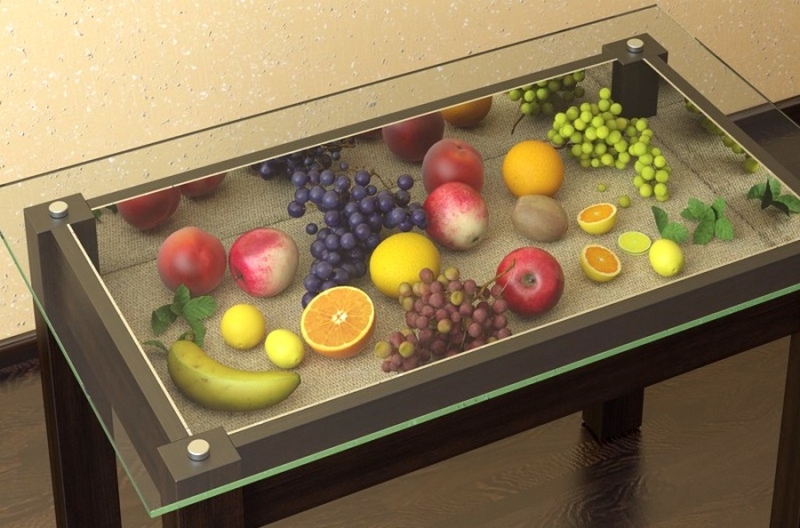

Another interesting option combination of materials - wood and glass. The tabletop can be oval or round, resting on a cruciform base of two bar frames.

"Weightless" glass goes well with massive wooden frame grounds

"Weightless" glass goes well with massive wooden frame grounds

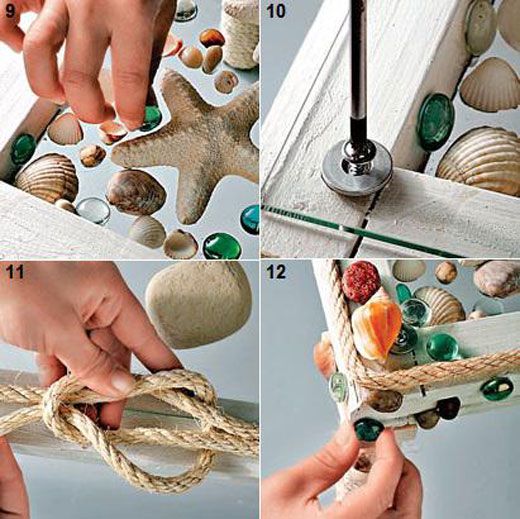

Crafted from a wooden pallet and covered with square glass, this movable coffee table looks stylish and modern.

The glass gives a rich look to the entire structure and closes the gaps between the pallet slats through which small objects can fall onto the floor.

Those who prioritize functionality will surely enjoy coffee table-transformer. Through simple manipulations, it radically changes not only its height, but also its appearance.

AT assembled condition This is a common stand for magazines and newspapers. By lifting the two sides with legs, we increase the height of the table and expand the surface of the tabletop to a “dinner format”.

The basis of another transforming system is two metal frame-pedestals. Each of them is hinged to the tabletop. In the assembled position, they lie horizontally, and when the lids are lifted, they turn on hinges and stand upright.

The height of the unfolded structure is 73 cm. This is quite enough to use the transformer as a computer desk.

Its cover consists of two plates that can be shifted horizontally. In this case, one plate rotates on a hinge around its axis. If necessary, such a transformer can be turned into a dinner table for 4 persons.

![]() Coffee table transformer "three in one"

Coffee table transformer "three in one"

Someone creates folding adaptive systems, and someone is successfully experimenting with ordinary plywood scraps. The result of the search for new forms was such an unusual coffee table.

We can only be surprised at the scrupulous accuracy of the calculation and its talented embodiment in a visible image.

Theoretically, everything looks simple: the base is sequentially glued together from three dozen plywood frames. Each of them has a certain angle of inclination of the legs.

In practice, to calculate all the elements of a plywood stand, a three-dimensional modeling program is needed.

The plywood “pie” assembled together attracts the eye with an unusual futuristic shape. glass lid crowns this piece of innovative carpentry technology.

