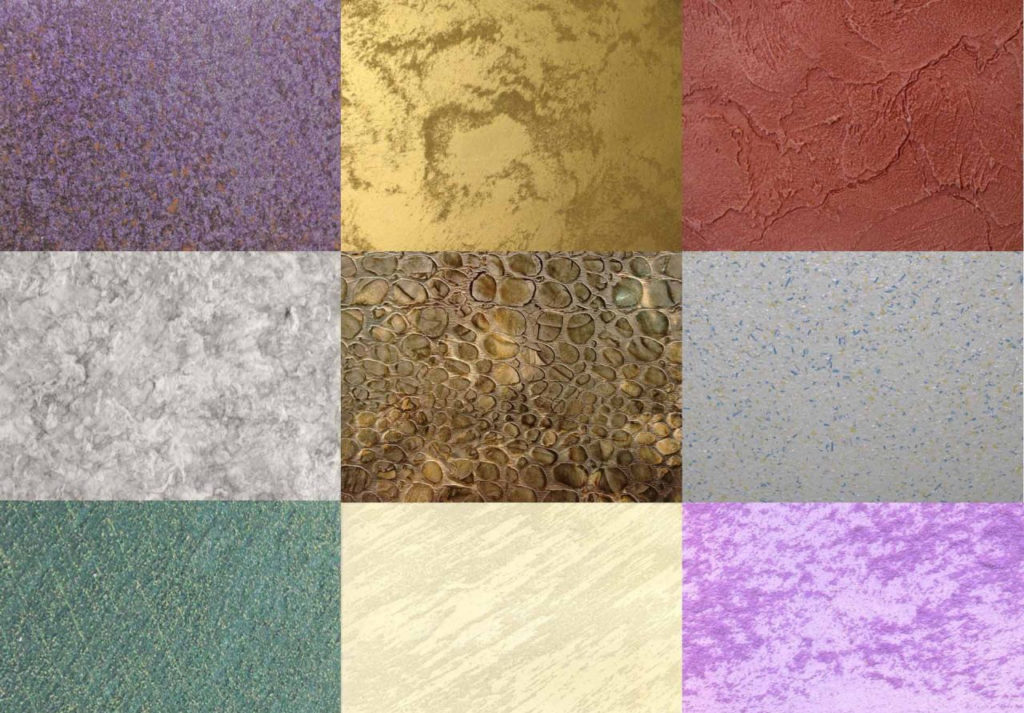

Figured plaster. Features of work with decorative plaster. Various options for applying decorative plaster

Decorative plaster looks not only very attractive, but also greatly expands the possibilities of masters in interior design. The cost of the finished building mix for decorative finishes The walls are quite high, which significantly limits the possibilities of its use. In some cases, experts reveal their secrets of craftsmanship and show by examples that decorative plastering with their own hands is in no way inferior to ready-made solutions.

It is to such a master that I would like to express special gratitude for the understandable and accessible video instructions that allow you to implement various ideas for the design of the premises. The review includes the cumulative experience of the masters, which is collected in a separate publication. The recipe and tips will help you endlessly experiment with decorative design in any room where each wall can acquire a unique appearance.

Decorative plaster in different techniques

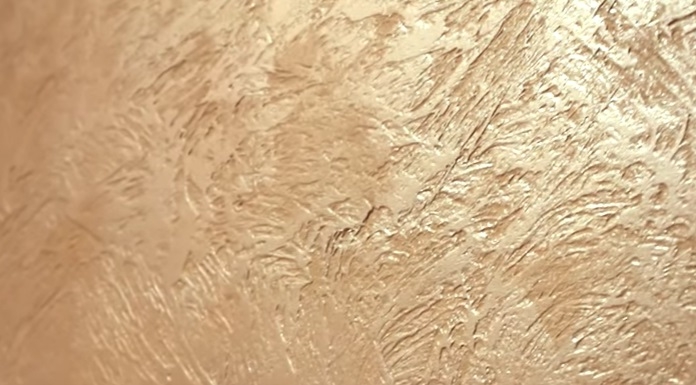

Versailles plaster from conventional mixtures

How to make decorative plaster with your own hands like the walls in the apartments of Versailles? It turns out that a similar texture can be achieved using the usual dry starting gypsum plaster And finishing putty, which, when mixed and applied, give an attractive texture with light inclusions of the middle fraction. This finish requires the use acrylic lacquer, metallic paint and glitter. Detailed master class from the studio "REDecoration" is shown in the video at the end of the publication.

The sequence of work on applying Versailles plaster:

- glue the perimeter of the future coating with plaster tape;

- prime the surface with quartz primer, which will ensure good adhesion and allow you to work with the model mass longer. For these purposes, Ceresit "Primer paint for thin-layer plaster and paints";

- modeling mass for decorative plastering works mixed with water in a 1:1 ratio of finishing putty and starting gypsum plaster. The manufacturer of the mixture is not important, but you can use, for example, G-Start and Satenpro dry mixes;

- the mixture is mixed with a mixer twice, the first time immediately after adding the mixtures, the second time - after the mass has stood for several minutes;

- plaster is applied to the wall with a layer of 2-3 mm using a spatula and trowel, making random stains to create the desired texture, special attention is paid to the corners and space near ceiling baguette and doors;

- the model mass is applied in an even layer on the wall, and then an additional “textured” layer is made using a plastic trowel, which creates the desired volume;

- after the plaster has dried, the resulting irregularities are smoothed out and sanded with a spatula, paint grater and sandpaper(No. 60), the result is a beautiful smooth coating with a pronounced, but shallow texture;

- at the next stage, a deep penetration primer is applied, well smearing all the irregularities and avoiding smudges;

- after priming, the surface is painted, for this white paint is mixed with any selected dye, it will take about 2 hours to dry this layer;

- with the next layer, the wall is painted with a metallic decor, silver is diluted on a primer in a ratio of 1: 1, then it is applied with a foam roller on the first layer of paint with light movements, without filling all the irregularities (pay attention so that there are no traces of the roller);

- the finishing layer of the surface is made with varnish with the addition of glitter. First, the varnish is diluted with water by 30% in order to avoid varnish "peel" on finished coating, then glitter is added at the rate of 1 tsp. per 1 liter During operation, the varnish must be stirred regularly in order to “lift” the settling sparkles.

Obviously, in this way you can make plaster in any color with a metallic paint finish of any shade and decorate with colored and plain glitter. You can also change the manner of applying plaster, creating different textures. The varnish gives the coating a fairly high strength and protects the wall from fading in the sun, both matte and glossy varnish can be used for coating.

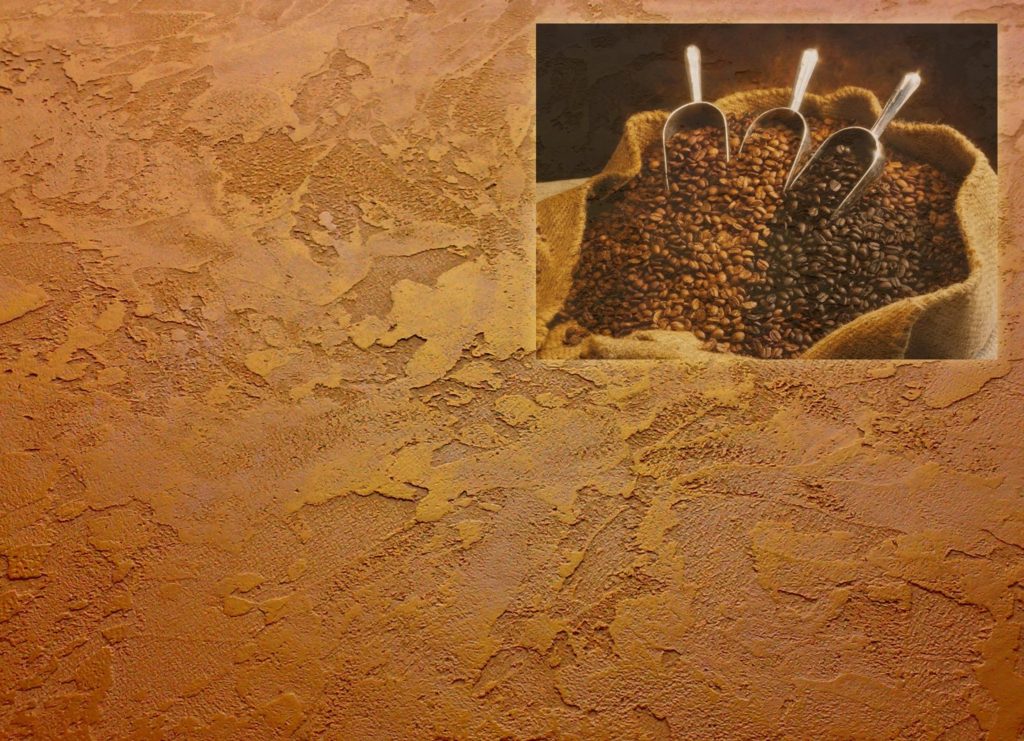

Flemish plaster - two-tone tinted in mass

Working with Flemish plaster differs from the above Versailles and Venetian plaster in the way it is applied and finished, it is also made from ordinary putty based on the model mass, the recipe of which is given above. The approximate consumption of such plaster is 80 g per 1 sq. m.

The key difference between this coating is that the finished decorative putty is tinted in bulk, that is, the dye is added to the plaster finish mixture, and not applied as a separate layer. In the video tutorial, yellow-brown and coffee plaster is used, which is applied with a large spatula on the prepared surface with movements “from yourself to yourself”, thus creating a beautiful two-tone texture.

At the next stage, the wall is smoothly smoothed with a trowel or spatula. It does not need to achieve perfect smoothness. The main goal is to mix two colors of plaster and get an interesting two-tone finish.

Flemish plaster is applied in three layers, using spatulas of different sizes, reducing their size from layer to layer. On the second and third - you can use a 20 cm tool. Subsequent layers are applied in such a way that a texture forms on the wall and irregularities form inside smooth surfaces. The size of the "islands" will depend on the volume of the mixture used in one putty application cycle. The more model mass will be on the spatula - the larger "islands" smooth surface can be done on the wall. The last layer can be applied with a Venetian trowel according to the “press-smooth” scheme, in which case a different texture is obtained.

After applying the plaster, the wall is painted with a deep penetration primer. After complete drying, the plastered area is covered with azure using a trowel. The mixture can be prepared according to the following recipe (consumption 120 g per 1 sq. M):

- glue for non-woven wallpaper, diluted according to the instructions - 2 parts;

- panel varnish - 1 part;

- paint "Silver" - 0.5 parts.

In its structure, azure is a regular wax, which is covered with plaster as a finishing layer. Please note that the wax is not completely removed in the recesses, which results in a texture with areas of varying degrees of silvering. Instead of silver, mother-of-pearl or gold can be used to prepare azure, which allows you to achieve different lighting effects.

If desired, the wall can be additionally decorated with varnish, which will give the coating strength. For wet rooms yacht varnish or waterproof facade plaster can be used.

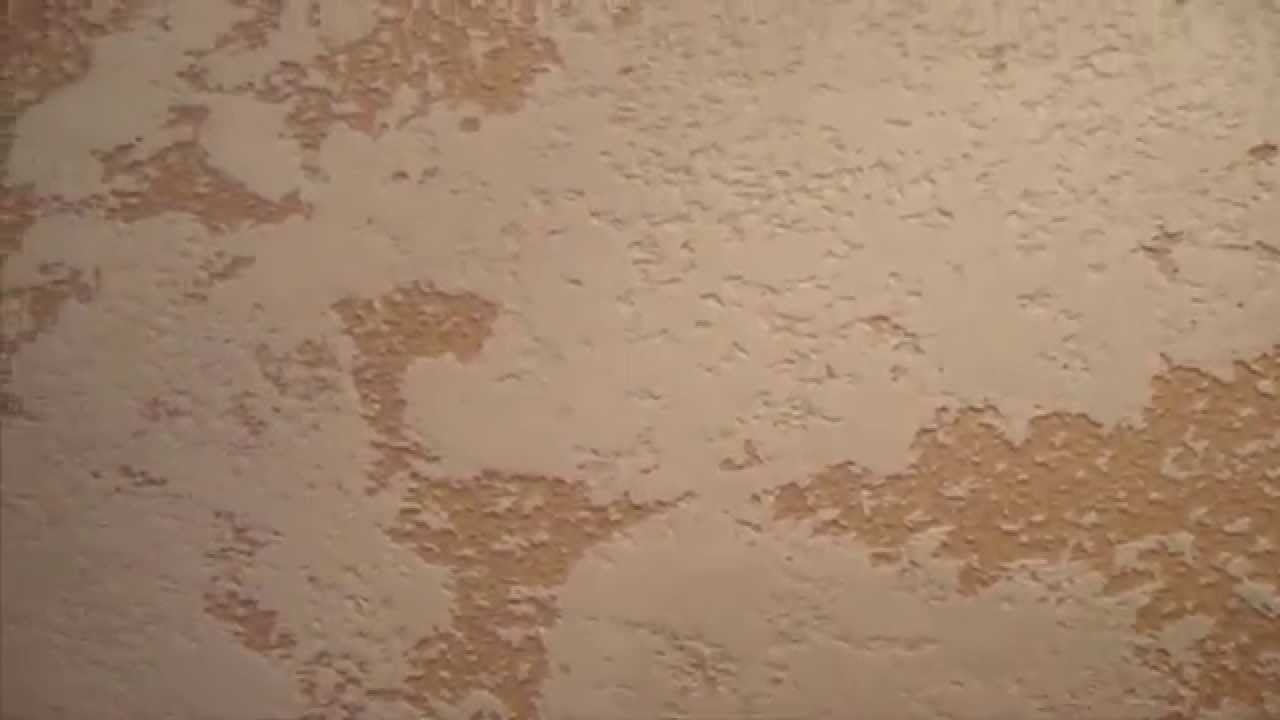

Prague plaster

Prague plaster or, as some craftsmen call it, "Venetian fresco" is applied to a pre-tinted surface. For this, the soil is added exterior paint and color desired color. The main task is to make a colored base layer simultaneously with the application of the primer. When applying a primer layer, it is not necessary to achieve uniform "coverage".