“We would like something simpler, but also beautiful,” he will say House master. Please, there is a table no less elegant, but more affordable to manufacture. It consists of three packs of thin planed boards.

Numerous slots in the type-setting table top can be covered with a glass cover.

A few words need to be said about the connection of glass with wood. The best decision- use of transparent "optical" glue. drill at home thick glass, without causing him irreparable damage is quite difficult. So give up the idea mechanical fixation and let modern chemistry show its best qualities.

Self-manufacturing

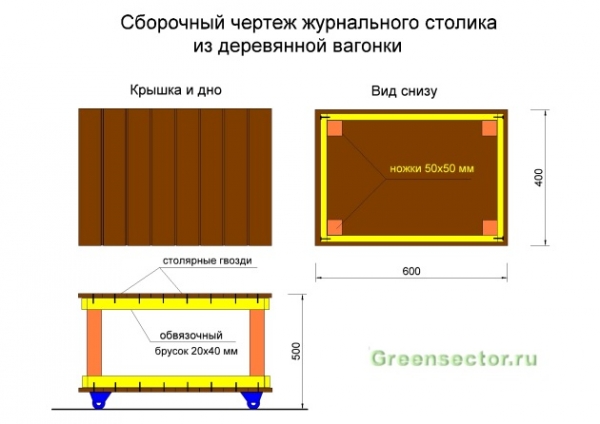

Speaking about the material for the countertop, we completely forgot about the wooden lining. This is an excellent material at hand, equally suitable for creating a lid, sides and legs.

Tabletop made of eurolining - beautiful and reliable

Tabletop made of eurolining - beautiful and reliable

The shape of the tabletop from the lining can be any. The lid, assembled from wooden planks, is cut with an electric jigsaw along a given contour.

To make a coffee table from a lining, we need several tools:

- screwdriver;

- jigsaw;

- belt grinder;

- hacksaw;

- roulette.

Dimensions finished product and the design of the docking nodes should be thought out in advance and entered into the outline drawing.

The finishing of the table is carried out in two stages. Before assembly, sand the surface of the lid, bottom and legs with sandpaper. After completion of the work, the wood is covered with a tinting stain and a colorless varnish.

It is even easier to make a coffee table made of chipboard. This material performs two functions at once: it forms a continuous surface and carries the load. We recommend using a veneered board, because on the "bare" Chipboard paint and varnish cannot hide the texture of wood chips.

After completing the assembly, you need to close all the edges (tabletops, bottom and legs) with plastic furniture tape, warming it up building hair dryer before pasting.

Making furniture with your own hands allows you not only to save the budget, but also contributes to the disclosure creative possibilities and creative ideas. On our own you can make an interesting version of the coffee table. Creating an exquisite and chic model can revive a dull interior, it is beneficial to make an accent in it. In this article, we will look at how to make a coffee table with your own hands from improvised materials.

Simple shape coffee table

In the interior there is always free place for side table. Such a piece of furniture will fit perfectly near the sofa to place a flower vase on it or put a mug of coffee and a candy bowl with sweets. In addition, the coffee table can be used as a stand, on which it is convenient to place flowerpots with indoor plants. bedside table can also be successfully replaced with a table made in an interesting design solution.

Tools and materials:

- board with dimensions of 15x40 cm - 2 pieces;

- board with dimensions 19x50 cm - 2 pieces;

- plates;

- legs;

- wood glue;

- paint (stain, varnish).

How to make a simple DIY coffee table:

- On the desk bigger size fix the plates for fixing the legs. We retreat a little from the edges.

- top and side surfaces We fix the table with carpentry glue, which dries within half an hour.

- After that, we process our product with paint, stain or varnish.

- Optionally, we decorate and decorate the made table.

Cement coffee table

Recently, interior elements made of concrete have become increasingly popular. Despite all the attractiveness and openness for decoration, such products also have disadvantages:

- The first disadvantage is a very expensive process in which a large amount of concrete is cast.

- For small side tables, the second negative point is that the weight of the furniture is too heavy. Moving such a product from one place to another is very inconvenient and requires physical strength.