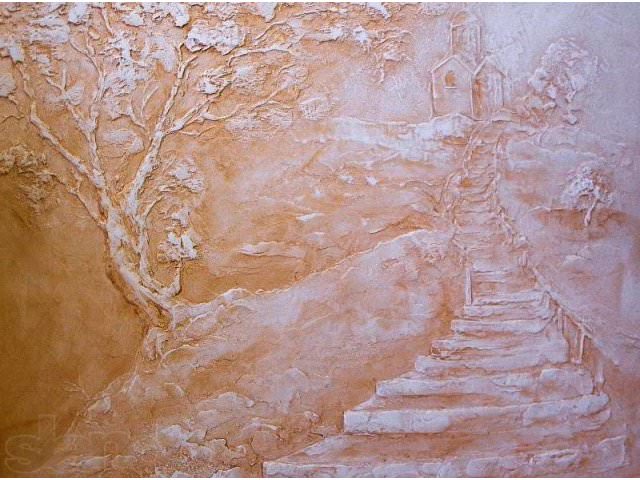

In order to prepare a model mass of decorative Prague plaster, any acrylic putty is used, 1/10 of the sand and color are added to it (preliminary consumption of 1.5 kg per 1 sq. M). The first layer of putty is applied with a Venetian trowel, forming an uneven surface in the form of "islands". Due to the sand, a more voluminous texture and a rich finish are obtained.

The second layer of putty is applied to the wall by trimming with a trowel. Movements involve pressing the trowel with mortar against the wall in a chaotic manner. Please note that the required two layers are applied one after the other. First, approximately 1 sq. m of surface and the first layer is applied, then the same area is decorated with a texture by trimming.

In the same way, the next section is covered with a solution. After that, you need to return to the previous section and smooth the plaster "on the tops" with a 20 cm spatula, removing the remaining mortar from the tool. After about five minutes, the finished surface must be polished with a Venetian trowel, while not applying special effort. The degree of readiness of the coating for this operation can be determined by touching the hand, the putty should not stick to the fingers.

On the final stage the finished surface is painted after applying the layer deep primer and its complete drying. Used for finishing special compound paints based on Venetian plaster diluted with water (consumption 150 g per sq. m.). Using Venetian plaster as a paint will result in a more interesting slightly shiny surface.

At the final stage, the lined surface is covered with a special wax for decorative plasters, this is done using a plastic wallpaper spatula. For these purposes, the so-called Parmesan blue can be used, which gives a very beautiful effect of noble brilliance.

Decorative plaster for finishing facades and fireplaces - stone finish

The proposed method of decorating surfaces can also be used for finishing facades and fireplace portals, but other mineral fillers are used for these purposes. good option choice of finish "under the stone" can be considered dolomite plaster, but, unfortunately, its price is quite high for finishing the facade.

To reduce the cost of the original decorative mixture, use dolomite flour, which is added to the stylo-acrylic dispersion (UCAR™ Latex DC 640) for external works with high water repellency, or acrylic putty(Sniezka Acryl-Putz) for internal works. Dye, metallized filler, glitter or mother-of-pearl are also added to the finished material.

It is necessary to apply dolomite putty on the fireplace in two layers, first with an even layer with a large Venetian trowel, then make a drawing layer by trimming the surface, followed by smoothing with the same trowel.

The surface is lightly sanded with sandpaper No. 150, primed and then decorated with Venetian plaster. It is applied diluted with water like paint using a conventional roller. After application, the plaster is polished with a trowel.

The natural texture of the stone is always distinguished by shiny blotches, so the “dolomite-like” surface is also decorated with a coating with a metallized filler. To do this, copper is added to the wax, it is applied according to the texture of the surface, bypassing the smooth areas of the cladding. At the final stage, the surface is waxed without glitter and polished with a soft trowel. Two-color stone-like plaster can be obtained using the Flemish application method described above. As you can see from the examples, do it yourself decorative rock on any surface is not at all difficult and it will not cost much, and the effect will exceed all expectations.

Facade decorative plaster

After gaining experience in applying decorative plaster for interior work, the question arises about the exterior finish. For this purpose, you can use liquid glass, with which a waterproof version of the plaster is made:

- first a primer layer is applied, using a dilute solution liquid glass;

- a model solution of waterproof (hydrophobic) plaster is mixed in the following proportions: a ready-made solution is used plaster mixture in a ratio with liquid glass 7:1 or plaster is prepared 1:2:5 from liquid glass, cement and sand.

Video instructions for applying decorative plaster

In conclusion, we give examples of how do-it-yourself decorative plaster is made video using all the methods mentioned. Good luck. These examples will help you make expensive repairs in your home at a low cost.

One of building materials- plaster. Do-it-yourself decorative plaster is the brainchild of do-it-yourself inventors. high cost ready mixes compels the search for alternative formulations. Home craftsmen are the inventors of several decorative compositions for plastering. In terms of quality, they are not inferior to those made in industrial environment similar mixtures.

Do-it-yourself decorative plaster is the brainchild of home-made inventors

Wall decoration with decorative plaster is very beautiful and profitable. The coating is completely maintainable and environmentally friendly. Its application to the surface is possible in several different ways. Each of them is able to create a different texture. You can add color to the compositions or paint the surfaces finished with a plaster composition in any color.

As base materials in home-made mixtures are used:

- building plaster;

- putty;

- silicone;

- clay;

- cement;

- lime;

- silicate glass;

- acrylic.

IN decorative purposes poured into the mixture various components. Suitable for mineral-based plaster:

- sand of different fractions;

- flour;

- shells;

- stone chips;

- small minerals.

![]()

Wall decoration with decorative plaster is very beautiful and profitable

Synthetic fillers are most suitable for polymer compositions. They give the coating the effect:

- natural or artificial leather;

- silks;

- stone chips;

- wood textures of different species;

- suede.

To create a special viscosity of the mixture, plasticizers are added to it. This role is played by PVA glue. Separate components for plaster decorative mixture can be purchased at the store, as well as found in nature. natural materials in the form of sand, shells and crumbs of various stones, you need to sift and dry well. It is desirable to select fractions with sizes from 0.7 to 3.0 mm. Lime or clay is pre-soaked, then rubbed through a sieve.

Simple decorative plaster is a ready-made putty mass. For strength, 2.5-6% PVA is added to it. With a higher percentage, the strength of the layer increases, but it dries much longer.

For creating polymer composition can be used:

- PVA - 800 grams;

- CMC solution 5% - 2000 g;

- laundry soap solution;

- chalk or gypsum powder - 6500 g.

Soap is rubbed on a grater and soaked in clean water. Then stir until a thick gel. All components before use are thoroughly mixed to a paste state. This is best done with electric drill and mixer attachments. Homemade polymer mixture dries for a very long time.

For interior work, you can prepare the following working mixture:

- sand - 3 parts;

- Satengips - 3 parts;

- Fugenfüller - 1 part.

The sand must be washed and sieved. Satengips is a gypsum putty with additives. Fugenfüller has polymer additives. This mixture is added to the overall composition to give strength and moisture resistance. All components in a dry state are mixed, then mixed with water.