Tools and materials

You can make a good solid piece of furniture with your own hands. To do this, prepare the following materials and tools:

- foam insulation board, the size of which is 120x240x2.5 cm;

- cement brand HENRY 549 FeatherFinish - 1 pack;

- aerosol glue brand 3M Super 77 - 1 can;

- hacksaw;

- sandpaper, in which the grain size is from 36 to 120;

- different size spatulas;

- dye;

- utility knife;

- grinding device;

- respirator 3.

How to make a cement coffee table with your own hands:

- We make markings and cut out a sheet of foam. From a piece with a size of 120x240 cm, we cut out 18 squares with a size of 40x40 cm. When we fold them on top of each other, we get a parallelepiped, the size of which is 40x40x45 cm.

- Glue the cut pieces. For this purpose, we will use spray adhesive 3M Super 77.

Important! It is desirable to perform such a procedure not indoors, but in open space. It is also mandatory to protect your hands with gloves and wear a shirt with long sleeves.

- On the first side of the square, apply an even layer of glue.

- We process the side of the second square in the same way with glue.

- After 15 seconds, we connect the squares - the edges should be joined.

- We repeat this procedure with all the squares.

- We combine square blanks into a single whole. After 30 minutes, we move on to the next step.

- We give the resulting parallelepiped the outlines of the future table. At first, the design has a rough angular shape. Grinding smooth out all the irregularities, give the product desired view. We start with the use of sandpaper 36 grit, gradually move on to the use of sandpaper, which has a finer grain size.

- When the surface of the future coffee table is sanded, it must be cemented. When applying the first layer, all the voids of the foam mold are filled. Within 20 minutes, you need to quickly smooth out all the bumps.

- When the first layer dries, apply the next layer. The number of applied layers determines how smooth and even the surface of the table will be.

Important! Cooking cement mortar, you need to follow the manufacturer's instructions, you should not prepare a large amount of the solution. Since such a procedure is dirty, the floor in the workshop must be covered with old newspapers or oilcloth.

- After applying and drying the last layer, we finally grind the surface of the table.

Important! When performing the grinding procedure, it is necessary to use a mask that protects the lungs from cement dust.

The made coffee table turns out to be strong and durable, while weighing no more than a kilogram.

Coffee table made of copper pipes

A do-it-yourself coffee table can be made from any material. Table made from copper tubes, is a very interesting design decision.

Tools and materials

- 6 meters 1/2″ copper pipe;

- clamps that serve to fasten 1/2 ″ pipes - 4 pieces;

- copper caps 1/2″ - 8 pieces;

- copper tees for 1/2″ pipes - 14 pieces;

- boards made of wood or slabs measuring 30x28 cm - 2 pcs;

- pieces of pipe 2.5 cm long - 4 pcs;

- liquid nails or epoxy-based glue;

- pipe cutting device.

Manufacturing process

How to make a coffee table with your own hands from copper pipes:

- We cut out the necessary blanks.

- Let's start the build process lower tier table.

- Having collected the lower part of the product, we begin to assemble the upper tier.

- We place pieces of pipe with a size of 2.5 cm into the tees, which are located on the upper side of the corner posts.

- On inserts that have exactly the same diameter as the tees, we put on decorative caps.

- pre-painted wooden shelves we fix our product special devices- clamps located on the underside of each board.

- After all the tubes of the desired length are cut out and fit well to each other, we carry out pre-assembly coffee table designs. We use special glue for a reliable connection.

- Coffee table made of copper tubes is ready to use.

Coffee table made of wooden slats

Stylish table, made of wooden slats, fits perfectly into any interior. Consider the appropriate materials and tools needed to create such a piece of furniture.

Materials:

- 3 boards with dimensions of 2.5x7.5 cm;

- 1 board whose size is 2.5x10 cm;

- 8 boards with dimensions of 2.5x5 cm;

- 4 fastening elements for table legs;

- 4 elements of tapered legs, the length of which is 35-45 cm and depends on the required height of the table;

- 8 screws, the length of which is 3.5 cm;

- 32 wooden screws with a flat head, the length of which is 3 cm;

- 16 trim nails, which are 3.75 cm long;

- special glue Gorilla Glue;

- putties used for wooden surfaces;

- paint and primer on wood;

- sandpaper 120 and 220 grit.