For outdoor work in areas with a very dry climate, they make such a plaster: they mix an ordinary mortar of cement and sand. Add lime to it and mix well. Portland cement white color grades M400 or higher take 1 part. 3 parts of sand and a little lime are added to it. Ready solution should have the consistency of thick sour cream.

DIY decorative plaster (video)

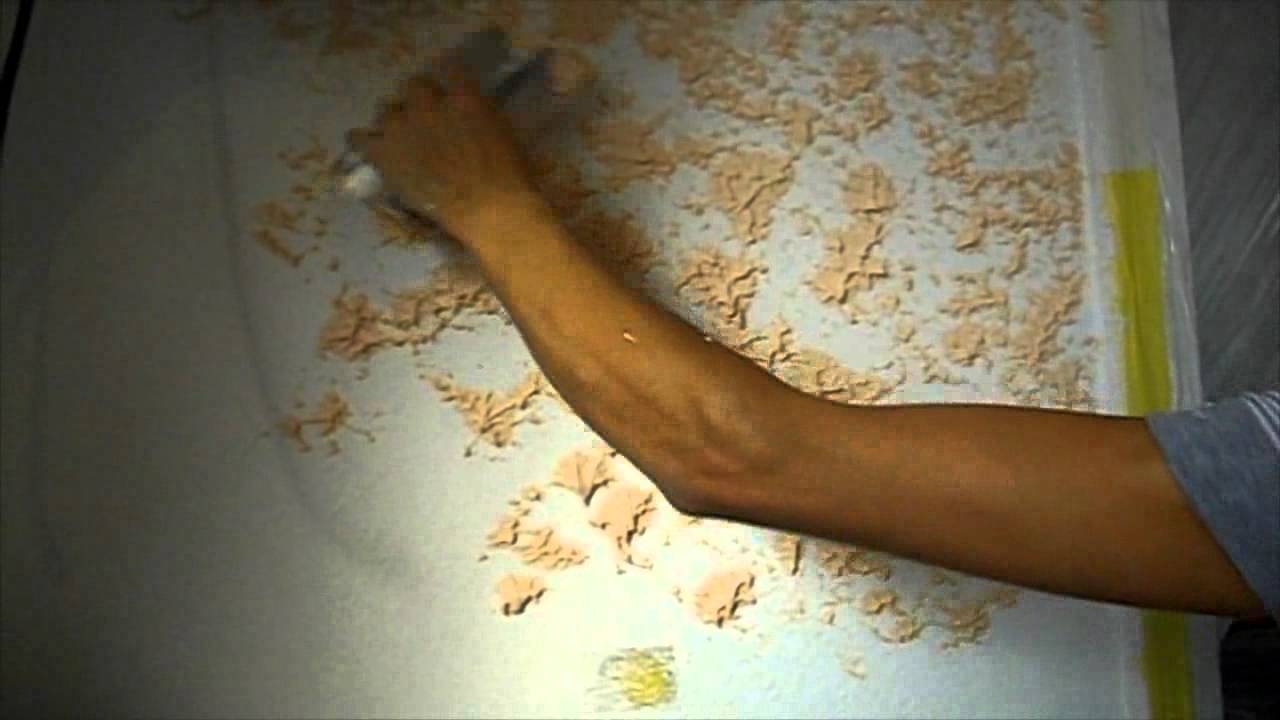

How to apply plaster

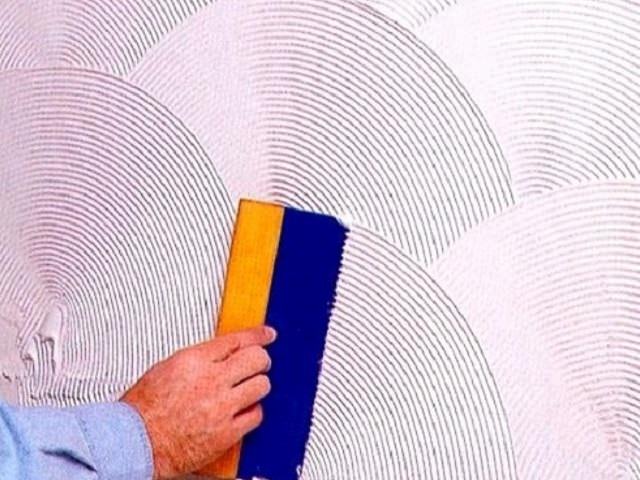

How is decorative plaster applied to walls? Apply decorative plaster with your own hands in a layer of about 3 mm thick. There may be several layers. On the top of them any drawing is applied. This is done using crumpled polyethylene or paper, a sponge, special stamps and rollers. Certain patterns can be applied with a spatula small size. Work with its help is performed with chaotic movements.

Another way is this:

- first one layer is applied to the surface;

- then it is dried, sanded and treated with a primer;

- an additional layer is applied on the stencil, creating a pattern.

To create a special viscosity of the mixture, plasticizers are added to it.

In this case, ornaments from geometric shapes, grape bunches, climbing plants. These drawings should dry well. After that, the sharp edges of some patterns need to be treated with an abrasive bar or sandpaper. Next, the details of the drawings are painted different colors, are covered with gilding or patina.

The thickness of the convex parts should not be more than 3-5 mm. Otherwise, the plaster in these places will soon begin to crack and collapse.

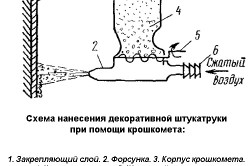

Applying decorative plaster with your own hands can be done by spraying. This is done with a spray gun or a brush with long bristles. The brush is dipped into the working solution and hit on a stick. The splashes fly to the wall and form something like a fur coat. On the facades of buildings, the texture of a fur coat or bark beetle is used. To obtain a bark beetle, you need to apply a thin layer on the wall, equal to the size of the grains in the solution. After some drying, this layer is rubbed with a spatula. The tool must be moistened with water and firmly pressed to the surface. The grains will cut grooves in the solution, forming a texture of bark beetle marks.

The simplest and cheapest decorative plaster (video)

Conclusion on the topic

Do-it-yourself decorative wall plastering is the last stage in the repair of an apartment. There are a lot of decor options. The question comes down to cost. finished materials. Therefore, home craftsmen independently try to create such solutions. To do this, they buy components in stores, look for them in nature. The usual cement and sand, lime and pebbles, and other additives are used. As a result, you can get both very successful and completely unsuccessful solutions. With the help of successful solutions, it is easy to obtain original cover on the walls of an apartment or house. How to apply decorative plaster on the surface? This is done with a spatula, spray or spray gun. You can also use a brush long pile.

If you apply several layers of plaster, you can get convex patterns through the stencil. Sharp edges are cleaned with sandpaper and painted in any color. Upper layer, forming a pattern, should not be thick. 3-5 mm is quite enough, otherwise it will collapse after a while. Used to create patterns various tools: rollers with a textured surface, small spatulas, brushes, special stamps. When working outside buildings, fur coats or bark beetles are often used. You can make them with a brush or spatula.

Applying decorative plaster on the walls is quite easy and simple. The result will always be great.

And some secrets...