Instruments

- hacksaw;

- special drills and drill;

- Kreg kit, the use of which allows you to drill countersunk holes at an angle;

- 2 long and 2 short clamps;

- roulette;

- a hammer;

- grinding machine.

How to make a coffee table from wooden slats with your own hands:

- Using a hacksaw, at an angle of 45 degrees, we reduce the ends of two boards, which had a size of 2.5 × 7.5 cm.

- From bars with dimensions of 2.5 × 5 cm, we cut out parts whose length corresponds to the internal length of the blanks with dimensions of 2.5 × 7.5 cm.

- We place the details of the blanks with dimensions of 2.5 × 5 cm in the middle, and the blanks with dimensions of 2.5 × 7.5 cm along the edges. In this case, the ends of the inner rails must be aligned.

- We measure the distance between the extreme bars with a size of 2.5 × 7.5 cm, cut out two parts of the workpiece with the obtained value from a board with a length of 2.5 × 10 cm. They are the lower supports for our table.

- We fix them with screwed self-tapping screws, which are screwed into each longitudinal rail.

- Using the Kreg Jig kit, drill 2 pocket holes at the end of each cross support. We will use such holes to connect the extreme bars with parts having a size of 2.5 × 7.5 cm.

Important! It is difficult to specifically recommend the distance from the edge at which the Kreg Jig is to be installed. The length of the screws used, the exact thickness of the board and other factors affect this value. To guess the size, you can first practice with unnecessary scraps of boards.

- We place the details of the blanks with a size of 2.5x7.5 cm along the edges of our design.

- We check the ends so that they are at the same level. We fix them with clamps.

Important! If soft wood, such as pine, is used to make a coffee table with your own hands, then unnecessary scraps of boards should be placed under the clamp supports so that there are no marks left on the wood when clamping.

- Firmly and securely fasten the extreme bars with a size of 2.5x7.5 cm to the base of the table.

- We screw the screws with a length of 3.5 cm into the hidden pocket holes that were previously drilled at the end of each transverse support.

- To determine the length of the ends of the table, we measure the width of the manufactured base, cut out right size from a blank 2.5 × 7.5 cm.

- We apply a small amount of special Gorilla Glue to the ends of all the rails, which must first be moistened with water.

- We install end boards in the right place.

Important! So that the structure does not fall apart prematurely, it must be covered with a belt while the glue dries. For a reliable effect, you can additionally fix the ends with several carnations that serve for decoration.

- To eliminate all irregularities at the joints, we grind the surface of the table with sandpaper, which has a grit of 120.

- It is necessary to fill all the gaps and recesses in the seams with putty. Nail heads must be sunk into the wood.

- After the putty has dried, we grind the surface again with sandpaper only already 220 grit.

- We paint a coffee table made by ourselves. But before painting, it is advisable to once again treat the surface with 400 grit sandpaper.

- We install special plates on the lower supports of the crossbars. When fixing the mounting plates, you need to make sure that the holes do not fall into the places of already screwed screws. The distance from the attachment point to the edge of the table base is about 2.5 cm.

- We screw the legs of the coffee table into the fasteners.

Stump coffee table

A do-it-yourself stump table fits perfectly into the interior in a rustic or ethno style. Moreover, finding the material for such a product is very simple.

Tools and materials

For the manufacture of such a product, the following materials and tools are required:

- white acrylic paint;

- manual grinding machine;

- a hammer;

- chisel;

- wooden stump;

- nails for decorative upholstery;

- masking tape.

How to make a coffee table from a stump with your own hands:

- We find the basis for the table. An old rotten block of wood is not suitable for a table; there must be a freshly sawn stump. You need to wait six months for the stump to dry, and only when the bark is separated from the trunk, you can start the manufacturing process.

- With the help of a chisel, we clean the stump from the bark.

- Applying grinder and sandpaper of medium grit, grind the surface, remove the remnants of the bark and smooth out sharp corners.

- Wipe the wood with a damp cloth.

- We prime the surface of the wood.

- We paint our product with white acrylic paint.

- Attach a strip of masking tape. The upper edge of the side surface, along which the adhesive tape is pasted, marks the location of the first row of nails.