Have you ever experienced unbearable joint pain? And you know firsthand what it is:

- inability to move easily and comfortably;

- discomfort when going up and down stairs;

- unpleasant crunch, clicking not of their own free will;

- pain during or after exercise;

- inflammation in the joints and swelling;

- causeless and sometimes unbearable aching pain in the joints ...

Now answer the question: does it suit you? Can such pain be endured? And how much money have you already "leaked" for ineffective treatment? That's right - it's time to end this! Do you agree? That is why we decided to publish an exclusive

One of the leading positions among finishing materials for a long time has been occupied by decorative plaster - an option for wall decoration, combining a simple execution technology and an excellent result. Initially, it vaguely resembles paste, which is applied to walls and ceilings. This material can be used completely on its own or as a base for subsequent finishing steps.

Decorative plaster - a unique wall decoration

Decorative plaster is divided into types depending on the components of the composition and the expected effect:

- structural plaster - a mixed composition with various inclusions like fine stone chips, colored pieces of quartz or wood fibers. It is produced on a cement-lime basis. It also uses special synthetic latexes or potassium silicate. Solvents in mixtures are present in water or organic, so plaster can be considered an environmentally friendly material and used for interior decoration, without fear of unpleasant odors, either during repair work or in freshly plastered premises upon completion.

Types of decorative plaster - craquelure

An additional plus: structural plaster is a very plastic finishing material, and it is sold ready for use in packaging of various volumes.

- textured plaster makes it possible to form a smooth, but embossed surface;

- Venetian plaster as a result turns into a coating resembling marble.

Application of structural plaster

When preparing the walls, there is no need to perfectly align them. Due to its heterogeneous, interspersed structure, the material perfectly hides minor flaws in the rough finish of the walls. The main requirement is that the walls must be dry, clean, pre-primed and dried. The primer serves as a kind of obstacle to the penetration of moisture into the decorated layer.

To apply plaster, a trowel or spatula is most often used. After a few hours, such a coating will already be strong enough, but it should take at least a week before it dries completely.

In addition , similar compositions are produced for both internal and external work . Such compounds are not afraid of frost, do not support combustion and are resistant to humidity.

![]()

Textured plaster

Lineups textured plaster may vary, but in the end, they all make it possible to create an original relief pattern on the walls, the complexity of which largely depends on the components and on how decorative plaster is applied to the walls in each case.

Walls with this finish are quite common. Such a coating resembles wood, crumpled paper, stone, or something like that. In the interior, the coating looks original, giving the room a special, unique style.

Painting on the wall with decorative plaster

It is also remarkable that the composition of textured plaster can be chosen for any room design, and using different techniques application - to give it a complete, harmonious look.

The main component of textured plaster is lime flour, and the characteristics of each specific solution depend on the fillers used. Polymer materials as a basis, they make it possible to obtain a durable surface without cracks and chips.

Walls to apply plaster composition must be smooth, clean, primed and dried. After the primer dries, a so-called substrate is applied to the walls - a layer of paint with sand. This helps to enhance adhesion (coupling of plaster and base).

If you carry out work without the involvement of specialists, then special compositions that combine the properties of all the materials listed above will significantly save time.

The plaster is applied in one or two or more layers. For work, you can use trowels, a spatula, a brush and other tools that will make it possible to obtain the desired expressive pattern on the surface. A more complex pattern is created by applying several thin layers of plaster composition.

Glazing compositions - special translucent paints - can serve as additional protection for the finished surface. They will add a noble mother-of-pearl shine to the walls. In addition, special wax, paint or impregnation can be applied as a topcoat.

Venetian plaster

Venetian plaster is a mixture of marble flour, hydrated lime and an aqueous emulsion. At the end of the work, it seems that marble stone was used in the decoration. Initially, Venetian plaster is a ready-to-use viscous composition, which is sold in large jars or buckets from 7 to 25 kg.

The only disadvantage of this coating is that it must be applied only on perfectly flat walls. Any color can be chosen. The composition is easily tinted, so if you wish, you can create whole “marble” paintings on the walls. In addition, Venetian plaster is environmentally friendly, waterproof, wear-resistant, does not support combustion and dries very quickly.

Before applying Venetian plaster, the walls or ceiling must be brought to perfect condition, otherwise any flaws will be visible. Then, as in preparing surfaces for applying other types of plaster, the base must be primed and allowed to dry. The plaster mixture is tinted and applied with a spatula in very thin layers. After the plaster has completely dried, the surface is carefully cleaned with very fine sandpaper, while leveling. In total, from 5 to 12 such layers can be applied and cleaned. At the end, a layer of wax is applied, which gives the surface a marble sheen.

Despite the apparent complexity, it is quite possible to cope with the decoration of the walls with Venetian plaster on your own.

Compositions "antique"

Recently, many pay attention to the plaster "antique". The coating got this name because it looks a little shabby on the walls, as if a little faded from time to time. In addition, such a finish will not be smooth, but rough to the touch, as if the texture itself has changed during natural aging.

"Aged" plaster

The application technique and the artificial latexes in the mixture give the coating special property- it begins to lighten a little in places of greater friction.

In addition to finishing the walls inside the room, such compositions can be successfully used in the decoration of facades.

You can also buy it in packing buckets with a volume of 4-5 liters. When the coating is completely dry, a microporous film forms on its surface, which provides the effect of roughness, and at the same time protects the surface from mechanical damage and high temperatures.

Decorative plaster for external works

In addition to plaster compositions for interior work, on modern market of building materials, facade decorative plaster is also presented, which is characterized by increased resistance to humidity, precipitation and temperature extremes.

Applying to the ceiling

Another pleasant moment is that not only walls, but also the ceiling are suitable for finishing with decorative plaster. Of course, it must be leveled and cleaned of the remnants of the old coating. Ideally - level with drywall, but you can do without it.

The main difference from wall decoration is that it cannot be applied to the ceiling thick layer plaster, maximum - 5 mm. If more, there are too many chances that over time, part of the coating will simply fall off. Otherwise, the technique and all application conditions are identical to those for walls.

Tools and materials

In order for the plaster composition to lay flat on the base, you need to stock up in advance necessary tools and materials. We have already talked about materials. In addition to the plaster mix, you will need:

- acrylic putty;

- polymer primer;

- semi-gloss wax;

- dense polyethylene;

- dye;

- masking tape.

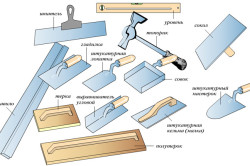

Of the tools you will need: a metal spatula (size 80), a one-handed trowel (trowel), a cuvette (paint bath), a brush-brush (40x140), a two-inch brush, a thread roller (size 150). In addition, you will need a regular bath sponge and cotton rags.

Plastering technology

Foundation preparation

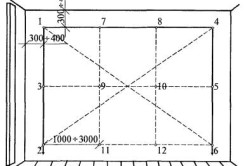

Preparing walls or ceilings for plastering

The start of plastering must be preceded by careful preparation walls or ceilings for decorative plastering. The surface must be prepared in the same way as for painting. It should not have irregularities or cracks, because decorative plaster is not applied in a thick layer and simply repeats all surface irregularities. The base must be primed with a deep penetrating latex primer and allowed to dry. After the primer has dried, all places adjacent to the surface where the plaster will be applied ( ceiling plinth, wallpaper), sealed with masking tape.

Then the walls are putty. The putty is applied to the trowel and carefully applied to the wall, trying to evenly distribute a thin layer over the surface.

How decorative plaster is applied

At the next stage, with the help of polyethylene, the desired texture is created on the surface of the not yet dried putty. To do this, crumpled polyethylene is laid on fresh putty. Moreover, the “crumpled” it is, the better, the richer the texture will turn out. The area of the polyethylene must be greater than the surface area to be treated. It is better if one piece is enough for the entire area.

This crumpled polyethylene must be glued to a fresh putty so that all the folds are well imprinted in the still wet layer. During the day, in this way, several surfaces that are not adjacent to each other can be sealed with polyethylene. In turn, adjacent surfaces must be treated after the previously treated ones have dried. Otherwise, chips may result in the corners, or the surface may be accidentally spoiled with a spatula.

The plastic film must be kept on the surface for about 15 hours, and then carefully removed along with the masking tape. You should not wait for the putty to dry completely, otherwise ugly chips will turn out on the surface instead of texture. However, after removing the film, the textured layer must be allowed to dry completely. This will take about a day. It is not worth using fan heaters or heaters to speed up the process - this can cause cracks on the surface of the putty and ruin the whole overall look.

After the putty has completely dried with a spatula or trowel, all unnecessary chips are carefully, but without undue care, removed. Then, with a dry brush, the entire surface of the wall is carefully swept over - this will remove all the dust that has formed.

Now again it is necessary to paste over with masking tape all the places where it was glued before applying the putty.

Painting

Painting a plastered surface

For painting after decorating the walls you will need pigmented wax . 20% warm water is added to it, then the mass is stirred, bringing to a homogeneous consistency. Wax on walls is most often applied in one of two ways: with a sponge or with a thread roller. If preference is initially given to the roller (it’s really faster), then the bath sponge will still come in handy - it’s more convenient for it to evenly distribute the wax over the entire decorated surface. The sponge must be soaked in clean water, and then with light movements, walk it over the entire decorated surface.

Painting a wall with stucco

Coral will be an excellent replacement for a regular bath sponge, but its price is much higher. On the surface of the wall after processing with a sponge, the texture of the finish should clearly appear. The wax is rubbed until the pattern becomes uniform. There should be no conspicuous spots of wax. The putty should not show through the wax layer either. After 15-20 minutes after rubbing the wax, the surface of the walls should be easily treated with damp and soft cotton rags . After this procedure, the volumetric pattern on the walls will become more pronounced. You should pay attention to the fact that rags should be used white or old, faded. Bright colors can shed and leave colorful spots on the surface.

In inside corners In rooms, wax can accumulate, causing dark spots to form there. To get rid of them, experts advise using a spatula with rags wound around it. They are easily removed dark spots in the corners.

Back to index

Decorative plaster - a modern finishing material

If there is a need to change the apartment or office interior, then you can use one of the modern environmentally friendly finishing materials - decorative plaster. This finish has long term services. Some types of decorative plaster will not need to be torn off or re-plastered in case of repair, you can simply apply enamel, paint or wallpaper on the former finish.

The main thing is to understand the secrets of professional skill in performing wall decoration work.

Various types of decorative plaster can be used not only for the purpose of decorating the facades of buildings, but also for the interior of the premises. These materials are designed to improve the microclimate inside buildings, which are characterized by freezing of interpanel corners and joints. The use of plasters will help to make any building nobler and at the same time hide all construction defects. Various types of plasters, playing the role of independent decorative value, final finishing wall surfaces, that is, painting, wallpapering will not be required.

Depending on the composition of the plaster base, it is divided into 4 main classes:

- silicate.

- Acrylic.

- Mineral.

- Silicone.

When choosing plaster, plan the effect of it in advance. It can be embossed or even. Since modern decorative plaster is a paste with the addition of pigment, it is important to determine its color and shade.

Back to index

Varieties of decorative plaster and features of their application

The choice of decorative plaster should be taken responsibly. Right choice it is not difficult to do if you know how it is classified.

The variety of plaster depends on the methods of its application and on general view surfaces.

Decorative plasters according to their composition are classified into the following types:

- Lime-sand (mineral) are based on a mixture of lime with sand or cement, often gypsum is added to the mixture. This type is environmentally friendly, but less wear-resistant. mineral plaster can be used for internal finishing works. Having a low cost of components in its composition, it is one of the most common. It is best used for finishing walls and ceilings in bathrooms.

- Polymer plasters are resistant to environments with high humidity and aggressiveness. They have strength and durability. A generally recognized disadvantage is limited vapor permeability characteristics. Therefore, this type of plaster cannot be used in the presence of a thermal insulation system based on mineral wool.

- Silicone plasters are based on the use silicone resin as part of the finishing material. They can be applied to various surfaces, including old coatings. They are UV resistant and do not attract dust. Plasters of this type have a self-cleaning effect, which manifests itself in the fact that they are able to collect water and dirt into drops, which then drain from the surface of the walls, even if it has not been wetted. This type of plaster is suitable for finishing external walls buildings located near highways and in smog areas. Silicone plasters have a long service life. They are produced in the form of mixtures that are easy to use, but have a high cost, so they are not used as often.

- Silicate plasters are based on the use of liquid glass, that is, sodium or potassium silicate. This type of plaster is not only resistant to rot and mold, but also moisture resistant. It is distinguished by fire safety and a variety of shades and tones. It can be used to simulate different kinds finishing materials. This is the most durable type of plaster that can be used for up to 60 years. If you use it for the facade, then it will cost more.

- Structural plasters are finished building mix, which has inclusions with larger particles. If the mixture is applied to the wall with a trowel, then an uneven original mark remains, so you can imitate various finishing materials, such as tree bark. This type of plaster is often used for exterior decoration. public buildings, since for finishing from the inside of the room, it will differ in roughness.

- Textured plasters are able to recreate a surface that resembles natural stone. This type of plaster is most in demand by designers. Graffito is distinguished - this is printed concrete, which has a thin layer, giving the surfaces the appearance of various finishing materials: porcelain stoneware, velvet, wood or moiré silk fabrics, and possibly natural leather. Before applying such a plaster, it is practically not required to perform certain preparatory work. So you can very easily hide any flaws, chips and cracks. This material is distinguished by high environmental friendliness, fire resistance, as it contains natural cellulose and silk fiber, fillers and mineral dyes. The material serves as an excellent sound insulator and allows any surfaces to breathe, while keeping the heat in the room.

- Plasters based on marble chips are structural coatings with high strength. For their manufacture, granite or marble granules of various fractions are used, which allows you to vary and modify the appearance. Additional additives can serve as quartz particles and special additives, which give the effect of golden shimmer. Plaster is able to resist various damages, so it is used both for outdoor and for internal walls building. Before using it, preparatory work related to the priming of the walls should be carried out, since the base may shine through.