- We hammer the decorative nails of the first row with a hammer. Next, we proceed to the design of the “line” of the second row, and then we drive in decorative carnations in the third row. pasted before masking tape serves as a guide for maintaining the distance from the studs to the top edge. Approximately 140-150 decorative nails are needed.

Important! In order not to hurt flooring when moving the table around the apartment, it is advisable to upholster the lower surface of the stump with furniture felt material.

Plywood coffee table

You can also make a coffee table with your own hands from plywood and glass. For this:

- First, dimensions are determined and a drawing is developed. After that, we proceed to the manufacture of a coffee table.

- A box with partitions made of plywood is used as a countertop.

- We close the made box from above with glass.

- Sufficiently thick plywood is used when cutting out the legs for the table.

Important! It should be borne in mind that making double legs is much easier than many single ones.

- We attach the triangular legs to the box made earlier.

- For convenience, the plywood box can be decorated with a door.

- The final step is painting or varnishing.

Pallet coffee table

The furniture option that you can make with your own hands from pallets looks very interesting.

Option 1:

- First, pallets are sanded, sawn into pieces and primed.

- A table is assembled from the prepared parts. To do this, attach the wheels or legs. The pallet itself can serve as a lid, or you can use a part assembled from individual boards.

- When all the details are connected, the structure must be painted or varnished.

- After drying, the pallet table is ready.

Option 2

To make this version of the table, a part of one or two pallets is used:

- We first create a sketch of the future table, taking into account all dimensions.

- We equip the table with a shelf for small things, which will be located under the table top.

- When all the details are prepared, we assemble the desired design.

- The surface of the table is painted with paint.

- Optionally, we additionally decorate and decorate the finished product.

Nautical style coffee table

To make a table, you can use the old window frame. This option looks very romantic.

How to make a coffee table nautical style do it yourself:

- We clean the frame from dust. If necessary, we replace the glass.

- We paint the wooden surface of the frame with white acrylic paint.

- When the paint layer has dried, we process the surface with sandpaper until the wood comes through. A blue and white color scheme is also available.

- We make the legs from a cutting, which we cut into 4 parts of 34 cm each. To remove the roughness of the workpiece of the legs, we process it with sandpaper.

- The bases of the legs are made from sawn scraps furniture board. We also remove all irregularities with sandpaper.

- We drill blanks in four places.

- We attach each leg to the base.

- The base with legs is attached to wooden frame. We fasten everything with self-tapping screws.

- We glue the legs with a rope of a rough structure.

- We glue marine-themed souvenirs and all kinds of seafood on skimmed and cleaned glass. Based on the size of the frame, we cut out glass in the workshop, with which we close sea souvenirs.

- On one side of the coarse rope we make a loop. We glue the rope along the entire perimeter of the frame while leaving the loop free. From the side of the second end we tie an interesting sea knot.

- The nautical themed coffee table is ready.

Log coffee table

For a country house or cottage, a table made from logs with your own hands will become a decoration. How to make a coffee table out of logs with your own hands:

- First, we assemble the frame from plywood sheets with a thickness of 2 cm.

- From the sheets we cut out the base of the table, which has dimensions of 60x80 cm.

- We attach a box with a length of 68 cm, a width of 45 cm and a height of 40 cm to the cut out base.

- Then we cut round logs in the amount of 30 pieces with a length of 45 cm and round cuts in the amount of 24 pieces, the thickness of which is 3 cm.

- We fix the prepared logs around the entire perimeter of the box.

- We attach rollers to the bottom surface of the base, set them at a distance of 3 cm from the edge of the product.

- We attach the logs with glue. For a reliable connection, the logs are additionally fixed from the bottom to the screws.

- We install a plywood cover on top of the box, on which we glue the rounds.

- Putty for wood fill the space between the logs.

Important! When dried, such putty does not shrink. It must be applied in stages, allowing the previous layer to dry.

- After the last layer has dried, the surface of the product must be sanded using a surface grinder.

Our table is ready to use!

As you can see, there are a lot of ideas for making a coffee table with your own hands. Which one will be yours depends on the materials available, the skills to perform such work and the style of the interior of the room for which you want to make such a piece of furniture. Good luck!