- Venetian plasters differ from other types of expressiveness and artistic effect. Being especially popular, they represent a special art of wall painting. By applying such plaster, you can transfer any slightest vein natural stone. Due to the special wax coating, the walls are given depth and an optical illusion of silk sheen. Venetian plaster used to decorate rooms in the Baroque style.

Back to index

Stages of applying decorative plaster

Back to index

The preparatory stage before the start of decorating the walls with decorative plaster

At the stage of preparation for finishing work, a number of the following operations are performed:

- Clean all walls of the room where the repair will be carried out, removing unnecessary old wallpaper, paint or other coating.

- Thoroughly wash the surface of the walls from dust and old plaster to the purest state.

- Be sure to remove excess wall plugs fixed to the wall, otherwise they may corrode.

- Level the surface of the wall with sandpaper to remove any unevenness.

- collect all necessary materials and tools that will be required in the process of performing work.

- Finish cleaning and drying of the wall surface by applying acrylic primer and wait for it to dry completely. This will achieve maximum adhesion of the wall surface and decorative plaster.

Tools and materials that will be needed during finishing work:

- Special roller - 2 pieces with different pile.

- Spatulas - 2 pieces of different sizes made of plastic or metal.

- A drill equipped with a mixer for mixing plaster.

- Special ironing board.

- Sponge.

- Container for mixture and water.

- Decorative plaster.

- Color.

During the preparation of the wall surface for the application of decorative plaster, the temperature should be maintained at the same level. It is very important that the room was neither too hot nor too cold.

Back to index

The procedure for performing finishing work on applying decorative plaster with your own hands

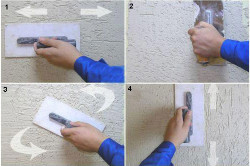

First you need to decide on the necessary shade of decorative plaster. For this purpose, part of it is diluted with a small amount of water to determine optimal composition. Then it is applied to a small piece of wall for training. This is done using a roller. The applied layer should be 3 mm. It takes two days for the textured mixture to dry. The trowel is used 20 minutes after the plaster has been applied.

After determining the required composition of the plaster, finishing work begins, associated with the following steps:

- Apply texture with a roller or sponge. Take a solution in a small amount, then apply with quick movements to the surface with a layer, the thickness of which is 2-3 mm.

- In order to avoid sharp contrasts in shades between layers, it is necessary to work at a fast pace, since the plaster can dry quickly at the edge and this will be noticeable.

- Having applied the texture, wait from 15 to 20 minutes and take a trowel moistened with water. The ironing board is carried out along wall light movements to press all the bumps.

After 2 days after the plastering of the surface, it dries completely and can be sanded, removing excess plaster particles. Sanded walls can be painted, the color is applied 2 times, the second time after 2 hours.

You can choose the option of incomplete application of plaster, and partial - to create the necessary texture of the wall. At the same time, the part where the application of decorative plaster is not planned must be protected with adhesive tape, which is removed while the texture has not yet dried.

Surface painting is carried out in 3 stages:

- Coloring of the textured part.

- Smooth surface treatment after 2 hours.

- Applying color to the plastered surface after 2 hours.

After waiting until the paint is completely dry, you can enjoy the look of the plastered surfaces. After gaining initial experience, they move on to complex plastering patterns.

Back to index

The technology of applying certain types of plaster

After the surface has been prepared to a greater or lesser extent, as required by the characteristics of a particular type of plaster, it is necessary to follow the recommendations given. At the same time, the technology for applying each type of plaster differs from one another, which should be familiarized with.

- Before applying structural plaster, the base must be reinforced with a primer, creating an intermediate layer that serves as a protection against moisture. To apply the mixture, use a spatula or trowel (trowel). Inflict structural plaster circular or straight motion. The coating gains strength in 2-3 hours, and after a week it dries completely. The surface can be varnished.

- After the prepared surface becomes even, dry and clean, it is necessary to prime the base, then start applying textured plaster in 1-2 layers. The complexity of the pattern is determined by the thickness of the layers and their number. With the help of a glazing composition, that is, translucent paints, the plastered surface is given original look. The last layer can be applied wax or special paint.

- Venetian decorative plaster is applied after leveling the base, which should be different perfect surface. When inflicted primer composition dry, they begin to plaster the surface and tint it. Layers can be applied from 5 to 12. The surface is cleaned using circular motions using fine sandpaper, then white wax is applied.

Finishing the walls is a very troublesome and responsible event. Especially if the corners and walls are uneven. Pasting such surfaces with wallpaper or decorative tiles represents difficult task and it is rarely possible to resolve it qualitatively.

In such situations, decorative plaster comes to the rescue.

At present, the dominance of dry mixes is the same free-flowing composition as the usual mass for interior decoration walls. The properties of the decor are given to it by various additives specially introduced into the recipe. It can be small stones, and even wood fibers, which give the lined surface a completely original pattern and texture.

Even an experienced plasterer, starting to finish the walls, will not be able to imagine at the beginning of work what will happen in the end. Therefore, the masters prefer to make a test application on a small flat surface before starting work, for example, on a piece of drywall. The test allows you to immediately determine the methods and techniques of coating to identify the most advantageous characteristics of the decorative coating.

Cost of decorative plaster

The presented material has many varieties. Depending on the composition, the price of the material in the form of a dry mixture ranges from 200 to 600 rubles per square meter. The consumption rate of the finished composition is presented by the manufacturer and indicated on the packaging. And the price of work for m 2 invited specialists is from 250 rubles.

At the same time, it should be borne in mind that the use of this method of wall finishing eliminates the need to perform a number of preparatory operations on their surfaces, which reduces the cost of the final cost of the coating. In addition, having minimal skills in finishing work, you can do it yourself, eliminating a significant part of the costs.

Types of decorative plaster

Several types of classification of such material for wall decoration are used:

- By type of binder.

- Depending on the type of filler, which determines the texture of the surface.

On the first question, you can get advice from the manager of the building materials store. The choice depends, first of all, on the texture of the finished surface and the operating conditions of the coating after application.

Depending on the filler, the classification may be as follows:

- textured surfaces. As the name implies, the finish surface is uneven. The material successfully hides almost any defects on the wall and allows self-application to the performer even with zero skills in such work. Actually, this determines the high popularity of this particular type of coating. And the price of the material is at a minimum level for this type of coating.

Plasters of this type, in turn, are divided into several varieties:

- "Lamb". This design gives an idea of a soft woolen surface when viewed from the side. It is well combined with substrates of mineral origin.

- "Fur coat". The surface is similar to the previous one, but looks like fleecy.

- "Bark beetle". When applied on a plane, grooves are formed, surprisingly resembling traces of a bark beetle, with correct selection tone texture corresponds to the aged wood.

- Structural. This type of coating is characterized by the almost absolute unpredictability of the nature of the surface that will be obtained during application. The previous option still allows you to somehow predict the result. In this case, at the beginning of work, you can be sure of only one thing - some kind of structure will still appear on the surface.

- Venetian. By their own decorative possibilities this plaster is superior to other types. One of the features of such a coating is the need to create an almost perfect flat surface, which is not always available even experienced craftsmen. The application process takes a lot of time. A distinctive characteristic is also the translucency of the material. At correct staging lighting creates the effect of an internal glow of the surface. This property allows you to design solutions, in which the image on the wall looks like in a haze or fog.

In addition to the types of decorative plaster mentioned here, others are also produced. All of them differ in the nature of the fillers that imitate one or another surface that is inaccessible at a cost. Such characteristics can be imitation wood or silk fabric.

These materials also include colored plaster, produced in a wide range of tones.

Do-it-yourself plaster wall decoration

With the exception of some cases (application of a Venetian coating), plastering work is quite simple and any developer, if there is time and desire, tends to do this work on their own. The desire is quite reasonable and understandable, but you need to take into account a number of circumstances, which are outlined below:

- You need to carefully consider the selection of material. Here, the advice of an experienced specialist is not only desirable, but also mandatory. And it would be better if it was not a store manager responsible for sales, but an uninterested person from the outside. Ideally, it is better to see a sample of the execution of a particular interior. The calculation of the amount of material based on the recommendations of the manufacturer is not always correct. In an effort to assure the buyer of economic efficiency, He shows minimum flow, which is not always achievable under real conditions. Therefore, it is better to purchase the amount of material with a small margin.

- If there are no gross defects on the surface to be coated, fine finish can be neglected. Only rough chips and cracks should be repaired. The rest will be effectively eliminated by a layer of plaster, for which it was originally intended. But the application of a primer is mandatory - it significantly improves the adhesion of the plaster composition to the wall surface. It is generally accepted that the finer the structure of additional inclusions, the higher the surface quality should be.

- After the final drying of the primer, and it needs at least half a day for this, you can start plastering. With a complete lack of experience, no instructions, including videos, will help. But a lot of time to master the profession is not required. It is only necessary to start work from the least important place, for example, where the furniture will subsequently stand. It is also useful to practice on foreign material from waste building materials.

- At the end of the application of plaster, it can be given additional charm by adding additional relief, for which you will need additional tools. The untinted surface can be painted additionally, choosing the paint to your liking. This method is used to ensure uniformity of tone throughout the room, which is often impossible with the inevitable frequent kneading of the plaster composition.

Plaster is generally a waterproof coating. Therefore, it can be washed without fear. In this case, you should refrain from using aggressive detergents. Soft detergent it is used with elastic sponges, hard brushes and products containing abrasives are not applicable for the care of such a coating - the surface quickly loses its appearance, becomes matte due to the large number of scratches. As additional protection the surface is covered with a thin layer of wax, which protects it from moisture, but not from mechanical damage.

If you want to change the interior, the walls can be repainted, and if you plan to use wallpaper, the walls can be additionally plastered.

Plaster tool

Tools and accessories for professionals are quite diverse. It should ensure not only the productivity of work, but also their quality.

The range of tools used largely depends on the choice of the nature of the coating. In the very simple version can do without minimum set from spatulas different size. You will also need a trowel, and for more complex options it is desirable to use textured rollers. If surface painting is envisaged, you need to stock up a painting tool.

Applying plaster to the wall

How to make decorative plaster with your own hands? For self-execution by a person without experience, a coating of the bark beetle type can be recommended. It does not require careful preparatory measures. Due to its texture, it is not necessary to diligently align it during the application process. To work with such material, several spatulas of various widths and a small skill in plastering are enough. It is almost impossible to spoil the bark beetle. The technology involves manufacturing in various versions, which directly depends on the size of the inclusion grains. Larger ones will require a thicker coating layer.

The device of the "Venetian" without a solid knowledge of skills is impossible. When performing it, it is necessary to apply several ideally even layers of plaster on a perfectly prepared surface, each with its own properties.

Silicone materials also require special skills. This is painstakingly delicate work that requires incredible patience and artistic inclinations. But the result also corresponds to the invested work.

Applying decor to the wall can be done in the following order:

- In accordance with the instructions on the packaging of the mixture, a solution of the desired consistency is prepared. Its quantity should provide for the possibility of developing at a time. Additional stirring with the addition of water is not possible - the thickened residue will have to be thrown away.

- A spatula and a grater become a universal tool. The applied layer of plaster is evenly distributed over the surface. As soon as the mass shows the first signs of hardening, it must be rubbed with a grater, while creating a pattern.

- For beginners in this business, there are several simple tricks that allow you to get a beautiful look with simple operations. decoration. This can be grouting with undulating movements, beveled or straight lines that mimic rain, various closed curves or intersecting stripes. Movements during the performance of work must be confident, soft, not allowing corrections.

- An interesting surface texture can be obtained by using the most unexpected items, from crumpled paper to brushes or washcloths. Most in a simple way is the use of textured rollers with various patterns. Given the limited hardening time of the plaster, the drawings also need to be done as quickly as possible, there will be no opportunities for correction.

- After 15 - 20 minutes after drawing the pattern, the coating begins to lose its luster, which indicates the beginning of the crystallization of the solution. It is necessary not to miss this moment, and walk along the surface with a wet trowel, smoothing out irregularities and removing too sharp changes in the relief. The tool needs to be cleaned more often and moistened abundantly.

- To separate sections of the coating with different textures, it is advisable to use construction tape. It must be removed before the applied mortar has cured to ensure a clean, tear-free interface line.

- Complete drying of the solution occurs within a day. After this time, you need to treat the surface with a fine emery cloth. In this way, excessively protruding parts and uneven coatings are removed.

- A protective coating in the form of varnish or wax is applied to the surface approximately three days after the decorative layer is applied. Before applying it, you need to carefully clean the surface of dust using a vacuum cleaner.

- When finishing exterior walls, a concrete-like surface using river pebbles is popular. After applying the composition to the wall, when it shows the first signs of hardening, you need to wash off a small part of the outer layer of the solution with a wet paint brush. The pebbles exposed at the same time are a wonderful decorative design for the wall.

Decor in alternative ways

To give decorative properties putty coating, you can use the following methods:

- Purchase a dry putty mixture and dilute it with water, taking into account the recommendations on the package. The most convenient are materials based on gypsum or cement. Possessing high strength properties, they allow you to successfully level out irregularities on the base.

- For the base layer, a thickness of 2 mm is sufficient, there is no need for careful leveling of the surface, since the decor will visually hide almost any irregularities.

- In the process of creating a textured surface, you can use various tools and techniques. A common way is to use a spatula or trowel

- Various stamps and embossed rollers with ready-made patterns are widely used

As a finishing operation, surface painting is most often performed. It is produced paint roller in two passes, the first time - with a long pile, the second - with a short one. Such a coating best highlights the texture of the finish.

Texture elements are applied to the front layer of the same putty. Its thickness should not exceed 3 mm. Otherwise, cracking during operation is possible.

Drying of the putty layer is mandatory when closed doors and windows. Drafts are not allowed. Accelerating the process by turning on the heaters can lead to cracking and collapse of the finish layer. The essence of the process is the crystallization of the mass finishing material in which air moisture also takes part. Therefore, its premature removal will lead to disruption of the process.

As you can see from the data above, the process of finishing with decorative plaster can be very simple, even easier than creating a smooth base surface. But individual materials and methods require special attention and skill, as well as artistic taste. Realistically assess your strengths and capabilities. I wish you success!